The label printing industry is in constant evolution. Demands for faster turnaround times, higher quality, and greater efficiency are driving innovation. Digital printing technologies have made significant strides. However, to truly maximize output and capitalize on their potential, integrating advanced automation is key. One of the most impactful areas for this automation is in the curing process, specifically with LED UV technology.

The Promise of LED UV Curing in Label Printing

Traditional curing methods, such as mercury vapor lamps, have long been the standard. However, they come with several drawbacks. They generate substantial heat, require significant warm-up and cool-down times, and their energy consumption is high. Furthermore, mercury lamps have a shorter lifespan and contain hazardous materials.

LED UV curing offers a compelling alternative. These systems utilize light-emitting diodes to produce UV light. The advantages are numerous and directly address the needs of high-volume label printing. LED systems offer instant on/off capabilities, meaning no warm-up is needed. This directly translates to reduced downtime between jobs. Their energy efficiency is remarkable, consuming considerably less power than mercury lamps. This not only lowers operational costs but also contributes to a more sustainable printing process.

Moreover, LED UV lamps emit a narrower spectrum of UV light, which can be precisely matched to the specific ink formulations. This targeted approach leads to more efficient curing and can often result in improved print quality and durability. The long lifespan of LED lamps also reduces maintenance and replacement costs, further enhancing overall cost-effectiveness.

Automation: The Missing Link for Enhanced Output

While LED UV technology itself offers significant benefits, its true power in label printing is unlocked through automation. When integrated seamlessly into the digital press workflow, LED UV curing systems become an indispensable component for achieving maximum output. Automation in this context goes beyond simply turning the lamps on and off. It involves intelligent control systems that optimize curing parameters based on press speed, ink density, and substrate type.

Consider the challenges of variable data printing or short-run jobs that are the hallmark of digital label printing. Each new job might require different ink formulations or printing speeds. Manual adjustments to the UV curing system can be time-consuming and prone to error. An automated system, however, can receive job parameters directly from the digital press’s workflow management software. This allows for real-time adjustments to UV intensity, exposure time, and even the specific wavelengths of light used.

Streamlining the Printing Process with Integrated Systems

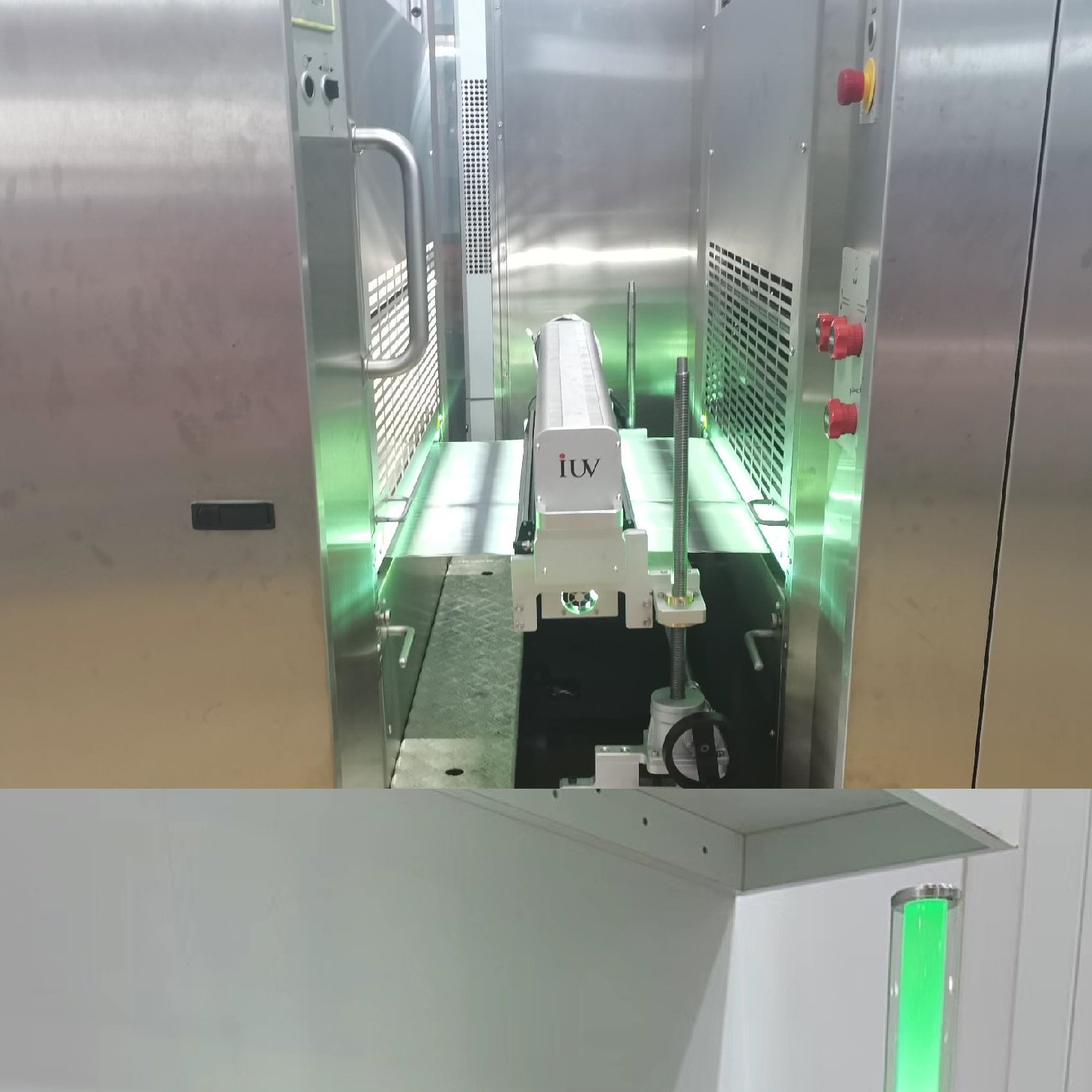

The integration of LED UV automation means that the curing process is no longer a separate, manual step. Instead, it becomes an integral part of the printing sequence. As the substrate exits the print heads, it immediately passes under the precisely controlled LED UV array. This ensures that each printed area is cured effectively and consistently, regardless of the press speed.

This seamless integration is particularly crucial in narrow-web label printing. Presses in this sector operate at high speeds, often reaching hundreds of meters per minute. Any bottleneck in the curing process can significantly limit the overall throughput. Automated LED UV systems are designed to keep pace with these high speeds, ensuring that curing is never the limiting factor.

Benefits Across Different Printing Technologies

While the focus is often on digital label presses, the principles of LED UV automation extend to other label printing methods as well. In flexographic printing, for instance, LED UV curing can dramatically reduce the time required for inter-deck curing. This allows for faster printing speeds and the ability to print with a wider range of inks, including highly opaque whites or vibrant spot colors, without the risk of ink transfer or smudging.

For offset or sheetfed label printing, although less common for short runs, LED UV integration can also offer advantages. It allows for faster stacking of printed sheets, immediate finishing operations, and reduces the need for special coatings to prevent blocking. However, it is in the realm of narrow-web digital label printing where LED UV automation truly shines and delivers its most profound impact on output.

Optimizing Curing Parameters for Diverse Applications

The “maximum output” goal is not just about speed; it’s also about versatility and quality. Different label applications require different performance characteristics. For example, a label for a food product might need excellent resistance to abrasion and chemicals. A label for an outdoor application might require enhanced weatherability and fade resistance.

Automated LED UV systems, when coupled with advanced ink formulations designed for LED curing, allow printers to fine-tune the curing process to achieve these specific properties. By adjusting the UV dose—the combination of intensity and exposure time—printers can ensure complete polymerization of the ink, leading to optimal adhesion, hardness, and resistance properties. This level of control is difficult to achieve with older, less precise curing technologies.

Addressing Substrate Challenges with Precision

Label printing involves a wide array of substrates, from glossy papers and films to textured and opaque materials. Each substrate interacts differently with heat and UV light. Traditional curing methods, with their high heat output, could sometimes damage heat-sensitive substrates, leading to warping or delamination.

LED UV curing generates very little heat, making it ideal for a broad range of substrates. The focused nature of LED light also means that only the ink is exposed to the UV energy, minimizing any potential impact on the substrate itself. An automated system can further enhance this by adjusting UV intensity to prevent over-curing or under-curing on different materials, ensuring consistent results across a diverse print environment.

The Role of Ventilation and Heat Management

While LED UV systems are inherently cooler than mercury lamps, proper ventilation remains an important consideration, especially in high-speed, continuous printing environments. Automated systems can be integrated with press control systems to manage airflow and exhaust. This ensures that any residual heat generated is effectively removed, maintaining optimal operating temperatures for both the curing system and the press itself. This proactive heat management contributes to the longevity of the equipment and the stability of the printing process, both vital for sustained high output.

Future Trends and Considerations

The ongoing development in LED UV technology, particularly in areas like improved spectral output and higher energy efficiency, will continue to push the boundaries of what’s possible in label printing. As digital presses become even faster and more sophisticated, the demand for equally advanced curing solutions will only grow. The trend towards smarter, more connected printing environments means that the integration of LED UV automation will become even more seamless. Systems will communicate more effectively, leading to greater predictive maintenance capabilities and even more precise, real-time process control.

For label printers looking to stay competitive, embracing LED UV curing automation is not just an upgrade; it’s a strategic necessity. It’s the pathway to unlocking the full potential of digital printing technology, enabling faster speeds, superior quality, greater substrate versatility, and ultimately, maximum output. The investment in this technology will pay dividends in efficiency, cost savings, and the ability to meet the evolving demands of the market.