Achieving vibrant and consistent colors is a constant pursuit in label printing. Flexographic printing, often called flexo, offers speed and versatility. However, maintaining exact color reproduction across a print run can present challenges. This is where advanced UV curing systems step in, bringing significant improvements to color consistency.

The process of flexographic printing involves flexible relief plates. Ink is transferred from the plate to the substrate. For label printing, precision is paramount. Customers expect their brand colors to look the same on every label, every time. Fluctuations in color can lead to costly reprints and damage brand perception.

Traditional drying methods in printing can sometimes struggle to keep pace. This can affect how inks behave on the press. Factors like ink viscosity and drying speed play a critical role. If ink doesn’t dry uniformly, it can lead to issues like ink starvation or over-application. These problems directly impact the final color output.

UV curing technology offers a powerful solution. It uses ultraviolet light to instantly dry or “cure” inks, coatings, and adhesives. Instead of evaporating solvents, UV curing initiates a photochemical reaction. This reaction transforms the liquid ink into a solid, durable film.

One of the primary ways UV curing enhances color consistency is through precise ink control. Because the ink cures almost instantaneously, it doesn’t have time to spread or bleed on the substrate. This means the dots and lines printed retain their sharp edges. For color fidelity, this sharp definition is crucial. It ensures that the intended color build-up is achieved accurately.

Consider the challenge of color matching. Printers often use a combination of CMYK (Cyan, Magenta, Yellow, Black) inks, along with spot colors, to achieve a desired shade. In flexographic printing, the way these inks interact and dry can alter the final appearance. If inks dry too slowly or unevenly, the color can appear duller or shift in hue.

UV curing, particularly LED UV curing, provides a much more controlled drying environment. As the ink passes under the UV lamps, it’s exposed to a specific wavelength and intensity of light. This rapid curing locks in the color as it’s printed. There’s no opportunity for environmental factors like humidity or air flow to affect the drying process and, consequently, the color.

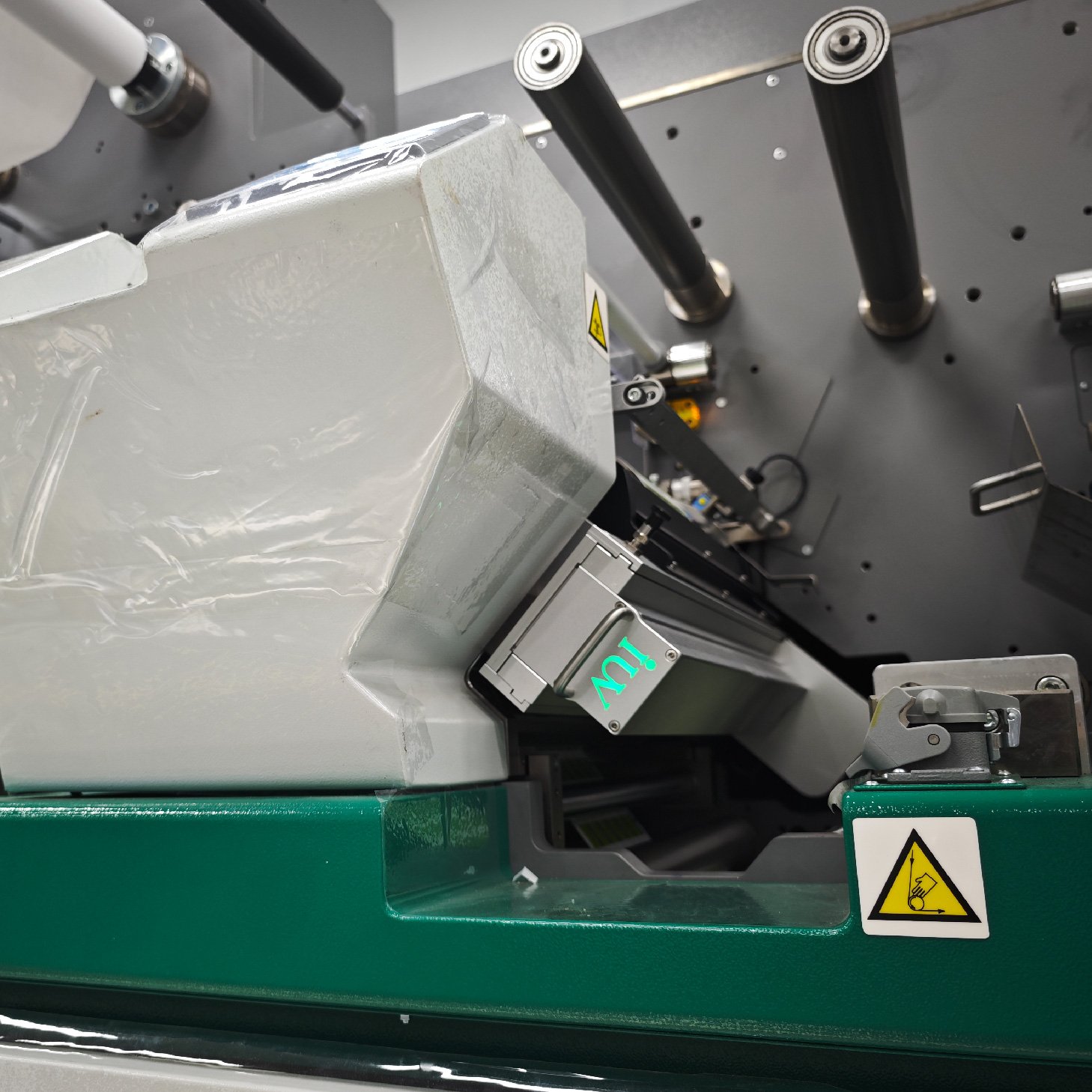

LED UV curing systems are a significant advancement over traditional mercury vapor lamps. LEDs offer a more focused and stable output of UV energy. This means the curing process is more consistent from the beginning of a print job to the end. It also allows for precise control over the curing intensity and duration. This level of control directly translates to more predictable color results.

Furthermore, UV inks themselves are formulated differently. They are designed to react quickly to UV light. This means they contain photoinitiators that kickstart the curing process. When cured properly, these inks form a robust layer that resists abrasion and chemicals. Crucially for color, the cured ink film is less susceptible to changes caused by subsequent printing stations or finishing processes.

In narrow web printing, which is common for labels and packaging, space and speed are often at a premium. UV curing systems integrate seamlessly into these presses. They are compact and efficient. The fast curing times mean presses can run at higher speeds without compromising print quality or color consistency. This speed advantage is vital for meeting production demands.

The alternative to UV curing in some flexo applications might involve heat-set or air-drying inks. These methods can introduce variability. Heat can sometimes alter the substrate, affecting ink adhesion and appearance. Air drying is highly dependent on ambient conditions. UV curing bypasses these variables, offering a more reliable path to consistent color.

Think about the impact on screen printing or offset printing (also known as lithographic printing). While these processes have their own strengths, flexo, especially with UV curing, excels in certain areas like packaging. The ability to print on a wide range of substrates, from thin films to thicker boards, is a flexo hallmark. Ensuring color consistency across these diverse materials is made much easier with UV.

Brand owners often have strict color palettes. For example, a specific shade of red or blue for a beverage label needs to be exact. Any deviation can be easily spotted by consumers. UV curing helps printers achieve these exacting standards by ensuring that the ink is deposited and cured in a stable manner. This minimizes the chances of color drift.

The technology also supports the use of high-quality coatings and varnishes. These can be UV-curable as well. Applying a clear UV varnish over printed colors can enhance their vibrancy and depth. Because the varnish cures instantly, it doesn’t interact negatively with the underlying inks, preserving the intended color.

In essence, the UV curing system acts as a stabilizing force within the flexographic printing process. It removes many of the variables that can lead to color inconsistency. By providing rapid, controlled, and efficient drying, it allows printers to consistently deliver high-quality, color-accurate labels. This reliability is invaluable for businesses that depend on strong brand recognition and visually appealing products. The investment in a modern UV curing system, especially an LED UV system, can lead to significant improvements in overall print quality and customer satisfaction.