Achieving pinpoint registration is a cornerstone of high-quality flexographic printing, particularly in the demanding label and narrow web sectors. Any deviation, however slight, can compromise brand integrity and lead to costly reprints. The advent and widespread adoption of LED UV curing technology have offered printers new avenues to enhance not only speed and efficiency but also the very precision of their print process. This article explores how optimizing LED UV curing parameters can directly lead to improved registration accuracy in flexo printing.

The Challenge of Registration in Flexo Printing

Flexographic printing, with its inherent flexibility and ability to print on diverse substrates, faces unique registration challenges. The flexible nature of the printing plates, combined with the pressures involved in the printing nip, can lead to plate deformation or “squish.” Furthermore, web tension variations, environmental factors like humidity and temperature, and the mechanical precision of the press itself all play a role.

In narrow web printing, where jobs often demand tight tolerances and intricate designs for labels and packaging, even minor misregistration is quickly apparent. This is especially true when multiple colors need to perfectly align to create a seamless image or legible text. Traditional methods of achieving registration involve meticulous setup, precise tension control, and often, slower press speeds to allow for mechanical settling.

Understanding LED UV Curing and its Impact

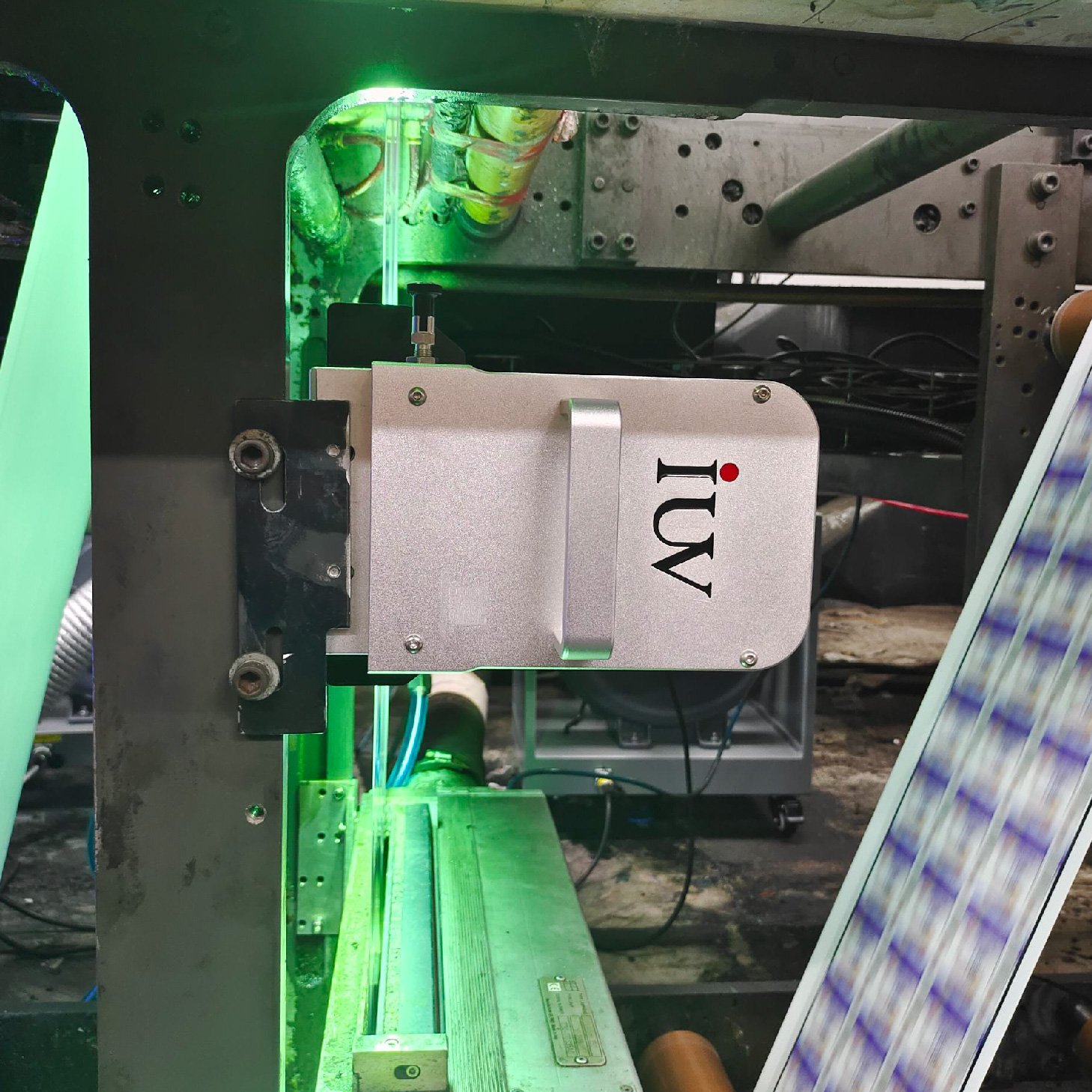

LED UV curing systems utilize Light Emitting Diodes to emit ultraviolet light. Unlike traditional mercury vapor lamps, LED systems offer several advantages. They provide a more focused and consistent spectrum of UV light, generate less heat, and have a longer operational lifespan. This reduction in heat is particularly significant for registration.

Traditional UV lamps, especially mercury vapor lamps, can generate substantial heat. This heat can cause the substrate to expand, leading to dimensional instability. As the web moves through the press, this expansion and contraction can shift the printed image, making it difficult to maintain accurate registration, especially across long print runs.

LED UV curing, by contrast, emits significantly less heat onto the substrate. This “cooler” curing process minimizes substrate expansion and contraction. When the substrate remains more dimensionally stable, the printed dots and lines are less likely to shift out of position relative to each other. This inherent benefit of LED technology provides a foundation for improved registration accuracy from the outset.

Optimizing LED UV Curing for Registration

While the reduced heat output of LED UV is a significant advantage, simply installing an LED system doesn’t automatically guarantee perfect registration. Printers must actively optimize the curing process to leverage its full potential.

1. Wavelength and Irradiance Control: LED systems offer precise control over the emitted wavelength and irradiance (the power density of the UV light). Different UV curable inks and coatings are formulated to cure optimally at specific wavelengths. Ensuring the LED system’s output matches the ink’s requirements is critical. If the UV light is not sufficiently potent or is at the wrong wavelength, partial curing can occur. This can lead to ink film instability, which in turn can affect dot gain and fine detail reproduction, indirectly impacting perceived registration.

2. Curing Speed and Dwell Time: The speed at which the web travels through the press directly correlates with the “dwell time” the ink has under the UV lamps. With LED UV, printers can often run at higher speeds without compromising cure. However, it’s crucial to balance speed with adequate dwell time to ensure complete and thorough curing. Insufficient cure can result in ink transfer issues or smudging, which are often mistaken for registration problems. Conversely, over-curing is generally not an issue with LEDs, but it’s always best to follow ink manufacturer recommendations.

3. Lamp Placement and Intensity Uniformity: The placement of the LED UV lamps relative to the printing stations is paramount. Lamps should be positioned to effectively cure the ink immediately after the printing nip, or at specific points in the press where stability is highest. Furthermore, ensuring uniform intensity across the width of the web is essential. Hot spots or uneven curing can lead to localized ink film properties, potentially affecting registration. Modern LED systems are designed for excellent uniformity, but regular checks and maintenance are still advised.

The Interplay with Other Press Variables

Improving registration accuracy with LED UV curing is not a solitary pursuit. It works in conjunction with other critical press parameters:

1. Web Tension Control: Consistent and accurate web tension is arguably the most crucial factor for maintaining registration. LED UV’s reduced heat helps minimize tension fluctuations caused by substrate expansion. However, robust tension control systems are still vital. When the substrate is dimensionally stable due to cooler curing, the tension control system has a more predictable and stable environment to work within, leading to more consistent placement of each printed impression.

2. Plate and Anilox Roll Selection: The quality and condition of flexo plates and anilox rolls directly influence ink transfer. High-quality, precisely engraved anilox rolls and accurately manufactured plates are fundamental. With LED UV, the consistent and efficient cure can help “lock down” the ink film more effectively onto the substrate, preserving the fine details transferred from the anilox and plate. This preserves the sharpness of dots and lines, making alignment easier.

3. Ink Formulation: The choice of UV curable inks is critical. High-performance inks designed for flexo printing and LED curing offer excellent adhesion, color strength, and cure speed. Modern LED UV inks are formulated to cure rapidly and efficiently under specific LED wavelengths, ensuring a stable ink film that is less prone to smearing or smudging, which can compromise registration.

Practical Applications and Benefits

For label printers, the benefits are immediate. Complex multi-color labels with fine text and intricate graphics can be produced with greater consistency. This reduces the need for frequent adjustments and minimizes waste. The ability to run at higher speeds, made possible by efficient LED curing, translates directly into increased throughput and profitability.

In the flexible packaging sector, where precise registration is often required for intricate designs and barcode readability, LED UV offers a significant advantage. The consistent curing ensures that the ink film is robust and stable, contributing to the overall print quality and functional requirements of the packaging.

Conclusion

Improving registration accuracy in flexo printing with LED UV curing is achieved through a holistic approach. While the inherent benefits of cooler, more controlled curing from LED technology provide a strong foundation, printers must actively optimize their LED systems. This includes ensuring correct wavelength, irradiance, and dwell times, alongside maintaining excellent control over web tension, utilizing high-quality printing elements, and selecting appropriate ink formulations. By understanding and harnessing these interdependencies, flexo printers can unlock new levels of precision and efficiency, delivering superior quality and meeting the ever-increasing demands of the market.