Unlock Superior Print Performance with UV Curing Technology

In the competitive world of print, delivering products that not only look good but also stand the test of time is paramount. Print durability and resistance are no longer optional features; they are essential requirements for a wide range of applications, from demanding industrial labels to eye-catching packaging. The good news is that advancements in UV curing systems are revolutionizing how we achieve these critical qualities.

The Science Behind UV Curing

UV curing is a photochemical process. It uses high-intensity ultraviolet light to instantly dry or cure inks, coatings, and adhesives. Unlike traditional heat or solvent drying, UV curing relies on a chemical reaction initiated by UV light. This reaction causes monomers and oligomers within the ink or coating to polymerize, forming a solid, cross-linked film. This rapid transformation is what gives UV-cured prints their exceptional properties.

Why Durability Matters in Print

Consider the journey of a product label. It might endure exposure to moisture, abrasion from handling, chemicals in cleaning products, or intense sunlight. Packaging faces its own set of challenges, from stacking pressure to friction during transport. When print fades, scratches, or smears, it diminishes the brand’s image and can even render the product information illegible. This is where the resilience provided by UV curing systems becomes invaluable.

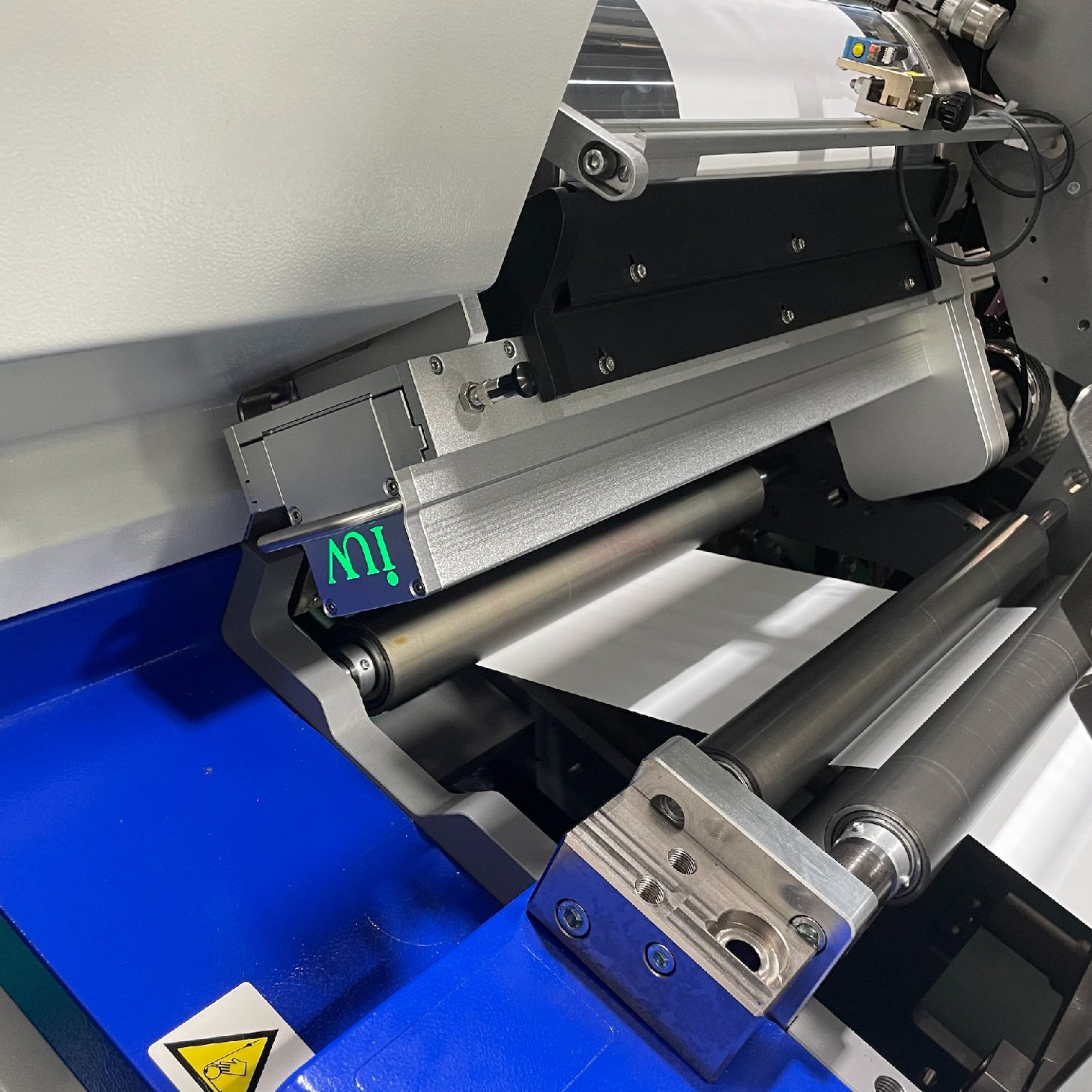

UV Curing for Narrow Web Printing

Narrow web printing, often utilizing flexographic (flexo) and offset presses, is a cornerstone for producing labels and flexible packaging. These markets demand high throughput and superior finished product quality. UV curing has become a dominant technology in this sector for several compelling reasons.

Flexo and offset presses for narrow web applications often run at high speeds. Traditional drying methods can struggle to keep up without compromising print quality or requiring excessive machine length. UV curing, however, offers instantaneous drying. This means inks and coatings are fully cured as they exit the press, eliminating the need for long drying tunnels. This space-saving advantage is a significant benefit for press manufacturers and print businesses alike.

Furthermore, the immediate cure prevents ink migration or smudging. This is critical for food packaging labels where safety and compliance are paramount. It also means that subsequent finishing processes, such as die-cutting or slitting, can occur immediately after printing without damaging the freshly printed image.

Enhanced Resistance Properties with UV Curing

The cross-linked polymer network formed during UV curing creates a significantly more robust print surface. This translates into a remarkable improvement in resistance to various environmental and physical stresses.

- Abrasion Resistance: UV-cured inks and coatings form a hard, durable surface that is highly resistant to scratching and scuffing. This is vital for labels on products that are frequently handled, such as beverage bottles, automotive parts, or industrial equipment. Think of how often a product label is rubbed during its lifecycle – UV curing ensures it remains pristine.

- Chemical Resistance: The tightly bound molecular structure of UV-cured films makes them impervious to many common chemicals. This includes oils, greases, solvents, and even some harsh cleaning agents. This property is indispensable for labels on cleaning products, automotive fluids, and laboratory samples.

- Moisture and Water Resistance: UV curing creates a barrier that effectively repels water and moisture. This prevents ink from bleeding, fading, or lifting when exposed to humidity, condensation, or direct water contact. This is a key advantage for labels used in humid environments like bathrooms, kitchens, or outdoor applications.

- Fade Resistance: While not a replacement for specialized UV-protective coatings, the inherent density and structure of UV-cured inks can offer improved resistance to fading from UV light exposure compared to some conventional inks. This is beneficial for products displayed under bright retail lighting or those intended for outdoor use.

LED UV Curing: The Next Evolution

While traditional mercury-vapor UV lamps have been the workhorse for UV curing, the advent of LED UV technology represents a significant leap forward. LED UV systems offer numerous advantages that further enhance print durability and operational efficiency.

LEDs emit UV light at specific wavelengths, precisely matched to the photoinitiators in the ink. This targeted energy delivery leads to more efficient and complete curing. The result is an even tougher, more resilient print surface.

Operational benefits are also substantial. LEDs have a much longer lifespan than mercury lamps, reducing maintenance and replacement costs. They consume less energy, leading to significant cost savings and a smaller environmental footprint. Crucially, LEDs generate very little heat, which is a major advantage for heat-sensitive substrates common in narrow web printing, preventing substrate distortion and enabling the use of a wider variety of materials.

Applying UV Curing Across Printing Methods

The benefits of UV curing extend across various printing processes:

- Flexographic Printing: UV inks are widely used in flexo for labels and packaging. They provide vibrant colors, sharp details, and the necessary durability for consumer goods. The instant cure allows for faster production speeds and inline finishing capabilities.

- Offset Printing: For narrow web offset presses, UV inks enable high-quality graphics with excellent resistance properties. This is ideal for high-end labels, promotional materials, and specialty packaging where visual appeal and tactile durability are important.

- Other Applications: Beyond labels and packaging, UV curing is essential for applications like security printing, decorative laminates, and industrial markings where extreme durability is a requirement.

The Bottom Line: Investing in Resilience

By embracing UV curing systems, particularly modern LED UV technology, print providers can elevate the performance of their output. The enhanced durability and resistance against abrasion, chemicals, and moisture ensure that printed products maintain their integrity and visual appeal throughout their intended lifecycle. This not only satisfies demanding customer requirements but also strengthens brand reputation and opens doors to new, high-value applications. It’s a smart investment in quality, efficiency, and long-term print performance.