Navigating the landscape of food packaging, the demand for safe, compliant, and high-quality printing solutions has never been greater. A critical element in achieving these standards, particularly with the increasing use of UV-curable inks, is the curing technology employed. When it comes to inks designed for food packaging, the term “low-migration” is paramount. This refers to inks formulated to minimize the transfer of components from the printed ink film to the packaged food product. Achieving effective and safe curing of these low-migration inks hinges on selecting the right technology, and in today’s market, LED UV curing systems stand out as a leading solution.

The Challenge of Low-Migration Inks

Low-migration inks are engineered with specific chemical compositions to ensure that substances within the ink do not leach into food. This often means using monomers and photoinitiators that are less prone to migration. However, these same low-migration properties can sometimes present challenges for traditional curing methods. Curing is the process by which liquid ink is transformed into a solid, durable film, typically through a chemical reaction initiated by UV light. For low-migration inks, incomplete curing can be a significant concern, as unreacted components are more likely to migrate.

Traditional UV Curing vs. LED UV Curing

For decades, mercury-vapor lamps were the standard in UV curing. These lamps emit a broad spectrum of UV light, including UVA, UVB, and UVC, as well as visible light and heat. While effective for many applications, mercury lamps have drawbacks. They consume substantial energy, generate significant heat, have a limited lifespan, and require frequent replacement. Furthermore, their broad spectrum can sometimes lead to over-curing or unwanted side reactions, which can be problematic for sensitive low-migration ink formulations.

LED UV curing, on the other hand, utilizes light-emitting diodes. These diodes emit UV light at very specific, narrow wavelengths. This targeted emission offers several advantages. For low-migration inks, the ability to precisely match the LED’s output to the absorption spectrum of the photoinitiators in the ink is a game-changer. This ensures efficient energy transfer and more complete curing.

Advantages of LED UV Curing for Low-Migration Inks

The precision of LED UV curing translates directly into significant benefits for food packaging applications using low-migration inks:

- Optimized Curing Efficiency: By selecting LED emitters that precisely match the photoinitiator’s peak absorption wavelength, the energy transfer is maximized. This leads to faster and more complete curing of the ink film. For low-migration inks, this thorough curing is essential to minimize the potential for unreacted components to migrate.

- Reduced Heat Generation: Unlike mercury lamps, LEDs produce very little infrared radiation (heat). This is crucial for heat-sensitive substrates commonly used in food packaging, such as thin films and some paper boards. Lower temperatures prevent substrate deformation, wrinkling, or delamination, ensuring the integrity of the packaging.

- Energy Savings: LEDs are significantly more energy-efficient than mercury lamps. They consume less power to produce the same curing output, leading to lower operational costs. They also reach full intensity instantaneously, meaning energy is not wasted on warm-up periods.

- Longer Lifespan and Consistency: LED lamps have a much longer operational lifespan, often tens of thousands of hours, compared to mercury lamps which might last only a few thousand hours. This reduces downtime for lamp replacement and ensures consistent curing performance over time, which is vital for maintaining product quality and safety standards.

- Instant On/Off Capability: LEDs can be switched on and off instantaneously. This is advantageous in printing environments where print heads may not be constantly over the curing station, saving energy and reducing heat build-up.

- Environmental Benefits: With no mercury content, LEDs are an environmentally friendlier option compared to traditional mercury lamps. Their lower energy consumption also contributes to a reduced carbon footprint.

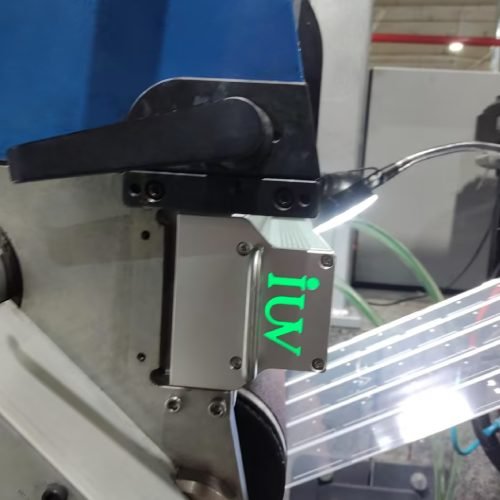

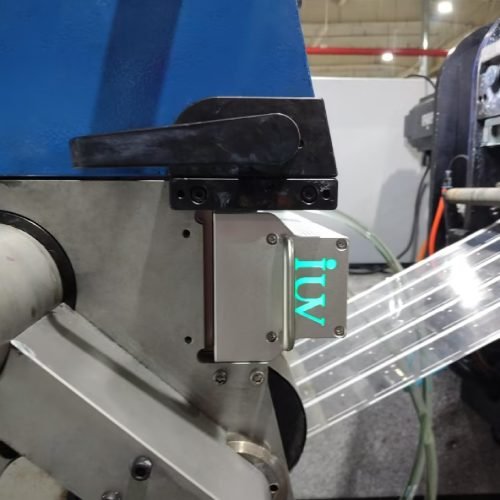

Applications in Narrow Web Printing

Narrow web printing, predominantly used for labels and flexible packaging, is a prime area where LED UV curing for low-migration inks is making a substantial impact. Whether employing flexographic, offset, or screen printing processes on these narrow webs, the ability to achieve consistent, high-quality prints that meet stringent food safety regulations is paramount.

Flexographic Printing: Flexo printing is widely used for labels and flexible packaging. In this context, low-migration UV inks are often applied to films or paper. LED UV curing systems integrated into flexo presses allow for high-speed curing, ensuring that the ink is fully cross-linked before the web is rewound or further processed. This is critical for preventing ink transfer to the inside of the roll or to adjacent packaging. The precise wavelength control of LEDs helps ensure optimal curing of the ink without damaging the flexible substrate.

Offset Printing: While traditionally more associated with sheetfed, narrow web offset printing has gained traction for specialized labels and packaging. The challenges of achieving consistent ink coverage and sharp detail are met with the enhanced curing capabilities of LED UV. For low-migration inks, the complete cure achieved with LEDs ensures that the printed graphics are durable and safe for direct or indirect food contact.

Screen Printing: Screen printing is known for its ability to deposit thick ink layers, providing excellent opacity and tactile effects. For food packaging applications requiring vibrant graphics or special finishes, low-migration UV inks are often used. LED UV curing systems can effectively cure these thicker ink layers, even at high speeds, ensuring the integrity of the print and compliance with migration limits.

Considerations for Implementing LED UV Curing

When transitioning to or specifying LED UV curing systems for low-migration ink applications in food packaging, several factors warrant careful consideration:

- Ink Formulation and Photoinitiator Selection: It is crucial to work with ink manufacturers who formulate low-migration inks specifically designed for LED curing. The photoinitiators must be matched to the specific wavelengths emitted by the chosen LED system. A mismatch can lead to inefficient curing and potential migration issues.

- Wavelength Specificity: LED UV systems are available with different peak wavelengths, commonly in the range of 365 nm, 385 nm, 395 nm, and 405 nm. The selection should be based on the photoinitiator system of the low-migration ink being used. Consultation with both the ink supplier and the curing system manufacturer is highly recommended.

- Irradiance and Dose: The intensity of the UV light (irradiance) and the total energy delivered (dose) are critical parameters for effective curing. These need to be optimized for the specific ink, substrate, and press speed. LED systems allow for precise control over irradiance, ensuring consistent energy delivery.

- Substrate Compatibility: While LEDs generate less heat, it’s still important to consider the substrate’s thermal properties and its interaction with the UV curing process.

- Regulatory Compliance: Food packaging printing must adhere to strict regulations regarding migration. Selecting compliant low-migration inks and ensuring complete curing with appropriate LED UV technology is a foundational step in meeting these requirements. Certifications and testing data from ink and equipment suppliers should be reviewed.

The Future of Food Packaging Printing

The drive for safer, more sustainable, and higher-quality food packaging continues to shape the printing industry. LED UV curing technology, with its inherent advantages in precision, efficiency, and reduced environmental impact, is at the forefront of this evolution, particularly when paired with advanced low-migration ink formulations. For label and narrow web printers seeking to meet the rigorous demands of the food industry, investing in LED UV curing systems for their low-migration ink applications is not just a technological upgrade; it’s a strategic decision that enhances product safety, operational efficiency, and market competitiveness. The ability to guarantee the integrity and safety of printed food packaging, while also achieving superior print quality, is now more attainable than ever.