The printing industry is at a critical juncture, driven by increasing consumer demand for sustainable products and stricter environmental regulations. Print shops worldwide are actively seeking ways to reduce their ecological footprint, minimize emissions, and create healthier working environments. In this pursuit, LED UV curing systems have emerged as a revolutionary technology, offering a compelling path towards eco-friendly and low-emission print operations. This shift is particularly impactful in sectors like label printing, flexographic printing, offset printing, and narrow web printing, where efficiency and environmental consciousness are paramount.

Understanding Traditional UV Curing and Its Limitations

For decades, traditional mercury lamp UV curing systems have been the standard in many printing processes. These systems utilize high-intensity mercury vapor lamps to emit ultraviolet light, which initiates a photochemical reaction in UV-curable inks, coatings, and adhesives, causing them to solidify (cure) almost instantaneously. While effective, these traditional systems come with significant drawbacks that are becoming increasingly problematic in today’s environmentally aware landscape.

Mercury lamps contain hazardous substances, posing disposal challenges and environmental risks. Their high energy consumption leads to substantial electricity bills and contributes to a larger carbon footprint. Furthermore, mercury lamps generate considerable heat, which can affect substrate stability, limit material choices, and create an uncomfortable working environment. The lamps also have a finite lifespan, requiring frequent and costly replacements. These factors, combined with the production of ozone as a byproduct, make traditional UV curing less aligned with the goals of a sustainable, low-emission printshop.

The LED UV Revolution: A Paradigm Shift in Curing Technology

Light Emitting Diode (LED) UV curing systems represent a significant technological leap forward, addressing the shortcomings of traditional mercury lamps head-on. Instead of relying on mercury vapor, LED systems use a matrix of solid-state semiconductor devices that emit UV light when an electric current passes through them. This fundamental difference unlocks a host of benefits that directly support eco-friendly and low-emission printing.

One of the most striking advantages of LED UV curing is its dramatically reduced energy consumption. Compared to mercury lamps, LED systems can use up to 70-80% less energy to achieve the same level of cure. This translates into substantial cost savings on electricity bills and a significantly lower carbon footprint for the printing operation. For print shops focused on sustainability, this energy efficiency is a game-changer, directly contributing to a greener operational model.

Environmental Advantages: Low Emissions and Reduced Waste

The environmental benefits of LED UV curing extend far beyond energy savings. Unlike mercury lamps, LED systems do not contain hazardous materials like mercury, eliminating concerns about disposal and environmental contamination. This makes them a far more responsible choice for print shops committed to minimizing their ecological impact.

Furthermore, LED UV systems are renowned for their low-heat emission. This is crucial for a variety of printing applications. In label printing and narrow web printing, where substrates can be sensitive to heat, LED curing allows for the use of a wider range of materials, including delicate films and foils, without risking distortion or damage. This flexibility in material handling can open up new product possibilities and enhance design capabilities. The reduced heat output also contributes to a more comfortable and safer working environment for print shop personnel, as it lessens the thermal load in the production area.

Another key environmental advantage is the absence of ozone generation. Traditional mercury lamps emit ozone, a harmful air pollutant that requires ventilation systems and negatively impacts air quality within the print shop. LED UV systems, by contrast, produce virtually no ozone, contributing to a healthier indoor environment and reducing the need for extensive, energy-consuming ventilation.

Enhanced Performance and Efficiency in Specific Printing Sectors

The advantages of LED UV curing are particularly pronounced in specialized printing sectors like flexographic, offset, and narrow web printing.

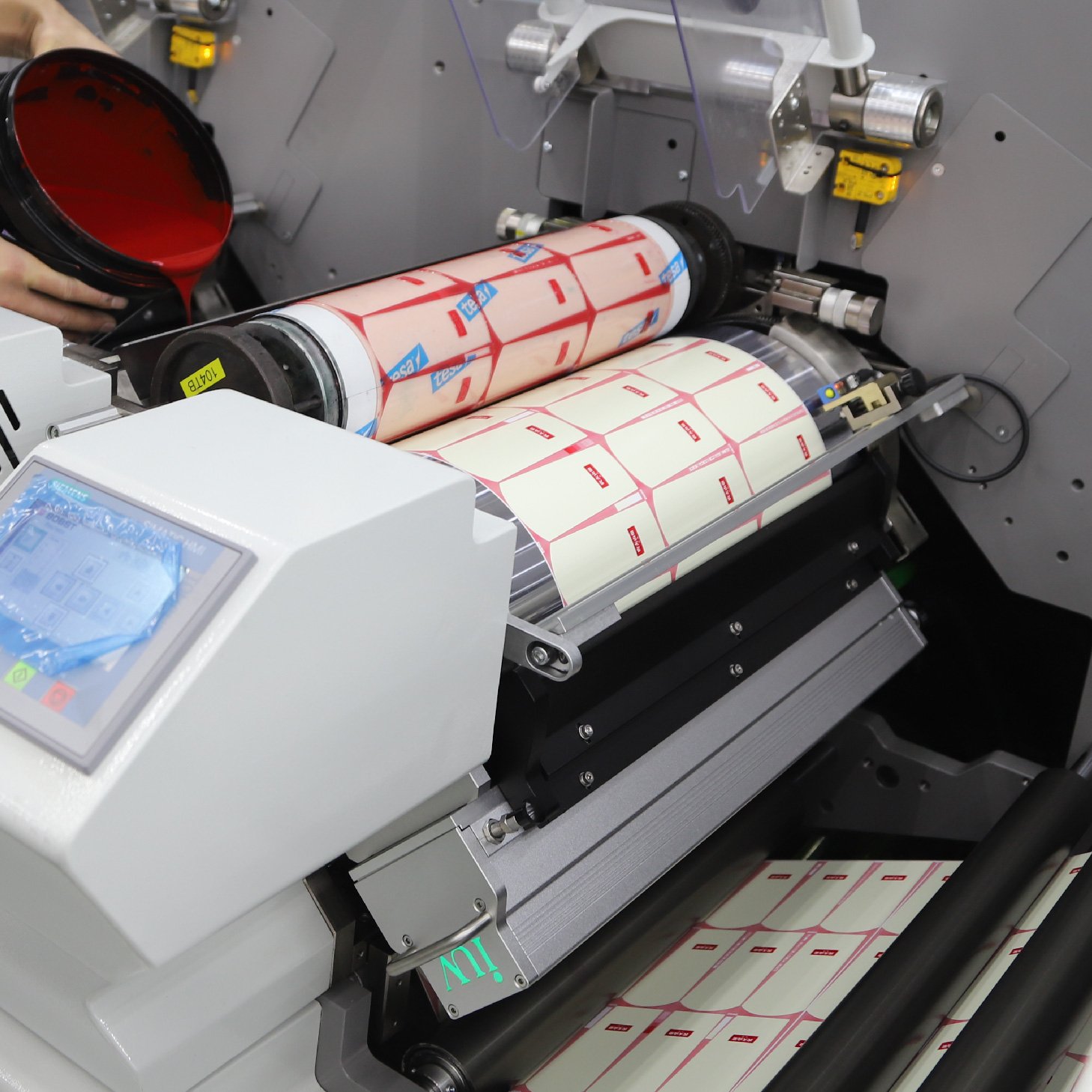

In flexographic printing, particularly for labels and packaging, the ability of LED UV to cure instantly and efficiently is critical. It allows for higher printing speeds without compromising ink adhesion or finish. The low-heat aspect is also beneficial for heat-sensitive films commonly used in flexible packaging. LED UV inks are formulated to cure rapidly under specific UV wavelengths emitted by the LEDs, ensuring sharp print quality and excellent rub resistance.

Narrow web printing, often used for producing labels, tickets, and other small-format items, benefits immensely from the compact nature and instant on/off capability of LED UV systems. This allows for quick job changes and reduces waste associated with startup and shutdown sequences. The precise control over UV output from LED lamps ensures consistent curing across the web, even at high speeds, which is essential for maintaining print quality and productivity.

Offset printing, while traditionally using different drying methods, is increasingly adopting LED UV technology for its speed and efficiency. In both sheetfed and web offset, LED UV curing enables immediate handling of printed sheets or webs, eliminating the need for inter-stage drying or long cooling periods. This speeds up the entire production workflow, from printing to finishing, and reduces the risk of ink set-off. The ability to print on a wider array of substrates, including non-porous materials like plastics, is another significant advantage offered by LED UV in offset operations.

The Economic Case for LED UV Curing

Beyond the environmental and performance benefits, the economic advantages of adopting LED UV curing systems are compelling. The significant reduction in energy consumption directly translates into lower operational costs. The extended lifespan of LED lamps, often lasting tens of thousands of hours compared to the few thousand hours of mercury lamps, means less frequent replacements and reduced maintenance expenses. This longevity also minimizes downtime associated with lamp changes, further boosting productivity.

The ability to print on a wider variety of substrates, including plastics and foils, can also lead to cost savings by reducing the need for specialized or pre-treated materials. Furthermore, the increased printing speeds and faster turnaround times enabled by LED UV curing can lead to higher throughput and greater profitability.

Making the Transition: Key Considerations

For print shops considering the transition to LED UV curing, a few key factors warrant attention. The initial investment in LED UV curing systems can be higher than for traditional systems. However, this must be weighed against the long-term savings in energy, maintenance, and consumables. Careful assessment of current production needs, substrate types, and ink formulations is crucial to select the most appropriate LED UV system.

It is also important to ensure compatibility with existing printing presses and finishing equipment. Many modern presses are designed with LED UV integration in mind, but retrofitting older machines may require specific engineering considerations. Collaboration with equipment manufacturers and UV system providers is essential to ensure a seamless integration and optimal performance.

The Future of Print is Green and Efficient

The adoption of LED UV curing systems is not just a technological upgrade; it’s a strategic move towards a more sustainable, efficient, and profitable future for the printing industry. By embracing this advanced technology, print shops can significantly reduce their environmental impact, lower operating costs, enhance productivity, and create a healthier working environment. As the demand for eco-friendly printing solutions continues to grow, LED UV curing stands out as a cornerstone technology, paving the way for a greener and more competitive print landscape. The journey towards a low-emission printshop is now more achievable than ever, powered by the innovative capabilities of LED UV curing.