LED Curing Systems: Redefining Ink Performance in Flexographic Printing

The flexographic printing industry is experiencing a significant shift. This transformation is driven by advancements in curing technology. Specifically, LED UV curing systems are at the forefront of this change. They are fundamentally altering how inks perform in flexographic printing. This is especially true for narrow web label printing.

Traditional UV curing methods have long been standard. They use mercury vapor lamps. These lamps emit a broad spectrum of UV light. While effective, they have limitations. Mercury lamps consume substantial energy. They also generate significant heat. This heat can affect the substrate. It can also impact the life of the printing plates. Furthermore, mercury lamps require frequent replacement. Disposal of these lamps also presents environmental concerns.

LED UV curing technology offers a compelling alternative. It utilizes light-emitting diodes. These diodes produce a narrow, specific wavelength of UV light. This precise wavelength is tailored to the photoinitiators in UV-curable inks. The result is highly efficient and rapid curing. This efficiency translates into several key benefits for flexographic printers.

One of the most immediate impacts is improved ink performance. LED curing excites photoinitiators more effectively. This leads to a more complete and robust cure. The ink film achieves superior hardness and scratch resistance. This is critical for labels that endure rough handling. Think of product labels on household cleaners or automotive fluids. These labels need to withstand abrasion. LED curing ensures the ink remains intact and vibrant.

Color reproduction also sees a notable enhancement. With traditional UV, excessive heat could cause ink to spread slightly. This can lead to a loss of fine detail and color saturation. LED systems generate very little heat. This preserves the integrity of the ink dot. It allows for sharper images and more brilliant colors. For brand owners, this means packaging that truly stands out on the shelf. Accurate color matching becomes easier and more consistent.

The speed of printing is another area where LED curing excels. Because LED lamps deliver precise wavelengths at high intensity, curing is almost instantaneous. This allows flexographic presses to run at higher speeds. Production throughput increases significantly. This directly impacts a printer’s ability to meet demanding delivery schedules. It also reduces the cost per label produced. In the competitive narrow web market, speed and efficiency are paramount.

Substrate versatility is also a major advantage. The low heat output of LED systems makes them suitable for a wider range of materials. Heat-sensitive substrates, like thin films or certain plastics, can now be reliably UV cured. This opens up new application possibilities for flexographic printers. Previously, printers might have been limited to paper or thicker plastics. Now, they can explore a broader spectrum of packaging solutions. This adaptability is invaluable in today’s diverse market.

Energy efficiency is a significant factor in operational costs. LED curing systems consume considerably less electricity than mercury lamps. They also have a much longer lifespan. This reduces both energy bills and lamp replacement expenses. The absence of mercury also simplifies disposal. This aligns with growing industry demands for sustainable printing practices. Printers are increasingly looking for ways to reduce their environmental footprint. LED UV curing is a key technology enabling this.

The ink formulation itself plays a crucial role. UV-curable inks contain photoinitiators. These molecules absorb UV light. This absorption triggers a chemical reaction. This reaction causes the ink to polymerize. It transforms from a liquid to a solid, cured film. Different ink chemistries are designed for specific printing processes and substrates. For flexographic printing, inks are formulated for good adhesion and flexibility.

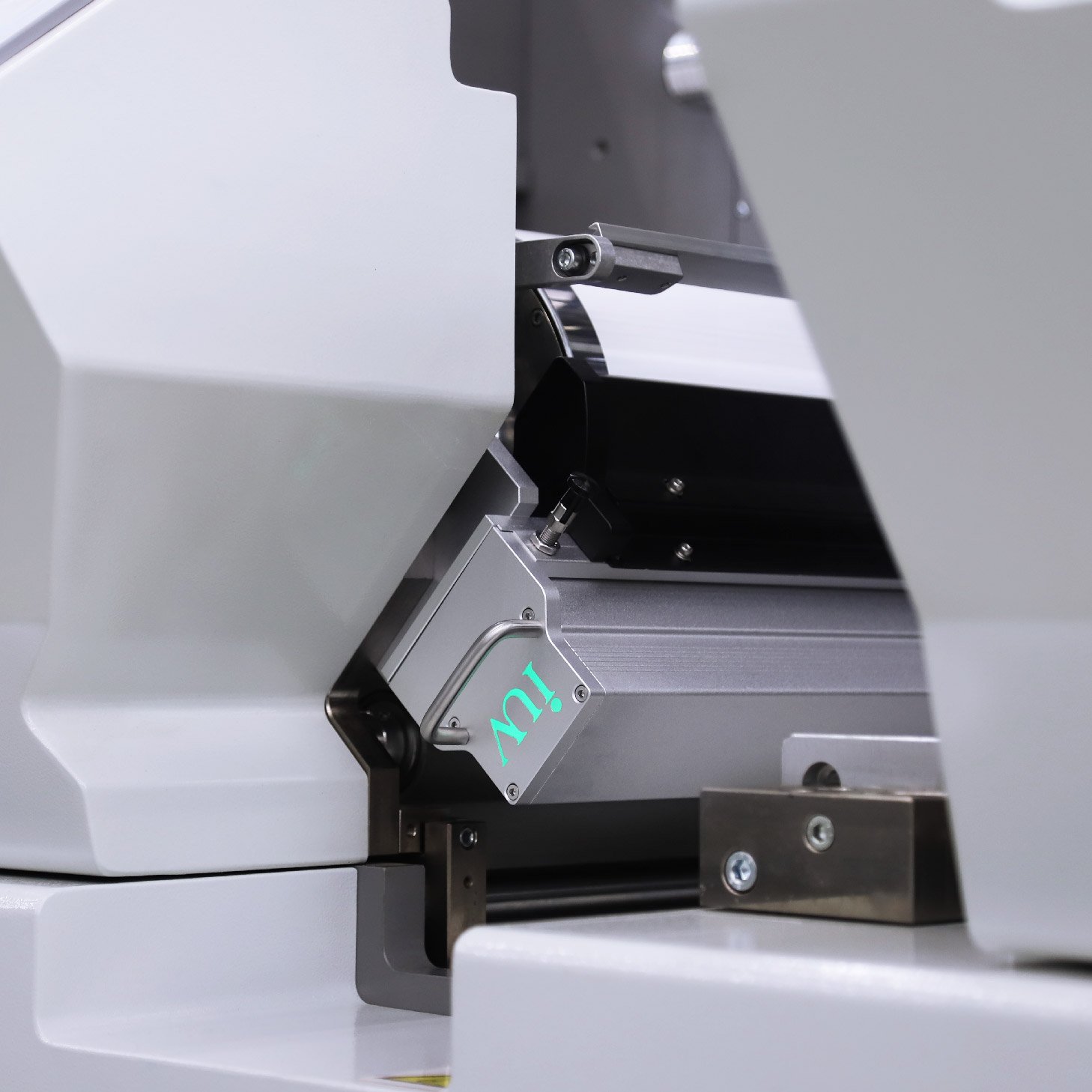

Narrow web flexographic printing is particularly well-suited for LED UV curing. This segment often involves high-volume production of labels and flexible packaging. The requirement for sharp detail, vibrant colors, and durable finishes is high. LED curing directly addresses these needs. It allows printers to achieve premium results consistently. The compact nature of LED heads also simplifies integration onto existing flexo presses. This makes upgrading to LED technology more accessible.

Offset printing, also known as sheetfed or commercial printing, has also benefited from UV curing. However, flexography, especially for labels, relies on flexible printing plates. These plates can be sensitive to heat. The low heat of LED curing is therefore a significant advantage. It helps extend the life of these valuable plates. This reduces tooling costs and downtime.

When discussing UV curing knowledge, it’s important to understand the spectrum. Mercury lamps emit UV-A, UV-B, and UV-C. They also produce visible light and heat. LED systems can be precisely tuned. They typically emit in the UV-A range, around 365 nm, 395 nm, or other specific wavelengths. This targeted emission ensures maximum energy transfer to the photoinitiators. This leads to faster, more efficient curing.

The print quality achievable with LED UV flexography is exceptional. Fine lines, halftones, and solid areas are rendered with remarkable clarity. The ink transfer in flexo printing is controlled by the anilox roll. LED curing ensures that the ink transfer remains consistent and precise. It prevents premature drying or skinning of the ink on the anilox. This contributes to a smoother printing process and higher quality output.

For printers looking to enhance their flexographic capabilities, especially in the narrow web label sector, investing in LED UV curing systems is a strategic move. It offers a pathway to improved ink performance, faster production speeds, greater substrate versatility, and reduced operational costs. The technology redefines what is possible in terms of ink durability and visual appeal. It positions printers to meet the evolving demands of brand owners. It ensures their labels and packaging are not only functional but also visually striking and sustainable. The future of flexographic printing is undoubtedly illuminated by LED technology.