LED Curing Systems: Cutting Edge Technology for Faster and More Efficient Printing

In the dynamic world of printing, staying ahead means embracing innovation. For years, the industry relied on traditional UV curing methods. These systems used mercury lamps. They generated significant heat and consumed a lot of energy. Now, a new era has dawned with LED curing systems. This cutting-edge technology is revolutionizing how we print. It offers remarkable benefits in speed, efficiency, and sustainability.

The shift to LED UV curing is a game-changer for label printing. Labels demand vibrant colors and sharp details. They often require quick turnaround times. Traditional methods struggle to keep up. LED curing provides instant, pinpointed energy. This translates to faster print speeds. It also means sharper dot reproduction. This is critical for high-quality label graphics. The consistency of LED curing ensures every label meets high standards. This reduces waste and improves overall production.

Flexographic printing, or flexo, is another area seeing immense transformation. Flexo is widely used for packaging and labels. It relies on flexible printing plates. These plates transfer ink to the substrate. In the past, heat from mercury lamps could warp these plates. This led to print quality issues. LED UV curing emits very little heat. This protects the delicate flexo plates. It maintains their integrity for longer. The result is consistent print quality across long runs. Faster curing also means faster press speeds. This directly impacts production output and profitability.

Offset printing, also known as lithography, is known for its precision. It is often used for commercial printing and high-end packaging. While offset traditionally uses heatset or UV curing, LED technology is making inroads. The lower heat output of LED systems is gentle on a wider range of substrates. This includes heat-sensitive materials. This expands the possibilities for offset printers. They can achieve vibrant, durable prints. They can do so with greater energy efficiency. The instant on/off capability of LEDs also reduces energy consumption. This is especially beneficial for job shops with varied print runs.

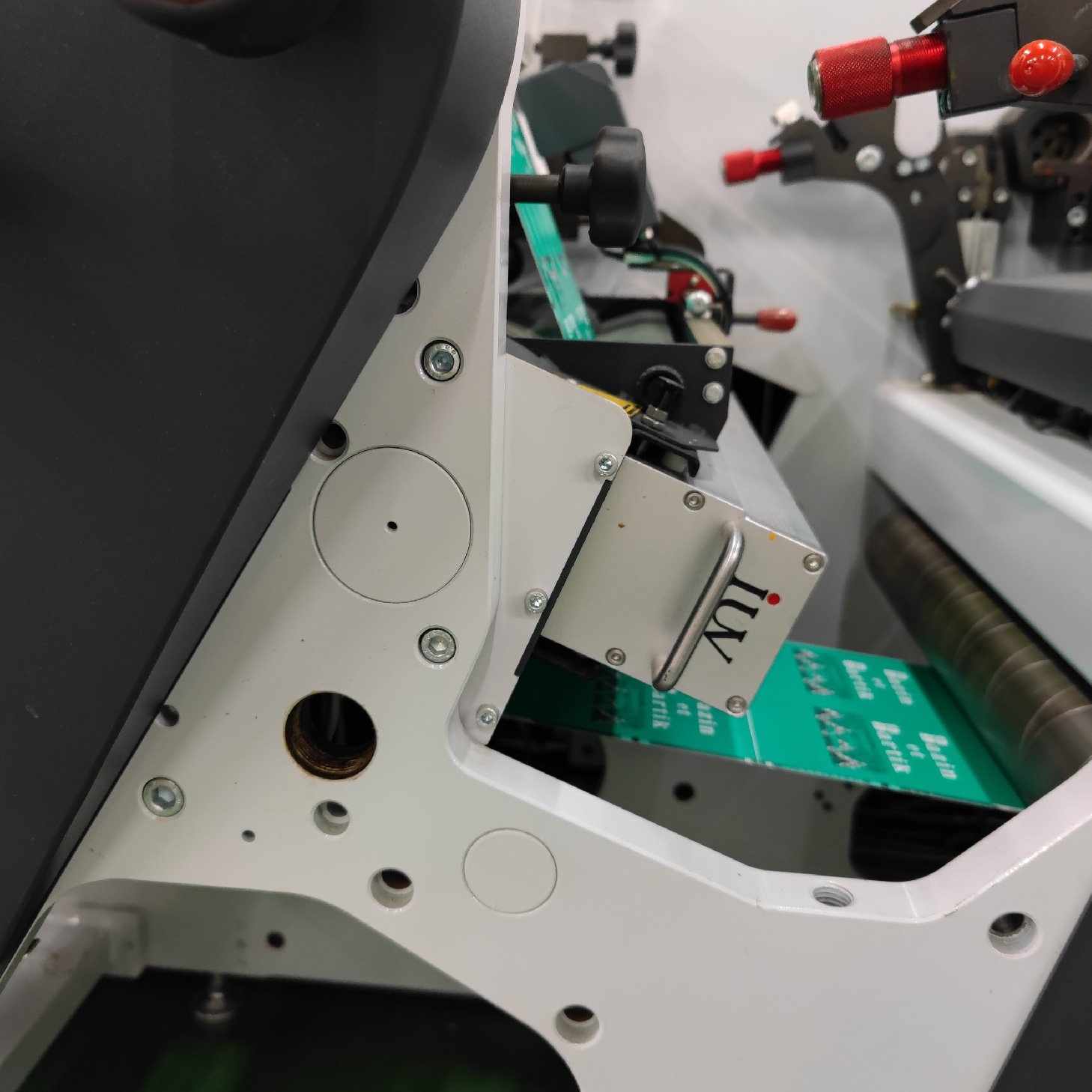

Narrow web printing, a specialty within label and flexible packaging, benefits enormously. Narrow web presses operate at high speeds. They require precise ink control. LED curing integrates seamlessly into these demanding environments. The compact size of LED modules allows for flexible integration. They fit easily into existing narrow web press designs. The precise wavelength control of LEDs ensures optimal ink curing. This leads to excellent adhesion and rub resistance. Printers can achieve brilliant finishes. They can do this without compromising speed. The reduced energy footprint also aligns with sustainability goals. This is increasingly important for brand owners.

Understanding UV curing is key to appreciating LED technology. UV curing uses ultraviolet light. This light initiates a photochemical reaction. This reaction hardens liquid inks and coatings. It transforms them into a solid, durable layer. Traditional mercury lamps emit UV light across a broad spectrum. This includes unwanted heat and infrared radiation. LED curing systems use light-emitting diodes. These diodes emit UV light at specific, narrow wavelengths. This targeted energy is highly efficient. It cures ink and coatings faster. It does so with less wasted energy.

The energy efficiency of LED curing is a significant advantage. Mercury lamps are energy hogs. They require warm-up and cool-down periods. They also generate considerable heat. This often necessitates additional cooling systems. LED systems consume far less power. They reach full curing power almost instantly. They also produce minimal heat. This reduces the overall energy bill. It also lowers the environmental impact of the printing process. This is a win for both the printer and the planet.

Durability and performance are paramount in printed products. LED UV curing ensures inks and coatings are robust. They offer excellent scratch and abrasion resistance. They also provide superior chemical resistance. This is vital for labels exposed to harsh environments. It is also important for packaging that undergoes rough handling. The precise curing process ensures complete cross-linking of the ink polymers. This results in a tougher, more resilient finish.

Beyond technical benefits, LED curing offers operational advantages. The long lifespan of LED lamps is remarkable. They can last tens of thousands of hours. This is significantly longer than mercury lamps. This reduces maintenance costs and downtime. It also eliminates the need for frequent lamp replacements. The plug-and-play nature of many LED systems simplifies installation. They are often easier to integrate into existing workflows. This smooth transition minimizes disruption.

The versatility of LED curing systems is another strong point. They can be used with a wide range of substrates. This includes plastics, films, and paper. They work with various ink and coating formulations. The ability to fine-tune the wavelength output of LEDs allows for optimization. This ensures the best results for specific materials and chemistries. This adaptability makes them a valuable investment. They can handle diverse printing projects.

The future of printing is undoubtedly linked to sustainable practices. LED curing systems are at the forefront of this movement. Their reduced energy consumption means a smaller carbon footprint. The lower heat output minimizes the need for cooling. This further conserves energy. The longer lifespan of LED lamps reduces waste. It also decreases the hazardous waste associated with replacing mercury lamps.

For printers looking to enhance productivity and profitability, LED curing systems offer a clear path. They deliver faster speeds, superior print quality, and greater operational efficiency. They also contribute to a more sustainable printing operation. Embracing this cutting-edge technology is not just an upgrade; it’s a strategic move towards future-proofing your business in the competitive print landscape. The advantages in label, flexo, offset, and narrow web printing are undeniable. Investing in LED curing is investing in a brighter, more efficient printing future.