Choosing the Perfect LED UV Curing System for Your Printing Needs

Selecting the right LED UV curing system is key for efficient and high-quality printing. This decision impacts everything from print speed to ink adhesion. Let’s explore how to make the best choice for your specific application.

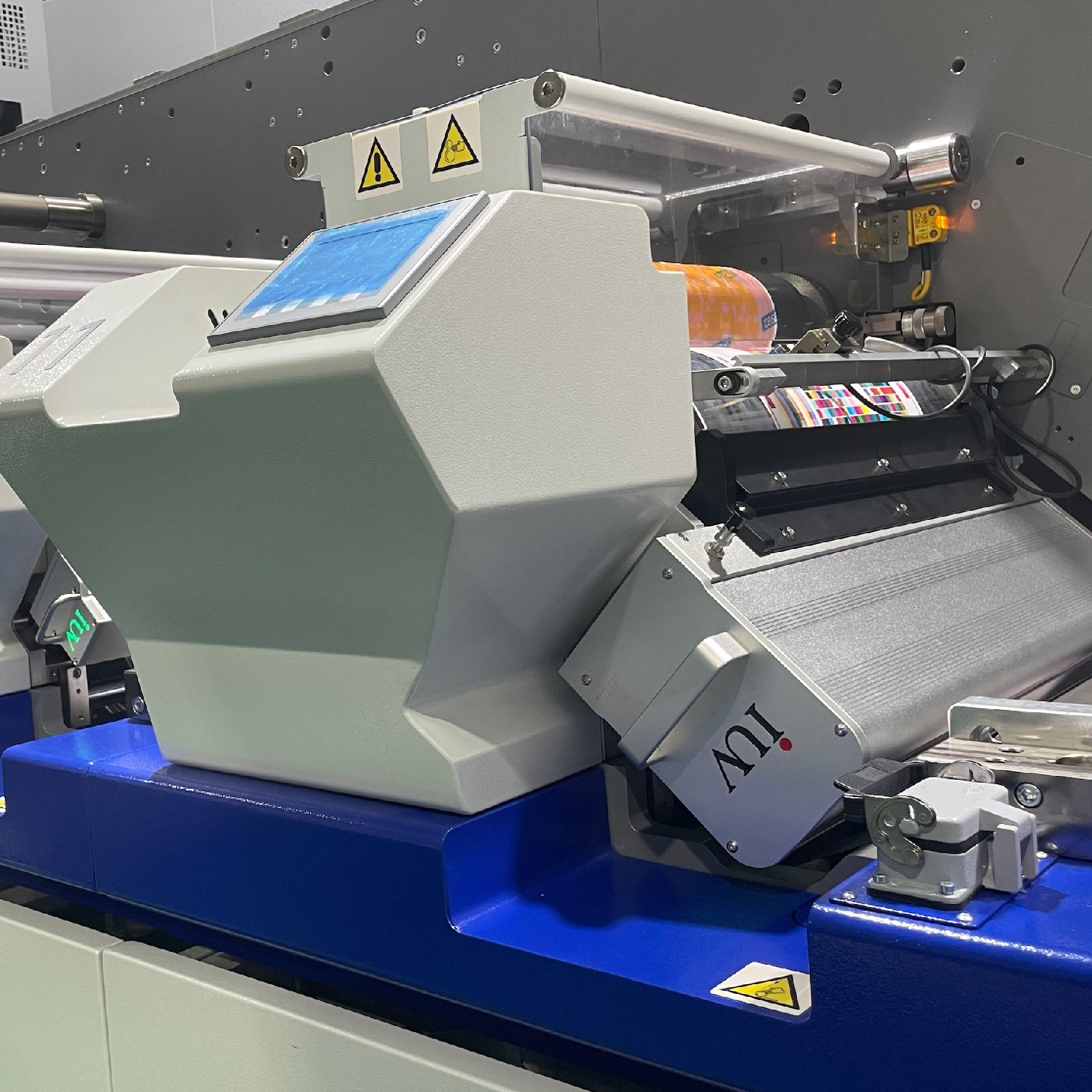

Understanding LED UV Curing Technology

LED UV curing uses ultraviolet light to instantly dry or cure inks, coatings, and adhesives. Unlike traditional mercury lamps, LED systems offer several advantages. They are more energy-efficient, have a longer lifespan, and produce less heat. This means lower operating costs and a safer working environment.

The core of LED UV curing lies in the specific wavelengths of light emitted. These wavelengths must match the photoinitiators within your ink or coating. Different inks require different UV spectrums for optimal curing.

Key Factors to Consider

When selecting an LED UV curing system, several factors come into play. These include the type of printing press, the substrate being used, and the desired curing speed.

1. Printing Application:

- Label Printing: This often involves printing on various materials like paper, film, and foil. The system must handle high speeds and ensure excellent ink adhesion for durability. Narrow web printing, a common method for labels, requires compact and efficient curing solutions.

- Flexographic Printing (Flexo): Flexo printing is versatile and used for packaging, labels, and more. LED UV curing in flexo needs to be robust enough to handle continuous operation and different ink formulations. Ensuring proper cure across the entire print width is vital.

- Offset Printing (Sheetfed and Web): Offset printing, especially for commercial applications, demands precise curing for sharp dots and vibrant colors. Sheetfed offset requires systems that can be easily integrated into existing presses, while web offset needs high-speed, long-lasting solutions.

2. Substrate Compatibility:

The material you are printing on is a critical consideration. Some substrates are sensitive to heat. LED UV curing’s low heat output makes it ideal for delicate materials like thin films, plastics, and certain types of paper.

- Plastics and Films: These often require specific wavelengths to ensure the ink bonds properly without damaging the substrate.

- Paper and Cardboard: While generally more resilient, achieving good adhesion and rub resistance is still important.

- Metals and Other Non-Porous Materials: These substrates often necessitate specialized inks and a curing system capable of delivering the required energy for complete cure.

3. Ink and Coating Chemistry:

The formulation of your ink or coating is paramount. Each ink contains photoinitiators that react to specific UV wavelengths.

- Wavelength Selection: Ensure the LED UV system emits the correct wavelengths (e.g., 365nm, 385nm, 395nm, 405nm) to activate your ink’s photoinitiators. Many modern UV inks are formulated for a broad range of wavelengths.

- Energy Output (Irradiance): The intensity of the UV light, measured in Watts per square centimeter (W/cm²), dictates how quickly the ink cures. Higher irradiance generally leads to faster curing.

- Dose (Energy per Area): This is the total amount of UV energy delivered, calculated by multiplying irradiance by exposure time (Joules/cm²). A sufficient dose is needed for full cure.

4. Press Speed and Throughput:

Your printing press speed directly influences the required curing power. A faster press needs a higher irradiance and potentially a longer curing zone to ensure complete drying.

- Narrow Web Presses: These often operate at very high speeds. The LED UV system must be able to keep up without compromising cure quality.

- Sheetfed Presses: While speeds might be lower than web presses, the system needs to provide consistent curing across each sheet.

5. System Integration and Footprint:

Consider how the LED UV system will fit into your existing printing press.

- Air or Water Cooling: Some systems require air cooling, while others use water. This impacts installation and maintenance requirements.

- Physical Size: Ensure the system’s dimensions are compatible with your press layout. Compact designs are often preferred for ease of integration.

6. Environmental and Operational Benefits:

Beyond print quality, think about the broader advantages.

- Energy Savings: LED systems consume significantly less power than mercury lamps.

- Reduced Heat: This protects heat-sensitive substrates and reduces the need for extensive cooling.

- Longer Lifespan: LED lamps last much longer, reducing replacement costs and downtime.

- Instant On/Off: Unlike mercury lamps that require warm-up time, LEDs are ready immediately, saving energy and reducing wear.

- Mercury-Free: A significant environmental advantage, eliminating the need to dispose of hazardous mercury.

Making the Final Decision

By carefully evaluating your printing application, substrate, ink requirements, and press speed, you can confidently select an LED UV curing system. Consulting with your ink supplier and the LED UV system manufacturer is always a wise step. They can provide expert guidance tailored to your specific needs, ensuring you achieve optimal results and maximize your printing efficiency. Investing in the right LED UV system is an investment in quality, speed, and sustainability for your printing operation.