Ink adhesion refers to how well ink bonds to the substrate. This bond is critical for the final print’s durability and quality. Poor adhesion can lead to scuffing, peeling, or fading. This is unacceptable in many applications. Factors like surface energy of the substrate, ink chemistry, and the curing process all play a role. For narrow web printing, label printing, and flexographic applications, ensuring robust ink adhesion is paramount.

Traditional UV Curing vs. LED UV Curing

Historically, mercury vapor lamps were the standard for UV curing. These lamps emit a broad spectrum of UV light. While effective, they come with drawbacks. They generate considerable heat. This can warp heat-sensitive substrates. They also have a shorter lifespan and require frequent replacement. Furthermore, they consume more energy and produce ozone.

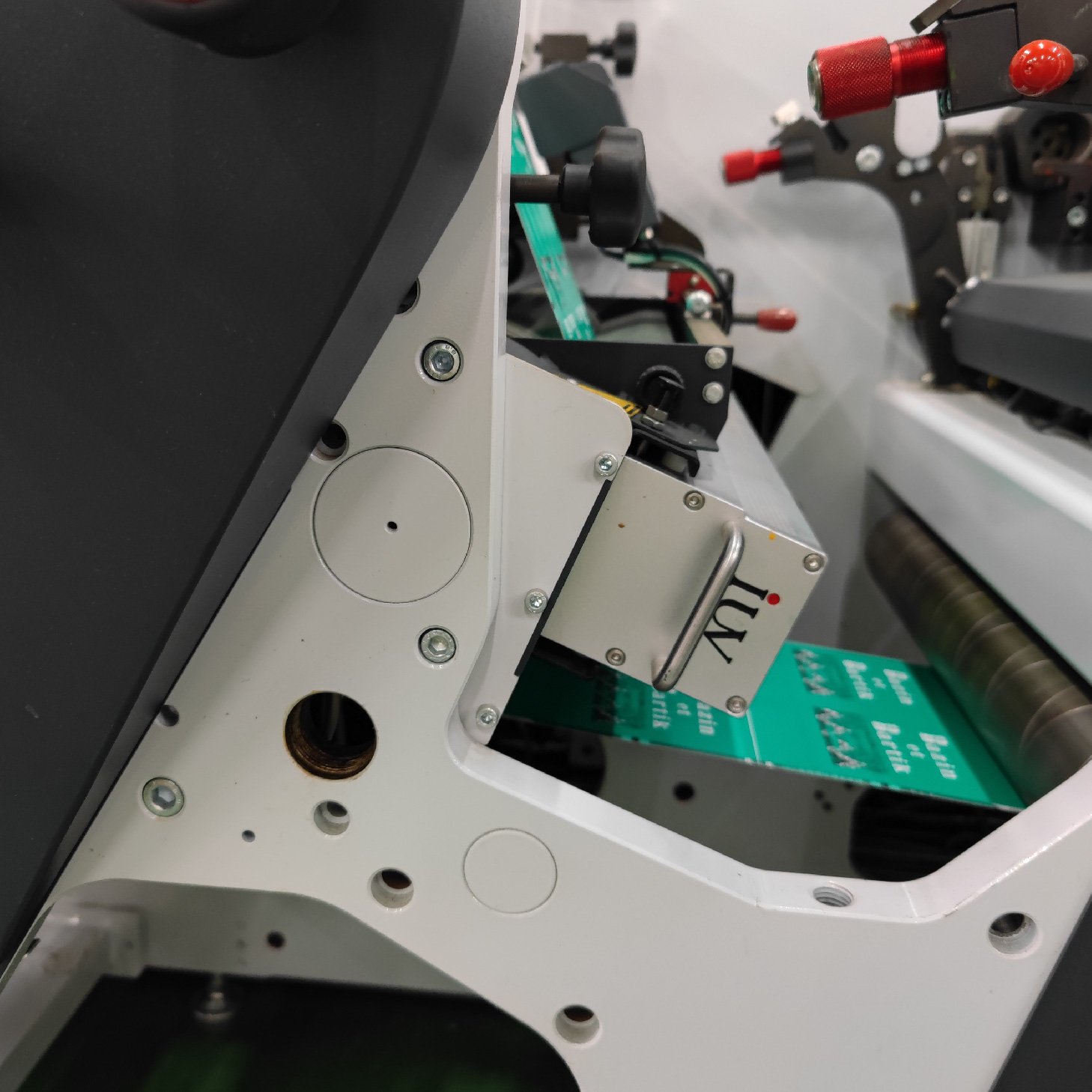

LED UV curing systems use light-emitting diodes. These diodes emit UV light at specific wavelengths. This targeted emission is a game-changer. It means less wasted energy. It also generates significantly less heat. This is a major benefit for printers working with delicate materials. The precise wavelength control also allows for more efficient curing of specific ink formulations.

The Science Behind LED UV Ink Adhesion

The effectiveness of LED UV curing hinges on the interaction between the UV light and the photoinitiators in the ink. When exposed to UV light of the correct wavelength, these photoinitiators generate free radicals. These radicals initiate a rapid polymerization process. This process transforms the liquid ink into a solid, cross-linked film.

LED UV systems excel here because they can precisely match their output wavelength to the absorption spectrum of the photoinitiators. This ensures a highly efficient and thorough cure. For a strong ink-to-substrate bond, complete polymerization is essential. Incomplete curing can leave uncured ink components. These can compromise the adhesion of the ink film to the material.

Impact on Different Substrates

The impact of LED UV curing on ink adhesion varies depending on the substrate. Each material presents unique challenges and benefits.

Plastics and Films: Many labels and packaging solutions use plastic films. These often have low surface energy. This makes it difficult for inks to adhere. Traditional curing methods might struggle to achieve a complete cure on these challenging surfaces. LED UV systems, with their efficient energy transfer, can promote better cross-linking. This results in improved adhesion on materials like PET, BOPP, and PVC. The lower heat output also prevents distortion of these thin films.

Paper and Cardboard: While generally easier to print on than plastics, paper and cardboard can still pose adhesion challenges. Absorbency plays a role. Inks need to cure properly on the surface rather than soaking in too deeply. LED UV curing ensures a fast surface cure. This locks the ink in place. It prevents it from migrating into the substrate. This maintains print quality and prevents smudging, especially important in narrow web and offset printing.

Metals and Foils: Printing on metal and foil substrates is common in specialty label and packaging. These materials are non-porous. Achieving strong adhesion requires an ink that can form a robust film. LED UV systems, by facilitating a complete and rapid cure, help create a durable ink layer that adheres well to these smooth surfaces. The controlled curing minimizes the risk of ink delamination.

Coated Stocks: Coated paper stocks offer a smooth printing surface. However, the coating itself can sometimes interfere with ink adhesion if not properly prepared or if the curing process is not optimal. LED UV curing provides a fast, high-energy cure that can overcome some of these challenges. It helps the ink form a strong bond to the coating and the underlying paper.

Benefits for Specific Printing Processes

Narrow Web and Label Printing: In this sector, speed and efficiency are crucial. LED UV curing systems offer instant drying. This allows for faster press speeds. It also enables immediate post-processing. For label printers, this translates to higher throughput. The consistent cure provided by LEDs ensures reliable ink adhesion on a wide range of label stocks. This is vital for product labels that undergo significant handling.

Flexographic Printing: Flexography is widely used for packaging and labels. The ability of LED UV to cure inks quickly and efficiently is a significant advantage. It allows for tighter registration. It also enables the use of finer screen rulings. Better ink adhesion means that complex graphics and fine text remain sharp and intact, even on flexible packaging materials.

Offset Printing (Sheet-fed and Web): While offset printing has traditionally used heatset or conventional drying, LED UV is making inroads. It offers energy savings and reduced heat. For offset printers, particularly those in the narrow web or specialty printing segments, LED UV can deliver excellent ink adhesion. This is especially beneficial for non-absorbent substrates.

Optimizing Ink Adhesion with LED UV

To maximize ink adhesion with LED UV systems, several factors should be considered:

- Ink Formulation: Use UV inks specifically designed for LED curing. These inks contain photoinitiators tuned to the wavelengths emitted by the LEDs.

- Substrate Preparation: Ensure the substrate has adequate surface energy for ink to adhere. Surface treatments may be necessary for very low-energy materials.

- Wavelength and Irradiance: Match the LED output wavelength to the ink’s photoinitiators. Ensure sufficient irradiance (light intensity) for effective curing.

- Dose: The total amount of UV energy delivered to the ink is critical. This is often referred to as “dose” and is a function of irradiance and exposure time.

- Press Settings: Optimize press speeds and ink laydown to allow for adequate UV exposure.

The Future of Printing with LED UV

LED UV curing systems represent a significant advancement in printing technology. Their ability to provide efficient, low-heat curing has a direct and positive impact on ink adhesion across diverse materials. From vibrant labels on plastic bottles to durable graphics on paper packaging, the reliable bond achieved with LED UV ensures the longevity and visual appeal of printed products. As the technology continues to mature, its adoption will likely grow. This will further drive innovation in ink formulations and printing processes. Printers investing in LED UV technology are positioning themselves for enhanced quality, efficiency, and sustainability in their operations.