With the advent of Industry 4.0, intelligence, automation and dataization have become the main trends of industrial development, and UV curing technology has also undergone profound changes in this context. IUV , as a leader in UV curing systems, has continuously innovated and upgraded its technology, improve the performance of the system, and also allow customers to gain more convenience and benefits in production efficiency, equipment management, maintenance, etc.

Intelligent Control System

1.1 Intelligent adjustment and adaptive control

IUV’s system adopts dynamic power allocation technology to automatically adjust the system power output according to production needs and curing requirements.

At different production stages, the system can adjust power consumption according to real-time load to improve overall production efficiency.

- Energy saving optimization

- Intelligent scheduling

1.2 Fault warning and self-diagnosis system

The system can automatically detect equipment data in real time, diagnose common problems and provide real-time solutions, greatly reducing downtime and improving production efficiency.

- Real-time data monitoring

- Remote operation

- Automatic diagnosis

Data and cloud integration

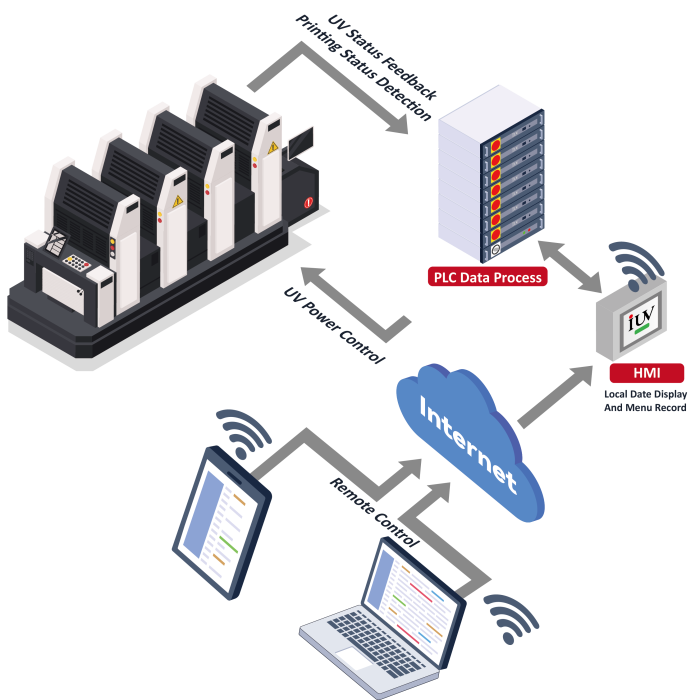

2.1 Intelligent production line connection

IUV’s UV curing system can be seamlessly connected to the entire production line, and cooperate with the PLC system to achieve real-time data transmission and production scheduling. All links in the production line can share data in real time, and each step of the production process can be accurately monitored and optimized.

- Data sharing

- Automatic scheduling

2.2 Cloud control and remote operation

IUV’s UV curing system supports remote software upgrades and technical support, and customers can obtain the latest functions and performance optimizations without going to the site. This remote technical support method effectively improves the maintenance efficiency of the system and reduces operating costs.

- Software update

- Online technical support

High efficiency and green environmental protection

3.1 Energy-saving optimization algorithm

IUV’s UV curing system adopts advanced energy-saving optimization algorithms. According to production needs, the system can intelligently determine the optimal energy efficiency mode, reduce ineffective energy consumption, and reduce operating costs.

- Automatic power adjustment

- Standby mode

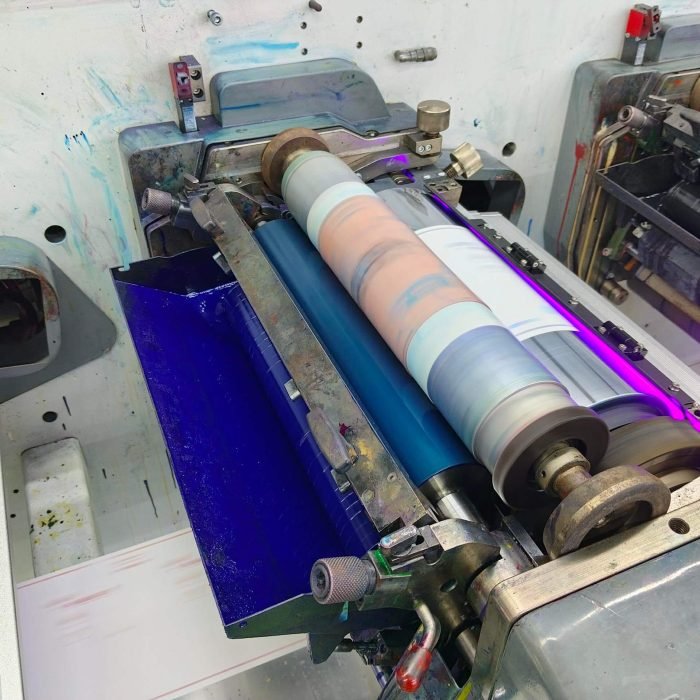

3.2 Efficient cooling and thermal management

IUV’s UV curing system optimizes the thermal management system by improving cooling technology, reducing the temperature of the equipment, and improving the service life and stability of the UV system.

- Intelligent temperature control

- Environmentally friendly

User experience and interface upgrade

Industry 4.0 not only improves the intelligence level of equipment, but also focuses on the optimization of user experience. IUV’s UV curing system has made many improvements in the operation interface and user interaction, making the operation more intuitive and simple.

4.1 Intelligent touch interface

IUV’s UV curing system is equipped with an intelligent touch interface, supports multi-language switching, and is more user-friendly.

- Real-time status display

- Customized operation

4.2 Improved ease of operation

By optimizing hardware and software design, the operation process of IUV’s UV curing system is more simplified and manual intervention is reduced.

- Data visualization

- Predictive maintenance

With the continuous advancement of technology, IUV will continue to drive innovation in the field of intelligent manufacturing and provide strong support for industrial upgrading.