Modern label printing demands speed, efficiency, and exceptional quality. For multi-layer label applications, achieving these goals presents unique challenges. These intricate labels often require multiple ink layers, special coatings, and precise registration, all while maintaining high production throughput. The technology that has become indispensable in meeting these demands is LED UV curing.

Traditionally, UV curing systems relied on mercury vapor lamps. While effective, these lamps generated significant heat, had a limited lifespan, and consumed a considerable amount of energy. The advent of Light Emitting Diode (LED) UV curing technology has revolutionized the industry, offering a more sustainable, efficient, and versatile solution, particularly for high-speed, multi-layer label production.

The Mechanics of LED UV Curing

LED UV curing systems utilize semiconductor diodes that emit ultraviolet light when an electric current passes through them. Unlike broad-spectrum mercury lamps, LEDs emit light at specific wavelengths. This targeted emission is a significant advantage. For ink and coating formulations, this means more efficient energy transfer, leading to faster and more complete curing. The specific wavelengths typically used are in the UVA range (365nm, 385nm, 395nm, 405nm), which are highly effective for initiating the photoinitiators present in UV-curable inks and coatings.

The curing process itself is a photochemical reaction. Photoinitiators within the ink or coating absorb the UV light. This absorption triggers a chemical reaction that causes monomers and oligomers to polymerize, transforming the liquid ink or coating into a solid, durable film almost instantaneously.

Advantages for Multi-Layer Label Printing

The complexities of multi-layer labels amplify the benefits of LED UV curing. Consider a label requiring opaque white ink followed by process colors and then a spot color or a special effect varnish. Each layer must be cured before the next is applied to prevent smudging, misregistration, or ink bleed.

1. Instant Curing and Enhanced Productivity: LED UV systems offer instant curing, often in fractions of a second. This allows for immediate overprinting or lamination of subsequent layers. In high-speed narrow web presses, this means presses can run at their maximum mechanical speeds without bottlenecks caused by slow ink drying. For multi-layer labels, this translates directly into higher output and reduced lead times.

2. Reduced Heat Input and Material Stability: One of the most significant advantages of LED UV is its significantly lower heat output compared to mercury lamps. Mercury lamps can generate substantial heat, which can cause substrates, especially thinner films or heat-sensitive papers, to warp, shrink, or blister. This heat can also degrade adhesives, compromising the label’s integrity. LED systems emit minimal heat, allowing for printing on a wider range of substrates without compromising material stability. This is crucial for multi-layer constructions where multiple passes through the press occur.

3. Energy Efficiency and Sustainability: LED UV lamps are remarkably energy-efficient. They consume up to 70% less energy than traditional mercury lamps. Furthermore, LEDs have a much longer operational lifespan, often exceeding 20,000 hours, compared to the 1,000-2,000 hours of mercury lamps. This reduces downtime for lamp replacement and lowers overall operational costs. The lack of mercury also makes LED systems more environmentally friendly.

4. Precise Wavelength Control and Ink Performance: The ability to select specific wavelengths with LEDs allows formulators to optimize ink and coating performance. This is particularly relevant for multi-layer applications where different inks might require different curing profiles or where specific effects (like high gloss or matte finishes) are desired. The consistent, targeted output ensures reliable curing across the entire width of the print web, even at high speeds.

5. Reduced VOC Emissions: UV-curable inks and coatings are inherently low in Volatile Organic Compounds (VOCs). The rapid and complete curing process enabled by LED UV technology ensures that virtually no VOCs are released into the environment, contributing to a safer and healthier working environment and compliance with environmental regulations.

Integrating LED UV in Different Printing Processes

LED UV curing systems are highly adaptable and can be integrated into various printing technologies commonly used for label production, including flexography, offset lithography, and screen printing.

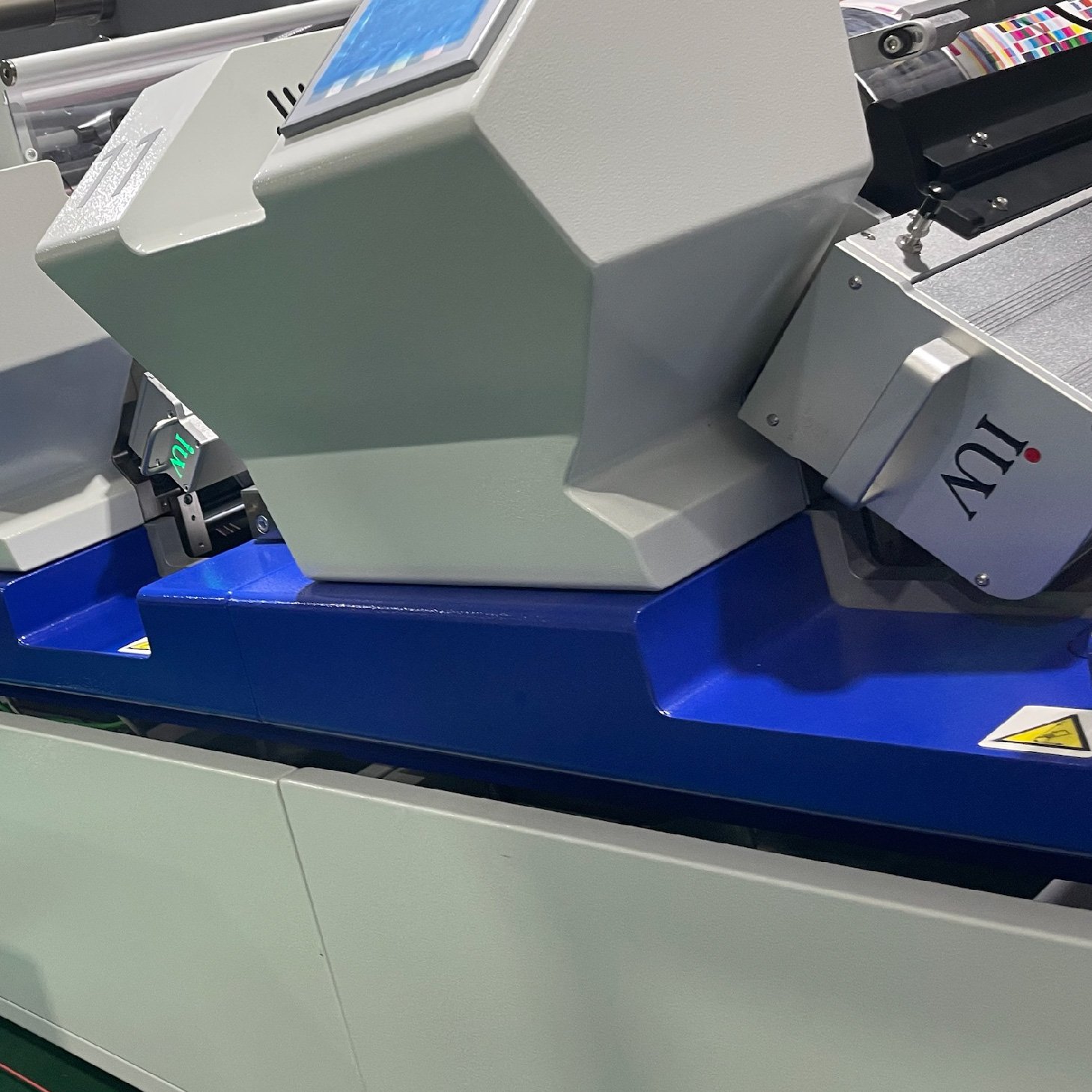

Flexographic Printing: This is perhaps the most prevalent method for narrow web label printing. Flexo presses are designed for high-speed, multi-station printing. Integrating LED UV units between print stations allows for the rapid curing of each ink layer. For multi-layer labels, this means an opaque white can be printed and immediately cured, followed by process colors, and then spot colors or varnishes, all within a single pass. The compact nature of LED UV lamps also allows them to be easily retrofitted into existing flexo presses or incorporated into new machine designs without significantly increasing the press footprint.

Offset Lithography (Sheetfed and Web): While traditionally more common for commercial printing, offset lithography is also used for certain label applications, especially where high print quality and fine detail are paramount. Web offset presses can also benefit from LED UV curing for multi-layer designs. The ability to cure inks quickly prevents ink transfer issues between the printed sheet or web and subsequent handling or finishing processes.

Screen Printing: Screen printing is ideal for applying thicker ink layers, special effects, and durable finishes. For multi-layer labels requiring tactile effects, metallic inks, or high-build varnishes, screen printing combined with LED UV curing offers excellent results. The instant curing ensures that these specialized layers maintain their intended thickness and effect without spreading or blurring.

Ink and Coating Formulations for LED UV

The shift to LED UV curing has also driven innovation in ink and coating formulations. Printers using LED systems require inks specifically designed for the wavelengths emitted by the LEDs. These formulations contain photoinitiators that are highly sensitive to the specific UV spectrum of the LED lamps.

For multi-layer applications, it’s essential to consider the compatibility of different ink layers. The curing of each layer should not negatively impact the adhesion or appearance of subsequent layers. Formulators are developing inks with optimized cure speeds and cross-linking properties to ensure robust adhesion and excellent performance, even when printed in multiple layers. This includes inks for vibrant process colors, opaque whites, metallic effects, and protective or functional coatings.

Considerations for Implementation

When considering the implementation of LED UV curing systems for high-speed multi-layer label applications, several factors come into play:

- Wavelength Compatibility: Ensure the LED system’s wavelength output is matched to the photoinitiators in the chosen inks and coatings.

- Irradiance: The intensity of the UV light (irradiance) is critical for cure speed. Higher irradiance generally leads to faster curing.

- Dose: The total energy delivered to the ink/coating (irradiance x time) determines the degree of cure. For high-speed printing, achieving sufficient dose is paramount.

- Cooling: While LEDs produce less heat than mercury lamps, effective cooling is still necessary to maintain optimal diode performance and lifespan.

- Press Integration: The physical integration of LED UV units into the printing press requires careful consideration of space, power, and ventilation.

- Substrate: The type of substrate will influence the curing requirements and the choice of inks and coatings.

- Application Requirements: The final performance demands of the label (e.g., rub resistance, chemical resistance, outdoor durability) will dictate the type of inks, coatings, and curing parameters needed.

The Future of Label Printing with LED UV

LED UV curing technology continues to evolve, with advancements in diode efficiency, wavelength control, and integration capabilities. For the demanding realm of high-speed, multi-layer label production, LED UV curing is no longer a luxury but a necessity. It provides the speed, precision, and efficiency required to meet market demands, enabling printers to produce complex, high-quality labels with greater sustainability and cost-effectiveness. The ability to achieve instant cures between each layer empowers printers to push the boundaries of label design and functionality, ensuring that the labels of today and tomorrow are printed with unparalleled quality and speed.