In recent years, the printing industry has seen significant advancements in technology that have greatly impacted both the speed and accuracy of print processes. One of the most transformative innovations is the integration of LED UV curing systems. These systems, which utilize ultraviolet (UV) light emitted by light-emitting diodes (LEDs), have revolutionized printing methods such as flexographic printing, offset printing, and narrow-web printing. In this article, we will explore how LED UV curing technology works and its crucial role in enhancing print speed, quality, and overall efficiency in modern printing operations.

What is LED UV Curing?

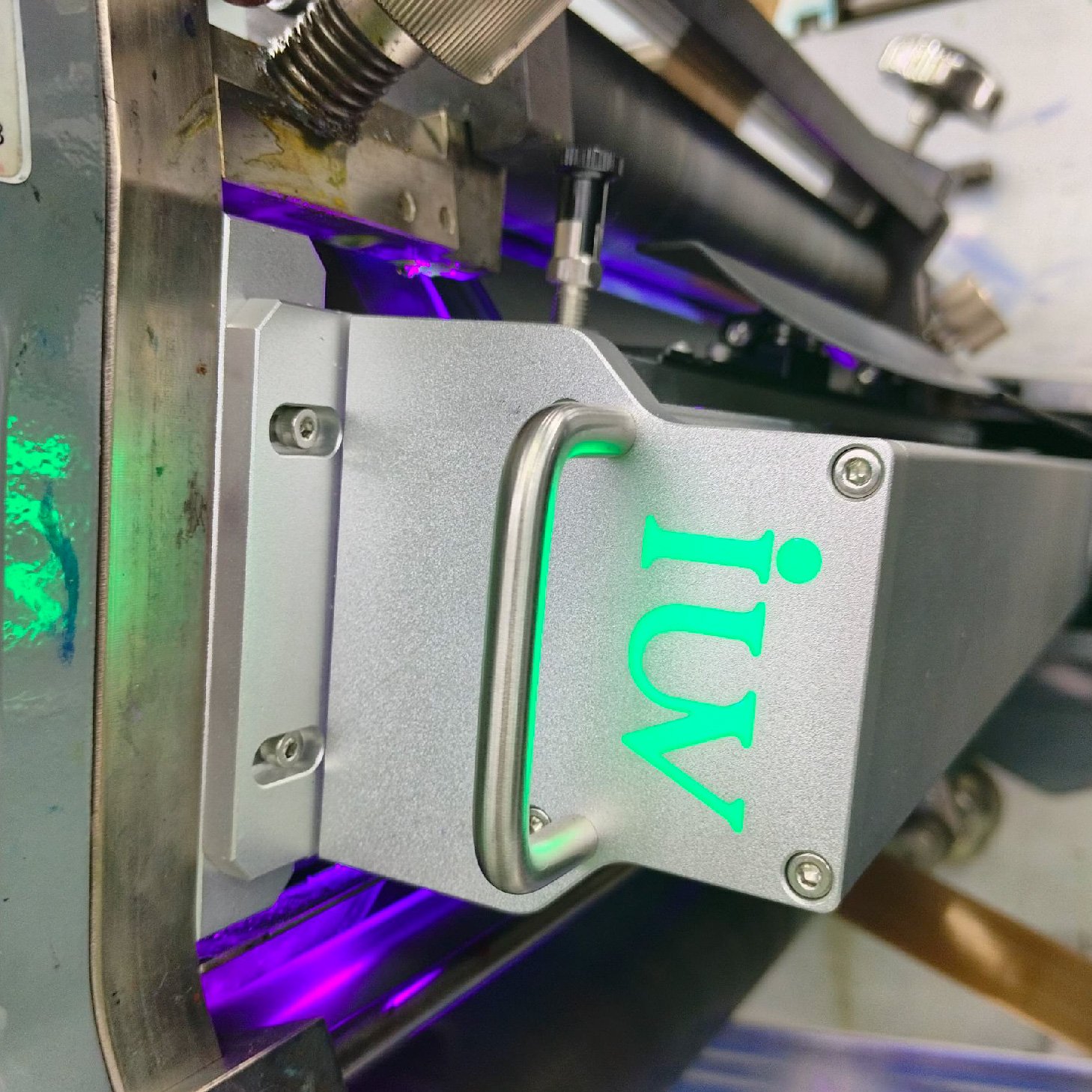

LED UV curing is a process where UV light, generated by LEDs, is used to instantly cure or dry inks and coatings on printed materials. Unlike traditional curing methods that rely on mercury vapor lamps, LED UV curing uses solid-state lighting, which is energy-efficient and environmentally friendly. The key advantage of LED UV curing is its ability to cure inks and coatings almost instantly, which significantly accelerates the printing process.

In a typical LED UV system, LED lights are positioned above the printed substrate. When the printed material passes under the LED light, the UV light causes the ink or coating to undergo a photochemical reaction, hardening or curing it. This process eliminates the need for drying time, improving throughput and reducing energy consumption.

The Role of LED UV Curing in Enhancing Print Speed

One of the primary reasons LED UV curing systems have gained popularity is their ability to dramatically increase print speed. Traditional drying methods, such as air-drying or heat-drying, require substantial time to allow inks to set and dry on the substrate. This delay can result in slower printing speeds and reduced overall productivity, especially in high-volume production environments.

LED UV curing systems, on the other hand, can cure inks almost instantly, allowing for faster printing cycles. This is particularly beneficial in high-speed printing processes such as flexographic printing and narrow-web printing. In flexographic printing, where high-quality, large-volume runs are common, LED UV curing can significantly reduce cycle times, enabling printers to complete more jobs in less time.

The ability to cure inks immediately also facilitates the use of a broader range of substrates, including materials that may not have been suitable for traditional drying methods. For example, non-porous substrates such as films, plastics, and coated papers can now be printed with LED UV curing without the risk of ink smudging or smearing. This flexibility makes LED UV curing an ideal solution for diverse printing applications across various industries.

Improving Print Accuracy and Quality

Beyond speed, LED UV curing systems also contribute to enhanced print accuracy and quality. Traditional curing methods can result in uneven drying, leading to issues such as ink blotting, distortion, and color inconsistencies. With LED UV curing, the curing process is more uniform and consistent, leading to sharper, more accurate prints with minimal defects.

LED UV curing also plays a critical role in maintaining the integrity of fine details, especially in applications that require precise and intricate designs. In flexographic printing, where intricate patterns are often used in packaging or labels, LED UV curing ensures that the ink does not spread or bleed, maintaining sharp and crisp edges. This is especially important for narrow-web printing, where the precision of the print must be flawless.

Moreover, LED UV systems offer superior adhesion properties. The cured ink bonds tightly to the substrate, reducing the risk of peeling or scratching. This is particularly useful for printing on non-absorbent materials, such as plastic films, where traditional inks might struggle to adhere properly.

Energy Efficiency and Cost-Effectiveness

Another significant advantage of LED UV curing is its energy efficiency. Traditional mercury vapor lamps used in UV curing consume a large amount of energy and generate significant heat, which can lead to higher operating costs. LED UV systems, however, consume much less energy and produce very little heat, making them more environmentally friendly and cost-effective in the long run.

The reduced heat output of LED UV systems also helps in protecting substrates from heat-related damage. For instance, delicate materials that cannot withstand high temperatures benefit from the cooler operating conditions of LED UV curing, ensuring that the substrate remains intact while the ink or coating is effectively cured.

In addition to the energy savings, the long lifespan of LED bulbs further contributes to cost reductions. LED bulbs typically last much longer than traditional mercury vapor lamps, reducing the frequency of replacements and maintenance costs.

Environmental Benefits of LED UV Curing

In an age where sustainability is a key concern across all industries, LED UV curing systems offer significant environmental benefits. First, the energy efficiency of LED UV systems reduces the carbon footprint of the printing process. By consuming less energy, printing operations can lower their overall emissions and contribute to a more sustainable production environment.

Furthermore, LED UV curing does not require the use of hazardous mercury vapor, which is a major concern with traditional UV curing systems. Mercury is toxic and requires special disposal methods, making it an environmental challenge. LED UV systems eliminate this issue entirely, offering a safer and more eco-friendly alternative.

Additionally, LED UV inks are often more environmentally friendly. These inks typically contain fewer volatile organic compounds (VOCs) compared to traditional inks, contributing to a cleaner working environment and reducing the release of harmful chemicals into the air.

Applications in Various Printing Processes

LED UV curing has found a wide range of applications in different printing processes, including flexographic printing, offset printing, and narrow-web printing.

Flexographic Printing

In flexographic printing, LED UV curing has become a game-changer. Flexo printing is widely used in packaging and label printing, where fast turnarounds and high-quality prints are crucial. With LED UV curing, flexo printers can achieve faster drying times, greater print quality, and improved durability, all while reducing the environmental impact.

Offset Printing

Offset printing, particularly in commercial and industrial printing, also benefits from LED UV curing. The system ensures quick curing of inks on a variety of substrates, which helps printers meet tight deadlines while maintaining the integrity and accuracy of the print. This makes LED UV curing an ideal choice for high-quality color prints, such as magazines, brochures, and packaging.

Narrow-Web Printing

Narrow-web printing, often used for labels, tags, and flexible packaging, requires precise and accurate printing due to the narrow substrate width. LED UV curing systems excel in narrow-web printing, providing instant curing and improved accuracy, ensuring that even the smallest details are sharp and well-defined.

Conclusion

LED UV curing systems represent a significant leap forward in the printing industry, offering numerous advantages over traditional curing methods. From faster print speeds to superior print quality and reduced environmental impact, these systems have become essential for modern printing operations. Whether in flexographic, offset, or narrow-web printing, LED UV curing continues to drive innovation, efficiency, and sustainability in the industry, positioning it as a vital component for future advancements in printing technology.