Flexographic printing, especially in the narrow web sector for labels, faces constant pressure to reduce costs. Ink waste is a significant contributor to these expenses. Traditional drying methods often lead to excessive ink usage and material waste. However, the advent of UV curing systems has revolutionized this. These systems offer a powerful solution to minimize ink waste and boost overall efficiency.

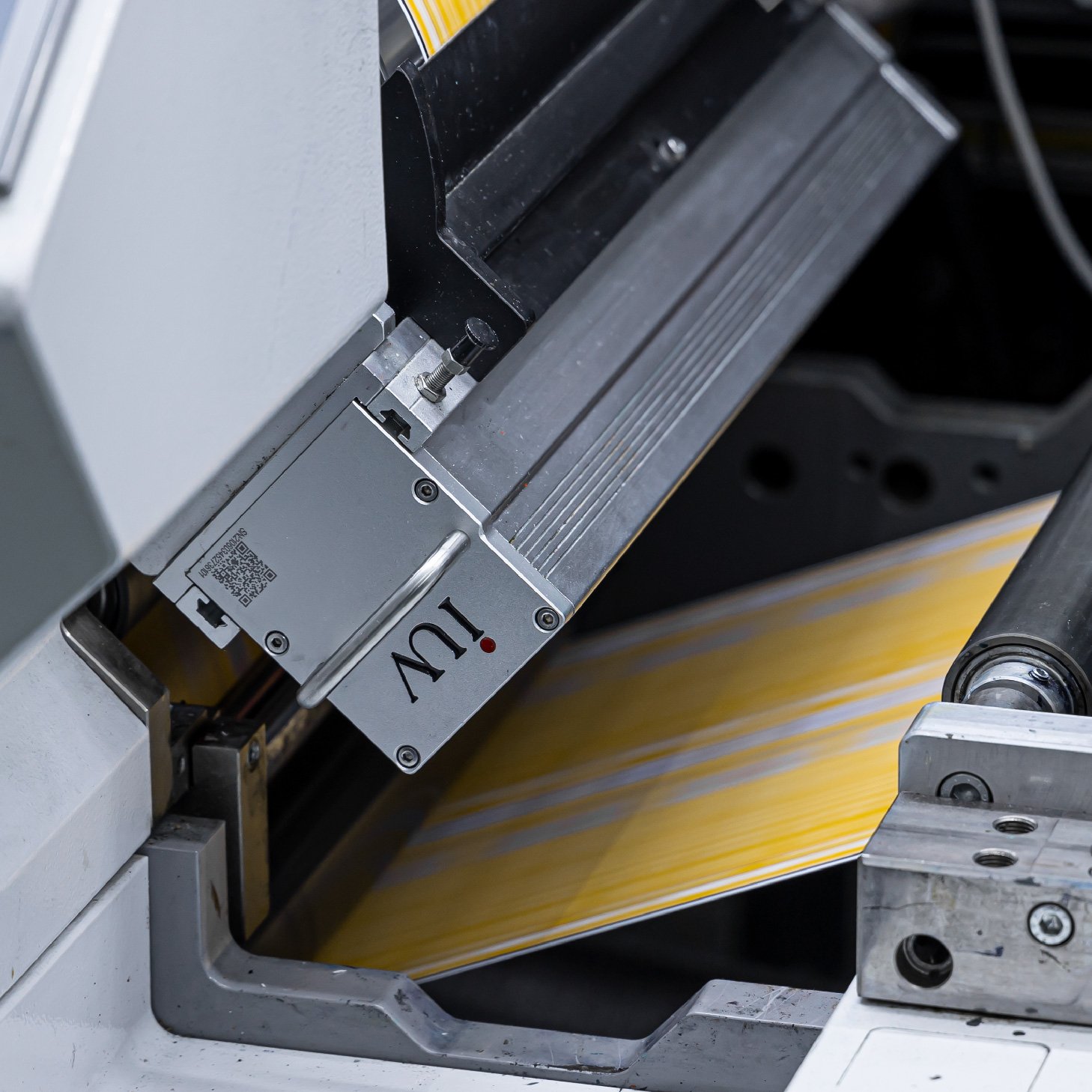

UV curing technology uses ultraviolet light to instantly dry or “cure” inks and coatings. This process happens almost immediately after the ink is applied to the substrate. In flexographic printing, this rapid drying is a crucial advantage. It prevents ink from smearing or bleeding. This means less ink is needed to achieve sharp, vibrant graphics. The precision offered by UV curing is unmatched by older drying technologies.

Traditional solvent-based inks require heat to evaporate the solvent. This evaporation process is slow. It necessitates large drying units. These units can lead to ink pooling or over-application to compensate for drying time. Furthermore, solvent evaporation releases volatile organic compounds (VOCs). These VOCs pose environmental concerns and require expensive exhaust systems. UV curable inks, in contrast, do not rely on evaporation. They cure through a photochemical process. This process solidifies the ink instantly.

The direct impact on ink waste is profound. With UV curing, printers can apply thinner ink films. These thin films achieve the same opacity and color density as thicker films from conventional inks. This direct reduction in ink consumption directly translates to lower material costs. Less ink wasted means more prints from the same amount of ink. This improves the bottom line for label converters and other narrow web printers.

Beyond the ink itself, UV curing systems contribute to waste reduction in other areas. For instance, the faster drying speeds allow for quicker job changeovers. Less time is spent waiting for ink to dry between runs. This reduces the amount of substrate that might be wasted during setup. The precision of UV curing also leads to fewer printing errors. Misprints due to smudging or poor drying are drastically reduced. Each misprint represents wasted ink, substrate, and production time.

LED UV curing technology represents the latest advancement in this field. Compared to traditional mercury lamp UV systems, LED UV offers even greater benefits. LEDs are highly energy-efficient. They consume significantly less power than mercury lamps. This energy saving further reduces operational costs. Importantly, LEDs also produce less heat. Excessive heat can distort thinner substrates, leading to waste. The controlled heat output from LEDs ensures substrate integrity. This minimizes potential material spoilage.

The spectral output of LED UV lamps is also more precise. This allows for optimized ink formulation. Printers can work with ink manufacturers to develop UV inks specifically tuned to the LED’s wavelength. This fine-tuning ensures maximum cure efficiency. It further reduces the amount of ink needed for a perfect result. The reliability and longevity of LED lamps also contribute to smoother operations. Reduced downtime for lamp replacement means more consistent production. This consistency inherently minimizes waste.

In the competitive landscape of label printing, every efficiency gain matters. Flexographic printing for packaging and product labels demands high quality and speed. UV curing systems directly address these demands. They enable printers to achieve vibrant colors and sharp text consistently. The immediate curing ensures that the ink stays exactly where it’s placed. This is vital for fine details and intricate designs often found on labels.

Consider the environmental aspect as well. By reducing ink waste, UV curing systems contribute to a more sustainable printing process. Less ink produced means less raw material used and fewer manufacturing emissions. The elimination or significant reduction of VOCs from solvent-based inks is another major environmental benefit. This aligns with the growing demand for eco-friendly printing solutions from brand owners and consumers.

The transition to UV curing involves an initial investment in the curing equipment. However, the long-term savings are substantial. Reduced ink consumption, less substrate waste, lower energy bills, and improved throughput all contribute to a strong return on investment. For narrow web flexographic printers, especially those focused on high-volume label production, this technology is not just an option; it’s becoming a necessity.

The reliability of modern UV curing systems ensures consistent performance. This consistency is key to maintaining high print quality. It also directly impacts the reduction of waste. When a system performs predictably, there are fewer unexpected issues that could lead to scrapped jobs. The ease of integration into existing flexographic presses is another advantage. Many narrow web presses are designed to accommodate UV curing units with relative ease.

Ink waste in flexographic printing is a multifaceted problem. It encompasses unused ink, over-application, misprints, and setup waste. UV curing systems tackle this problem holistically. They provide a technological solution that benefits both the printer’s bottom line and the environment. The precision, speed, and efficiency offered by UV and especially LED UV curing make it an indispensable tool for modern flexographic label printing operations seeking to optimize their processes and reduce their environmental footprint. The future of efficient, low-waste flexographic printing is undeniably linked to the advancement and adoption of UV curing technology.