In the competitive world of narrow-web printing, achieving precise registration is paramount. Consumers expect vibrant colors and sharp details on labels and flexible packaging, and anything less can significantly impact brand perception and product appeal. Registration refers to the accurate alignment of different ink colors or printing stations on the substrate. Even minor misalignments, often referred to as “registration errors,” can render a print run unacceptable, leading to costly waste and production delays. For narrow-web presses, where substrate widths are limited and print runs can be short, efficiency and accuracy are especially critical.

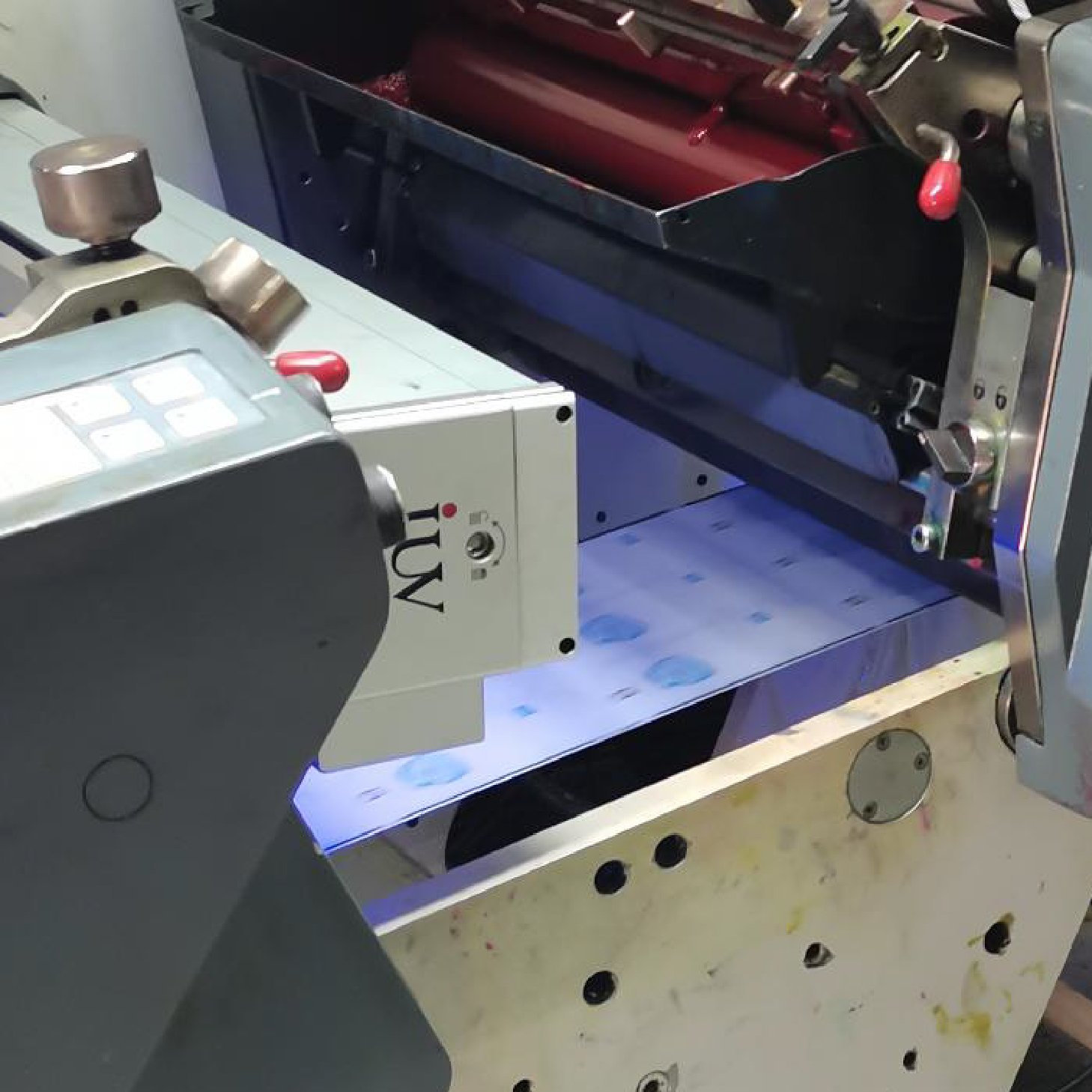

One of the most impactful technological advancements addressing this challenge is the integration of automated UV drying systems, particularly LED UV curing technology. This technology offers a transformative approach to managing ink properties and substrate behavior during the printing process, directly contributing to improved registration accuracy.

Understanding the Challenges of Registration in Narrow-Web Printing

Several factors can contribute to registration issues on narrow-web presses:

- Substrate Stretch and Shrinkage: Paper, film, and foil substrates are susceptible to changes in dimension due to environmental factors like humidity and temperature, or even the mechanical forces applied during printing. Variations in these dimensions between different printing stations can lead to color misregistration.

- Ink Transfer and Drying: The way ink is transferred to the substrate and how it dries play a crucial role. If ink doesn’t dry uniformly or quickly enough, it can smear, offset onto adjacent surfaces, or cause the substrate to ripple or distort, all of which disrupt accurate color placement.

- Press Speed and Dynamics: Narrow-web presses often operate at high speeds. The dynamic forces involved in web movement, roller pressure, and ink application can amplify minor inconsistencies, leading to registration drift.

- Operator Intervention: Manual adjustments are often required to correct registration. However, these adjustments can be time-consuming and may introduce new errors if not performed precisely.

The Science Behind UV Curing and its Impact on Registration

UV curing technology utilizes ultraviolet light to initiate a photochemical reaction that instantly solidifies (cures) ink, coatings, and adhesives. This process is fundamentally different from traditional drying methods, which rely on solvent evaporation.

Traditional Solvent-Based Drying: This method involves solvents within the ink that evaporate as the substrate passes through a drying tunnel. This evaporation process can take time, and as solvents leave the ink, they can cause changes in the ink film and potentially affect the substrate itself, leading to expansion or contraction. Inconsistent drying across the web width or between stations can create registration problems.

UV Curing Technology: UV inks contain photoinitiators and monomers/oligomers. When exposed to UV light of specific wavelengths, the photoinitiators absorb the energy and start a polymerization process. This rapid cross-linking of molecules creates a solid, durable film almost instantaneously.

How Automated UV Drying Enhances Registration Accuracy

The benefits of automated UV drying, especially LED UV, for registration accuracy are multifaceted:

1. Instant Ink Solidification and Reduced Substrate Movement

UV inks cure upon exposure to UV light. This means that immediately after ink is applied to the substrate, it solidifies. This rapid solidification minimizes the time the ink film is in a wet state, significantly reducing the potential for:

- Ink Smearing and Offsetting: Wet ink can easily transfer to other parts of the press or the backside of the substrate. Instant curing prevents this, ensuring ink stays precisely where it was printed.

- Substrate Distortion: The evaporation of solvents in traditional drying can cause the substrate to swell or shrink. UV curing avoids this, maintaining the substrate’s dimensions and thus preserving the accuracy of previously printed elements. This is particularly vital in multi-color printing processes like flexography and offset.

2. Consistent Ink Film Properties

UV inks, once cured, form a highly stable and uniform film. This consistency is crucial for achieving predictable color reproduction and accurate registration. Unlike solvent inks, which can experience variations in drying rate and film thickness, UV-cured inks offer a predictable performance profile. This consistency translates to:

- Predictable Ink Transfer: Operators can rely on the ink behaving consistently from one print to the next, reducing the need for frequent registration adjustments.

- Uniform Color Density: Consistent ink films ensure that color density is uniform across the print, contributing to overall visual appeal and accurate registration of adjacent color layers.

3. Controlled Curing Conditions

Automated UV drying systems, especially modern LED UV units, offer precise control over the curing process. Parameters such as UV intensity and exposure time can be fine-tuned for different inks and substrates. This level of control allows printers to:

- Optimize Curing for Specific Materials: Different substrates (e.g., thin films versus thick paper) and inks (e.g., opaque whites versus transparent colors) require specific curing conditions. Automated systems allow for precise adjustments, ensuring optimal ink solidification without damaging heat-sensitive substrates.

- Maintain Consistent Performance Across Runs: Once optimal settings are determined, they can be saved and recalled for future jobs, ensuring consistent results and minimizing operator error. This is a significant advantage in short-run, high-mix environments common in narrow-web printing.

4. Reduced Heat Generation

While traditional UV lamps can generate significant heat, LED UV curing is a much cooler process. This is a critical advantage for narrow-web printing on heat-sensitive substrates like thin films. Excessive heat can cause:

- Substrate Warping and Shrinkage: High temperatures can lead to dimensional instability in the substrate, directly impacting registration.

- Ink Degredation: Overheating can sometimes affect the properties of the ink itself, altering its color or adhesion.

The cooler operation of LED UV systems helps maintain substrate integrity and ensures that the ink properties remain stable throughout the curing process, thus preserving registration accuracy.

LED UV: The Future of Automated Drying for Narrow-Web Presses

LED UV technology represents the latest generation of UV curing. Compared to traditional mercury vapor UV lamps, LED UV offers several advantages that are particularly beneficial for narrow-web printing and registration:

- Instant On/Off Capability: LEDs turn on and off instantly, which is energy-efficient and allows for precise control over curing at specific points on the press. This is in contrast to mercury lamps which require warm-up and cool-down periods.

- Longer Lifespan: LEDs have a significantly longer operational lifespan than mercury lamps, reducing maintenance costs and downtime.

- Lower Heat Output: As mentioned, LEDs generate considerably less heat, making them ideal for heat-sensitive substrates.

- Wavelength Specificity: LEDs emit light within a narrow wavelength band, which can be matched precisely to the photoinitiators in the ink. This leads to more efficient curing and a more robust ink film.

- Compact Footprint: LED UV systems are often more compact, which is a valuable consideration on space-constrained narrow-web presses.

Practical Applications in Flexography and Offset Narrow-Web Printing

Both flexographic and offset printing are widely used in the narrow-web sector. Automated UV drying, especially LED UV, offers significant improvements for registration in both:

Flexography: In flexo, the design is raised on a flexible plate. Precise ink transfer and immediate drying are crucial for sharp dot reproduction and accurate color overlay. UV-cured inks, with their fast drying, minimize dot gain and prevent ink spread, allowing for better definition and registration between colors. The control offered by automated UV systems ensures that the substrate doesn’t stretch or shrink between stations, maintaining perfect alignment of each color.

Offset Lithography: Narrow-web offset presses also benefit immensely. In offset, water and ink are transferred to the printing plate, then to a blanket cylinder, and finally to the substrate. The interaction between ink and water, coupled with the printing pressures, can be challenging for registration. UV inks cure instantly on the substrate, preventing any interaction or smearing with subsequent ink or water applications, thereby securing the integrity of each printed element and improving overall registration.

Conclusion: A Strategic Investment for Precision Printing

Achieving and maintaining superior registration accuracy on narrow-web presses is no longer a matter of chance; it’s a result of smart technological integration. Automated UV drying systems, particularly those employing LED UV technology, provide printers with the control and precision needed to overcome common registration challenges.

By enabling instant ink solidification, reducing substrate movement, ensuring consistent ink film properties, and operating with minimal heat, these systems directly enhance registration accuracy. This leads to fewer print defects, reduced waste, higher productivity, and ultimately, the ability to deliver the high-quality labels and packaging that modern brands demand. For narrow-web printers looking to elevate their print quality and operational efficiency, investing in automated UV drying is a strategic decision that yields tangible results.