In the fast-evolving world of printing, the need for faster, more efficient, and environmentally-friendly processes is greater than ever. One of the most significant technological advances in recent years is the use of LED UV curing systems. These systems have revolutionized narrow web printing, combining high-speed curing with energy efficiency and reduced environmental impact. This article delves into how LED UV curing technology works and why it’s becoming an essential part of modern flexographic, letterpress, and other narrow web printing processes.

Understanding LED UV Curing Technology

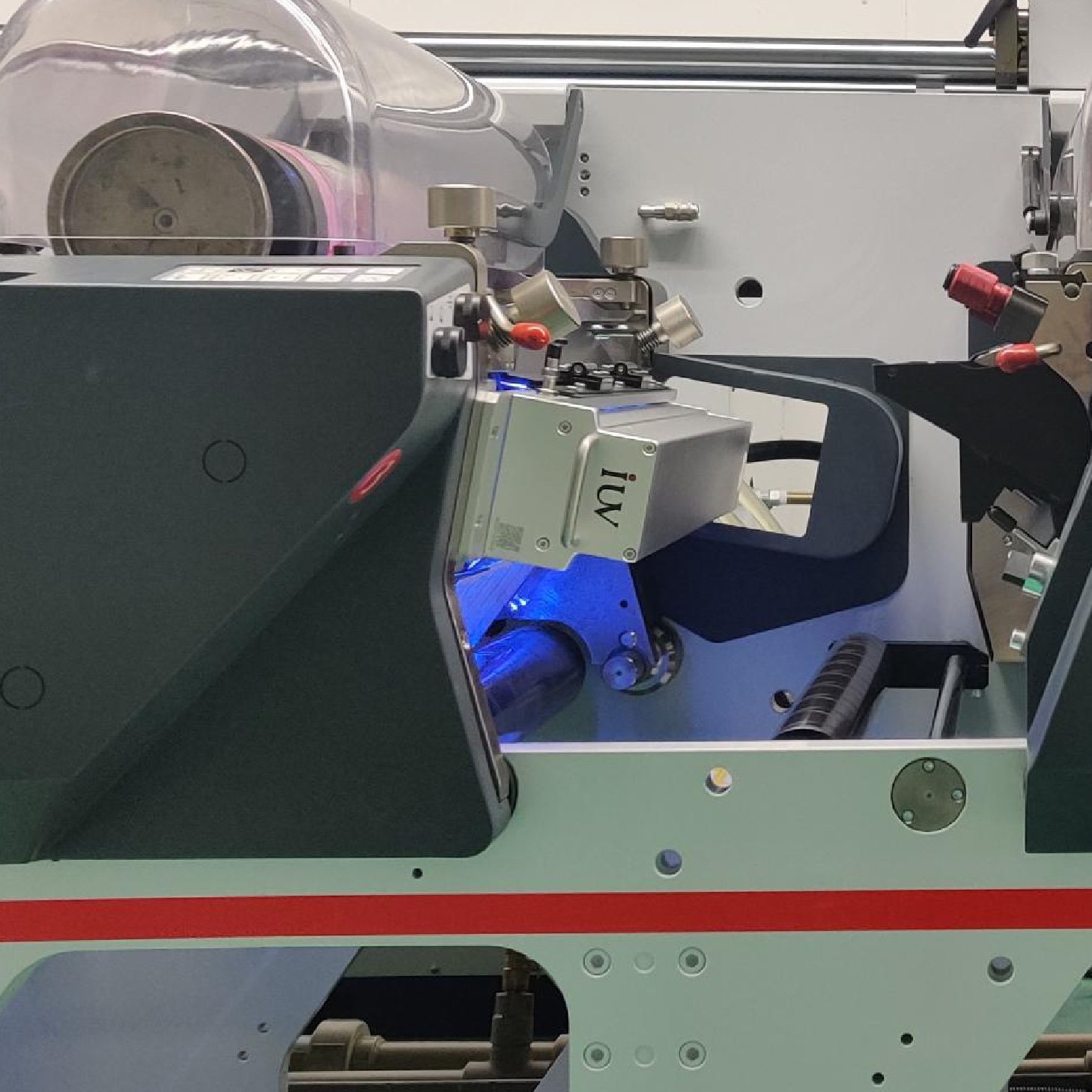

LED UV curing involves the use of ultraviolet (UV) light to instantly cure or dry ink, coatings, or adhesives as they are applied to a substrate. Unlike traditional drying methods that rely on heat or air evaporation, LED UV curing uses specialized LEDs that emit UV light at specific wavelengths. This light activates photoinitiators in the ink, causing it to polymerize and harden almost instantly.

The key advantages of LED UV curing systems are their energy efficiency, reduced curing times, and ability to print on a wider range of substrates. The technology also delivers consistent results, ensuring high-quality prints with minimal waste.

The Role of LED UV Curing in Narrow Web Printing

Narrow web printing refers to printing on smaller rolls of substrate, typically under 530 mm wide. This method is commonly used for packaging materials such as labels, flexible packaging, and flexible films, as well as other small-format prints. In narrow web printing, speed and precision are crucial for meeting the growing demands of the market.

LED UV curing technology addresses these demands by significantly speeding up the curing process. Traditional curing methods, such as air drying or conventional UV lamps, can take longer to fully dry the printed material, which may delay the production process and increase the risk of print defects. In contrast, LED UV systems allow ink to cure almost immediately, improving throughput and reducing the need for additional processing time.

Benefits of LED UV Curing Systems for Narrow Web Printers

Speed and Efficiency

One of the standout features of LED UV curing is its speed. Since the ink cures instantly when exposed to the LED light, printers can achieve a much faster turnaround time. This speed is particularly beneficial in high-volume production environments where time and efficiency are paramount. In addition to improving throughput, this rapid curing also allows for faster job changes, enabling more flexible production schedules and reduced downtime.

Moreover, LED UV curing systems require less energy compared to traditional UV lamps. The LEDs consume less power, generate less heat, and have a longer operational lifespan, which can reduce overall operating costs. For narrow web printers, this means that the systems are both cost-effective and sustainable, with lower energy consumption and reduced need for maintenance.

Superior Print Quality

LED UV curing also improves the overall print quality. The ink cures more evenly and quickly, ensuring a smooth finish with minimal risk of smudging or scuffing. This is especially important in high-precision applications such as labels, where small text, intricate graphics, and fine details need to be maintained without distortion.

Additionally, because LED UV inks cure so quickly, they are less likely to suffer from overexposure to light or air, which can lead to changes in color or texture. This results in more consistent, vibrant colors and sharper print quality throughout the entire run.

Environmentally Friendly

Environmental concerns are increasingly important in the printing industry, and LED UV curing technology offers significant eco-friendly benefits. Traditional UV lamps generate a lot of heat and require the use of mercury, which is harmful to the environment. On the other hand, LED UV curing systems produce no mercury, emit minimal heat, and are free of harmful solvents. The inks used in LED UV curing are also typically low in volatile organic compounds (VOCs), which further reduces the environmental impact of the printing process.

By switching to LED UV curing, narrow web printers can significantly reduce their carbon footprint and contribute to a more sustainable production process. Furthermore, the system’s energy efficiency helps printers comply with stringent environmental regulations and industry standards.

LED UV Curing in Flexographic and Letterpress Printing

LED UV curing is particularly advantageous for flexographic printing, one of the most commonly used methods in narrow web printing. Flexographic presses use flexible printing plates, often referred to as “flexo plates,” to transfer ink onto substrates like film, paper, and foil. With the quick curing power of LED UV systems, flexo presses can maintain high-speed operation while ensuring consistent ink adhesion, resulting in cleaner prints and less waste.

In letterpress printing, LED UV curing is also a game-changer. Letterpress involves transferring ink from raised, photopolymer plates to a substrate through direct pressure. The fast curing speed of LED UV light helps printers achieve sharp details and vibrant colors, even when printing on challenging substrates like non-porous materials. This allows for high-quality, precise prints, which are essential for applications such as premium packaging, tags, and other high-end print products.

The Flexibility of LED UV Curing Systems

One of the greatest strengths of LED UV curing systems is their flexibility. The ability to cure a wide range of ink types—whether it’s for flexo, letterpress, or other narrow web applications—makes LED UV technology adaptable to various printing needs. It can be used on a variety of substrates, including paper, plastic, films, foils, and more, without compromising quality or performance.

LED UV curing systems can also handle a variety of ink formulations, including water-based, solvent-based, and UV inks. This versatility allows narrow web printers to use a wide array of materials and inks while maintaining high-quality results.

Cost Considerations: Initial Investment vs. Long-Term Savings

While LED UV curing systems can come with a higher initial investment compared to traditional curing systems, the long-term savings often justify the cost. Reduced energy consumption, lower maintenance needs, and fewer replacement parts all contribute to a lower total cost of ownership. Moreover, the faster curing process means that printers can handle more jobs in less time, increasing productivity and profitability.

For narrow web printers that need to stay competitive in a fast-paced market, investing in LED UV curing systems is a wise decision that pays off in both the short and long term.

Conclusion

LED UV curing systems have proven to be a game-changer for narrow web printing, offering numerous benefits that enhance speed, efficiency, print quality, and environmental sustainability. Whether for flexographic, letterpress, or other narrow web applications, these systems provide faster curing times, lower energy consumption, and superior print quality, all while minimizing the environmental footprint of the printing process.

As the printing industry continues to evolve, LED UV curing technology will undoubtedly play a central role in shaping the future of narrow web printing. With their energy efficiency, superior performance, and adaptability to various ink types and substrates, LED UV systems are set to become the standard in the industry.