The printing industry is constantly evolving, driven by demands for faster turnaround times, enhanced print quality, and more sustainable practices. In the realm of UV curing, a significant technological leap has been the widespread adoption of LED UV systems, moving away from traditional mercury-based lamps. This transition is not merely about swapping one light source for another; it represents a fundamental shift in performance, efficiency, and application capabilities, particularly within the demanding narrow web offset printing sector.

Narrow web printing, often used for labels, flexible packaging, and specialty applications, requires precision and speed. The curing process is a critical bottleneck, directly impacting print speed, ink adhesion, and the final product’s durability. Understanding the performance differences between LED UV and traditional UV curing is paramount for printers looking to optimize their operations.

Understanding UV Curing: The Basics

Before diving into the comparison, let’s briefly recap how UV curing works. Ultraviolet (UV) curing is a photochemical process that uses high-intensity UV light to instantly dry or cure inks, coatings, and adhesives. The UV light initiates a photoinitiator within the ink or coating, causing rapid polymerization – a cross-linking of molecules that transforms the liquid into a solid, durable film. This instant curing allows for immediate handling of printed materials and enables faster printing speeds.

Traditional UV curing systems typically employ mercury vapor lamps. These lamps emit UV light across a broad spectrum, including wavelengths that are not always efficiently used for curing. They require significant power, generate considerable heat, and have a limited lifespan, necessitating frequent replacement.

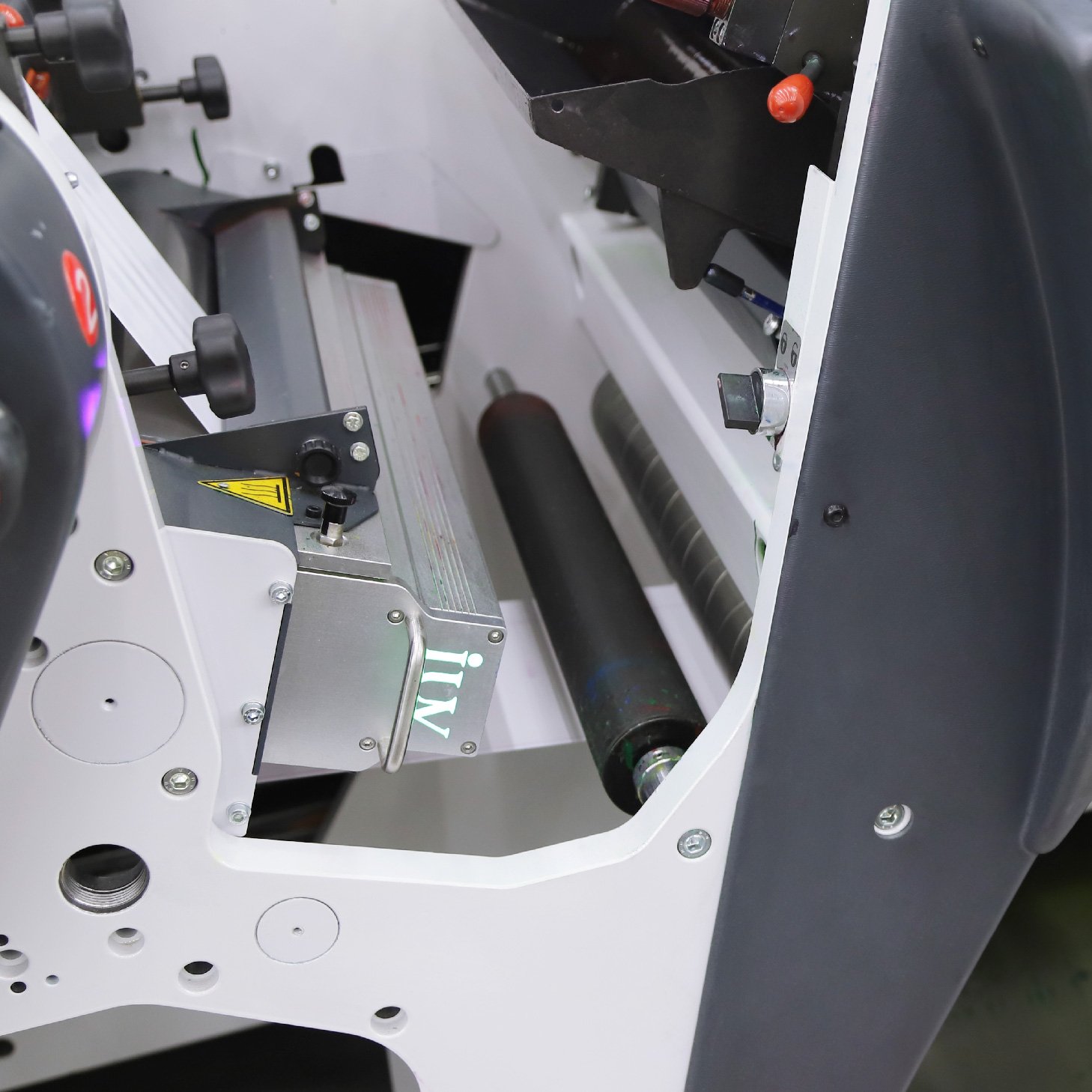

LED UV curing systems, on the other hand, utilize Light Emitting Diodes (LEDs) as the UV light source. LEDs emit UV light at specific, narrow wavelengths that are precisely matched to the photoinitiators in UV-curable inks and coatings. This targeted emission is a key differentiator.

Performance Differences: Key Metrics in Narrow Web Offset

When we talk about performance in narrow web offset printing, several factors come into play. The differences between LED UV and traditional UV systems become apparent when examining these metrics.

Energy Efficiency and Consumption

One of the most striking advantages of LED UV systems is their remarkable energy efficiency. Traditional mercury lamps are notoriously power-hungry, drawing significant wattage even when not actively curing. They also require warm-up and cool-down periods, during which they consume energy without performing useful work.

LEDs, conversely, are highly energy-efficient. They consume a fraction of the power required by mercury lamps. Furthermore, LEDs provide instant on/off capability. This means energy is only consumed when printing is actually taking place, leading to substantial cost savings on electricity bills. For a narrow web printer operating multiple presses, this efficiency translates directly to improved profitability.

Heat Generation and Substrate Compatibility

Heat is a critical consideration, especially when printing on heat-sensitive substrates commonly found in narrow web applications, such as certain films and thin papers. Traditional mercury lamps generate a large amount of infrared radiation (heat) along with UV light. This excess heat can cause substrate distortion, ink spread, and even damage to the material, limiting printing speeds and substrate choices.

LED UV systems emit very little infrared radiation. The primary energy output is in the specific UV wavelengths needed for curing. This results in significantly lower heat transfer to the substrate. This cooler curing process opens up a wider range of substrate possibilities, including delicate plastics and foils, without compromising print quality or requiring complex cooling systems. This enhanced substrate compatibility is a game-changer for label and flexible packaging printers.

Curing Speed and Quality

While both systems cure UV inks, the efficiency of the curing process can differ. Traditional UV lamps emit a broad spectrum, some of which may not be fully utilized by the photoinitiators. This can sometimes lead to incomplete curing or require higher lamp power to achieve desired results.

LED UV systems, with their precisely targeted wavelengths, are highly efficient at activating the photoinitiators. This leads to a more complete and consistent cure. This improved curing can result in enhanced ink adhesion, superior scratch and chemical resistance, and a more robust final product. The consistency of LED output also contributes to a more uniform cure across the entire print width, minimizing variations in print quality.

Lamp Lifespan and Maintenance

The lifespan of a UV lamp is a significant factor in the total cost of ownership and operational efficiency. Traditional mercury lamps have a relatively short lifespan, typically ranging from 500 to 2,000 hours. They degrade over time, meaning their UV output diminishes, requiring more frequent lamp replacements and adjustments to maintain consistent curing.

LED UV systems boast an exceptionally long lifespan, often rated for 20,000 to 50,000 hours or even more. This means they can operate for many years without needing replacement. The consistent output of LEDs throughout their lifespan also eliminates the need for frequent lamp adjustments and reduces downtime associated with lamp changes. This extended lifespan and reduced maintenance translate to lower operating costs and increased press uptime.

Environmental Impact and Operator Safety

From an environmental perspective, the energy efficiency of LED UV systems alone makes them a more sustainable choice. They consume less electricity, leading to a reduced carbon footprint. Furthermore, mercury lamps contain hazardous materials and require special disposal procedures. LED UV systems are mercury-free, making them a safer and more environmentally responsible option.

From an operator safety standpoint, the reduced heat output from LED UV systems contributes to a safer working environment. The targeted UV output also means that less stray UV light is emitted, and the spectrum is often less harmful to the human eye compared to the broad spectrum of mercury lamps. Many modern LED UV systems also incorporate features like shutter controls and interlocks for added safety.

Spectrum Control and Ink/Coating Innovation

The ability to precisely control the UV spectrum is a key advantage of LED technology. This precise control allows ink and coating manufacturers to develop new formulations optimized for specific LED wavelengths. This can lead to faster cure speeds, improved adhesion on challenging substrates, and the development of entirely new functional coatings with properties like enhanced abrasion resistance, high gloss, or matte finishes.

While traditional UV systems offer a broad spectrum, LED UV provides a level of customization that drives innovation in ink and coating chemistry, pushing the boundaries of what’s possible in narrow web printing.

Applications in Narrow Web Offset Printing

The advantages of LED UV curing are particularly well-suited for the diverse applications within narrow web offset printing:

- Labels: From wine and spirits bottles to food and beverage packaging, labels require durability, excellent print quality, and often vibrant colors. LED UV curing ensures inks and coatings withstand handling, moisture, and temperature fluctuations. The ability to print on a wide range of label stocks, including sensitive films, is also crucial.

- Flexible Packaging: For short to medium runs of flexible packaging, LED UV offers rapid curing of inks and coatings, enabling immediate handling and further processing. Its compatibility with various plastic films is essential for this market.

- Specialty Printing: This includes printing on items like tickets, coupons, bank cards, and other transactional or promotional materials. Precision, speed, and the ability to apply special effects or functional coatings are critical, all of which are enhanced by LED UV.

- In-mold Labels (IML): LED UV plays a role here by enabling the curing of inks and coatings onto the plastic films used for IML applications, ensuring durability and excellent adhesion during the molding process.

Challenges and Considerations

While the benefits are substantial, there are considerations when transitioning to LED UV systems:

- Initial Investment: The upfront cost of LED UV curing systems can be higher than traditional UV systems. However, this investment is often recouped quickly through energy savings, reduced maintenance, and increased productivity.

- Ink and Coating Formulation: Printers need to ensure their inks and coatings are compatible with the specific wavelengths emitted by their LED UV system. While a wide range of LED-compatible inks is now available, some legacy formulations may not be suitable.

- Wavelength Specificity: Different LED UV systems emit light at different wavelengths (e.g., 395 nm, 365 nm, 385 nm). It’s important to match the LED wavelength to the photoinitiators in the chosen ink or coating for optimal curing.

Conclusion: The Future is LED UV

The performance differences between LED UV curing systems and traditional UV systems in offset printing are significant and clearly favor LED technology, especially in the fast-paced narrow web market. The enhanced energy efficiency, reduced heat generation, longer lifespan, improved print quality, and environmental benefits make LED UV a compelling choice for printers looking to stay competitive.

As the demand for faster, more efficient, and sustainable printing solutions continues to grow, the adoption of LED UV curing systems in narrow web offset printing is not just a trend; it’s a strategic imperative for businesses aiming to optimize their operations and deliver superior results in an ever-evolving industry.