The printing industry is in constant evolution, seeking ways to improve efficiency, enhance product quality, and reduce environmental impact. A significant area of innovation lies in UV curing technology, the process of using ultraviolet light to instantly dry inks, coatings, and adhesives. For years, traditional mercury-based UV lamps were the standard. However, a new contender, LED UV curing, is rapidly gaining traction. This article delves into the critical differences between LED UV and traditional UV curing systems, examining their impact on cost, quality, and sustainability, with a particular focus on narrow web, flexographic, and offset printing applications.

Understanding the Core Technology

Traditional UV curing systems utilize mercury vapor lamps. These lamps emit a broad spectrum of UV light, including UVA, UVB, and UVC wavelengths, along with significant amounts of heat and infrared radiation. The curing process relies on the high energy output from these lamps to initiate the photopolymerization of UV-curable inks and coatings. While effective, this technology comes with inherent limitations related to energy consumption, heat generation, and lamp lifespan.

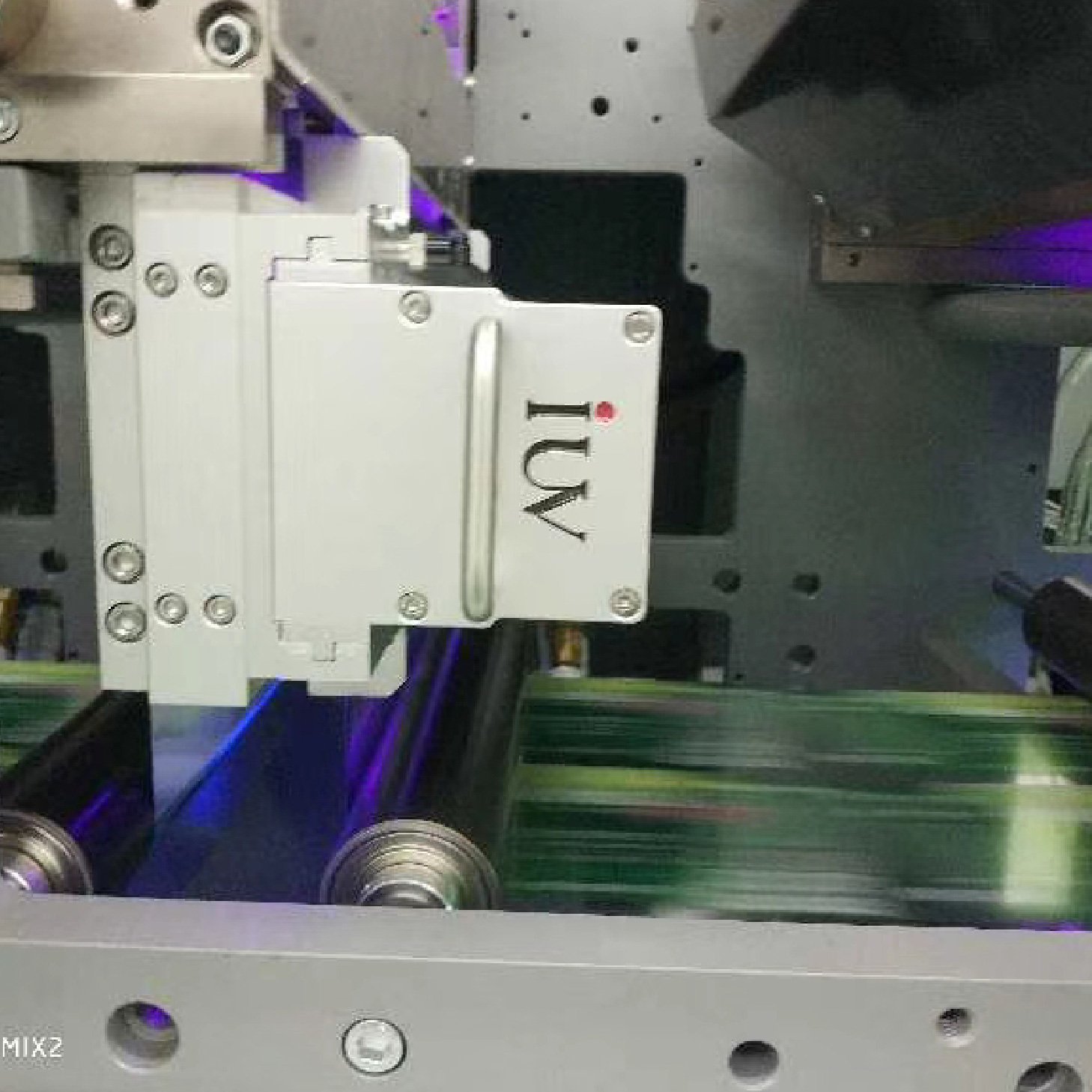

LED UV curing, on the other hand, employs light-emitting diodes (LEDs) as the UV source. LEDs emit a very narrow band of UV light, typically in the UVA spectrum (around 365 nm, 385 nm, 395 nm, or 405 nm). This targeted emission is highly efficient for curing specific UV-reactive chemistry. The technology is characterized by its long lifespan, low heat output, instant on/off capability, and precise wavelength control.

Cost Considerations: A Closer Look

When evaluating new printing equipment, cost is always a primary driver. This includes initial investment, operational expenses, and maintenance.

Initial Investment:

Historically, traditional UV systems were less expensive to purchase upfront. However, the cost gap has narrowed considerably. The price of LED UV systems has decreased as the technology has matured and become more widespread. For narrow web flexo and offset presses, the integration cost of LED UV can now be competitive, especially when factoring in long-term benefits.

Operational Costs:

This is where LED UV systems truly shine. Traditional mercury lamps consume a substantial amount of electrical energy, not just to produce UV light but also to maintain the high temperatures required for their operation. They also generate considerable heat, which necessitates cooling systems, further increasing energy demands. Many traditional UV lamps have a warm-up time, meaning the press might be running at reduced speed or idling while the lamps reach optimal temperature.

LED UV systems are significantly more energy-efficient. They consume up to 70-80% less energy than traditional UV lamps. Because they emit light only when needed and have no warm-up or cool-down period, they can be switched on and off instantly. This is a major advantage for short print runs or intermittent printing, where presses are frequently stopped and started. The reduced heat output also lowers the demand on pressroom climate control systems.

Maintenance and Lamp Replacement:

Traditional mercury lamps have a finite lifespan, typically ranging from 1,000 to 3,000 hours of operation. They degrade over time, meaning their UV output decreases, leading to inconsistent curing and potential quality issues. Lamp replacement is a recurring expense, and the disposal of mercury-containing lamps also involves specific environmental protocols and costs.

LEDs have an exceptionally long operational life, often exceeding 20,000 to 50,000 hours. This virtually eliminates the need for frequent lamp replacements. The consistent output of LEDs also ensures stable curing performance throughout their lifespan, reducing waste from rejected jobs.

Quality Implications: Precision and Performance

The quality of printed output is paramount. Both LED UV and traditional UV curing can produce high-quality results, but they offer different advantages.

Ink and Coating Performance:

Traditional UV systems, with their broad spectrum output, can cure a wide range of UV-curable inks and coatings. However, the heat generated can sometimes affect sensitive substrates or inks, leading to issues like blistering or ink spread. The inconsistent UV output as lamps age can also lead to variable cure levels.

LED UV systems, with their precise wavelength control, are highly efficient at curing specific UV chemistries formulated for them. This allows for better control over the curing process. The lower heat output is particularly beneficial for heat-sensitive substrates commonly used in label printing, such as thin films or delicate papers. It also allows for the use of inks and coatings with lower viscosity, which can improve printability and dot gain. Consistent UV output ensures reliable curing, job after job, contributing to excellent color consistency and sharpness.

Substrate Versatility:

The lower heat output of LED UV systems opens up possibilities for printing on a wider array of substrates that might not withstand the intense heat of traditional UV lamps. This is a significant advantage in the label and flexible packaging sectors where specialized materials are often employed. From thin plastics to certain types of paper and even some biodegradable materials, LED UV offers greater substrate compatibility.

Drying Speed and Throughput:

Both technologies offer instant curing, allowing for immediate handling and finishing of printed materials. However, the efficiency and intensity of LED UV systems can sometimes enable faster press speeds, particularly when optimized with suitable inks and coatings. This can lead to higher production throughput.

Sustainability: An Environmental Imperative

The printing industry faces increasing pressure to adopt more sustainable practices. Both LED UV and traditional UV curing offer environmental benefits over older drying technologies like hot air or solvent-based inks, but LED UV systems present a more compelling case for sustainability.

Energy Consumption:

As mentioned earlier, LED UV systems consume significantly less energy. This translates directly into a lower carbon footprint for the printing operation. Reduced energy use not only benefits the environment but also leads to substantial cost savings for the printer.

Waste Reduction:

The consistent and efficient curing provided by LED UV systems minimizes the risk of under-curing or over-curing, which are common causes of print defects and waste. The longer lifespan of LEDs also means less waste associated with lamp disposal. Furthermore, the ability to print on a wider range of substrates with LED UV can reduce the need for special, potentially less sustainable, materials.

Mercury-Free Technology:

Traditional mercury lamps contain a hazardous substance. Their disposal requires special handling and is subject to environmental regulations. LED UV systems are mercury-free, eliminating this environmental concern and simplifying disposal processes.

VOC Emissions:

Both UV curing technologies inherently reduce or eliminate Volatile Organic Compound (VOC) emissions compared to traditional solvent-based inks, as UV inks are 100% solids that cure via polymerization, not evaporation. However, the overall efficiency and reduced energy consumption of LED UV contribute to a more environmentally friendly printing process.

Specific Applications: Narrow Web, Flexo, and Offset

Narrow Web Flexographic Printing:

In the label printing sector, narrow web presses are ubiquitous. Here, the ability to handle heat-sensitive substrates, achieve high print quality for intricate designs, and maintain production efficiency is critical. LED UV curing systems offer advantages in all these areas. They allow for printing on thin films and papers without distortion, ensure sharp dot reproduction for fine text and graphics, and their instant on/off capability is perfect for the stop-and-start nature of short-run label production. The cost savings and reduced maintenance are also significant benefits for label converters.

Flexographic Printing (Wider Web):

For wider web flexographic applications, such as flexible packaging, LED UV offers similar benefits. The ability to cure efficiently at high speeds is essential. The lower heat generation is crucial for multi-layer packaging materials where heat can cause delamination or affect barrier properties. The consistent cure ensures that inks and coatings meet the stringent requirements for food safety and durability.

Offset Printing:

In offset printing, particularly for sheetfed applications, LED UV systems are increasingly being adopted. They enable printers to achieve instant drying of inks and coatings on a variety of paper and board stocks, allowing for immediate finishing operations like cutting, folding, and stacking. This significantly speeds up job turnaround times. The lower heat generation is beneficial for printing on thicker boards or heat-sensitive materials. For narrow web offset presses, the advantages mirror those seen in flexographic narrow web printing.

Making the Transition: What to Consider

When considering a switch to LED UV curing, printers should evaluate their current ink and coating suppliers to ensure compatibility. While many UV-curable formulations can be adapted for LED curing, specific chemistry designed for LED wavelengths will offer the best performance. Press manufacturers also offer retrofit kits for existing equipment, allowing printers to upgrade without purchasing an entirely new press. Careful consideration of the specific wavelengths and power output required for your typical print jobs is also important to ensure optimal curing.

Conclusion

The comparison between LED UV curing systems and traditional UV curing systems reveals a clear trend towards LED technology. While traditional UV lamps have served the industry well, the advancements in LED technology offer compelling advantages in terms of cost-efficiency, operational savings, enhanced print quality, and superior sustainability. For narrow web flexographic, flexographic, and offset printers looking to improve their competitive edge, reduce their environmental impact, and achieve consistent, high-quality results, investing in LED UV curing systems represents a forward-thinking and strategic decision. The long-term benefits in terms of reduced operating costs, minimized maintenance, and improved environmental performance make LED UV a powerful tool for the modern print shop.