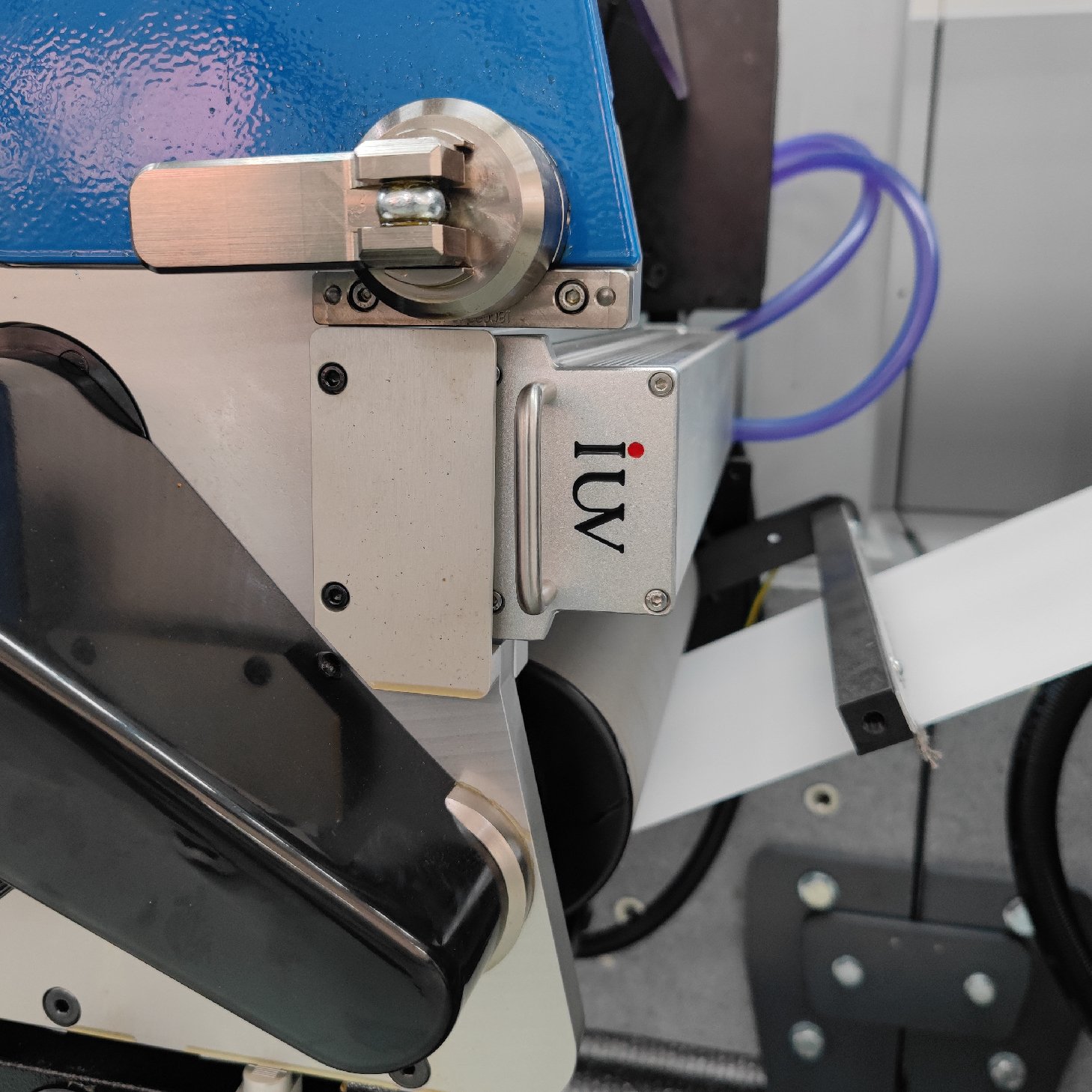

Achieving exceptional label print quality hinges on meticulous control over every production variable. Among these, the UV curing process plays a pivotal role, especially with the increasing adoption of LED UV technology. For narrow web printers, whether employing flexographic or offset techniques, understanding how to fine-tune LED UV curing settings is not just beneficial—it’s paramount to consistent, high-quality output.

This article delves into the core principles and practical applications of optimizing LED UV curing for label printing. We’ll explore how precise adjustments to lamp power, exposure time, and distance can dramatically impact adhesion, gloss, scratch resistance, and color vibrancy, ensuring your labels stand out in a competitive market.

Understanding the Science of UV Curing

UV curing, or ultraviolet curing, is a photochemical process where high-intensity ultraviolet light is used to instantly dry or cure inks, coatings, and adhesives. This process relies on photoinitiators within the formulation. When exposed to UV light of a specific wavelength, these photoinitiators absorb the energy and trigger a rapid polymerization reaction, transforming the liquid ink or coating into a solid, cross-linked film.

LED UV curing offers distinct advantages over traditional mercury vapor lamps. LEDs emit a narrower spectrum of UV light, typically in the UVA range (320-400 nm), which is highly efficient for initiating polymerization. This focused energy delivery leads to more controlled and consistent curing, reduced heat generation, and a longer lamp lifespan.

Key Parameters for Fine-Tuning LED UV Curing

Optimizing LED UV curing involves carefully managing three primary parameters:

- Lamp Power (Irradiance): This refers to the intensity of the UV light emitted by the LED lamps, measured in milliwatts per square centimeter (mW/cm²). Higher power delivers more energy to the ink film, accelerating the curing reaction. However, excessive power can lead to surface cure without through-cure, or even degrade the substrate.

- Exposure Time (Dwell Time): This is the duration for which the substrate remains under the UV light source. It’s directly related to the speed of the printing press. A longer exposure time allows more UV energy to be absorbed by the photoinitiators, ensuring complete polymerization.

- Distance (Lamp-to-Substrate Gap): The physical distance between the LED lamps and the surface of the printed material. As the distance increases, the UV irradiance decreases significantly following the inverse square law. Maintaining an optimal, consistent gap is crucial for uniform energy delivery across the entire print.

Impact of Curing on Label Print Quality

The effectiveness of your LED UV curing settings directly influences several critical aspects of label print quality:

- Adhesion: Proper curing ensures the ink bonds securely to the substrate. Inadequate curing can result in delamination, especially under stress, or poor resistance to chemicals and scuffing.

- Scratch and Abrasion Resistance: A fully cured ink film forms a hard, durable surface. Insufficient curing leaves the ink vulnerable to damage during handling, transportation, and application.

- Gloss and Appearance: Curing affects the surface characteristics of the ink. Optimal settings contribute to achieving the desired gloss levels, whether matte or high-gloss finishes, and prevent premature dulling or hazing.

- Color Vibrancy and Consistency: UV curing locks in the pigment and binder, preserving the intended color richness. Incomplete curing can lead to color shifts or a faded appearance.

- Chemical Resistance: Labels often encounter various chemicals. A properly cured ink film provides a barrier against solvents, oils, and cleaning agents.

Optimizing Settings for Different Printing Processes

While the core principles apply broadly, specific considerations emerge depending on whether you are using flexographic or offset printing for your narrow web labels.

Flexographic Printing and LED UV Curing

Flexography is a high-speed, versatile printing method widely used for labels. When using LED UV curing in flexo, consider:

- Ink Film Thickness: Flexo inks are typically applied in thinner layers compared to offset. This means they cure faster. You might require lower power settings or shorter exposure times to prevent over-curing or substrate damage.

- Anilox Roll Selection: The cell volume and screen count of your anilox roll dictate ink transfer. A higher ink transfer (larger volume anilox) will necessitate adjustments to curing parameters to ensure thorough polymerization of the thicker ink film.

- Screen Tension and Substrate Stretch: In flexo, maintaining consistent print geometry is vital. Over-curing can sometimes lead to shrinkage or distortion, especially on thinner films. Monitor registration and dot gain closely.

- Spot vs. Process Colors: Different ink formulations for spot colors or process colors may have varying photoinitiator packages and pigment loads. Each color group might require unique curing profiles.

Offset Printing (Sheetfed/Web Offset) and LED UV Curing

Offset printing, particularly for labels on narrow web presses, also benefits greatly from precise LED UV control:

- Ink Layer Thickness: Offset inks are generally applied in thicker layers than flexo inks. This requires robust curing power and/or sufficient dwell time to ensure the entire ink film polymerizes, especially in deeper layers.

- Dot Reproduction: Achieving sharp, well-defined dots is critical in offset. Inadequate curing can lead to “muddy” dots or poor ink trap between colors. Over-curing might cause ink to “fountain” or bleed, creating halo effects.

- Water/Ink Balance: In traditional offset, managing water balance is key. With UV inks, this is less of an issue, but the interaction of UV energy with water-based fountain solutions (if used in hybrid systems) needs consideration.

- Substrate Porosity: Porous substrates absorb ink differently. While UV curing focuses on surface drying, understanding substrate interaction is still important.

Practical Steps for Fine-Tuning

Here’s a systematic approach to fine-tuning your LED UV curing settings:

- Start with Manufacturer Recommendations: Always begin with the ink and coating manufacturer’s recommended curing parameters. These are based on their specific formulations.

- Calibrate Your Equipment: Ensure your LED UV system is properly calibrated. Verify the output power using a radiometer and confirm the lamp’s effective wavelength matches the photoinitiator’s absorption spectrum.

- Test on the Target Substrate: Conduct all tests on the actual substrate you will be using for production. Different materials absorb and reflect UV light differently.

- Isolate Variables: When testing, change only one parameter at a time (power, speed/time, or distance). This allows you to isolate the effect of each variable.

- Use a Test Pattern: Employ a test pattern that includes solid areas, fine lines, small text, and screens. This will help you assess curing across various ink film thicknesses and densities. Include color patches with high ink coverage.

- Perform Adhesion Tests: After curing, immediately perform cross-hatch adhesion tests (ASTM D3359) and tape adhesion tests. Scratch resistance tests using a standardized stylus or abrasion tester are also crucial.

- Evaluate Visual Quality: Inspect the print for gloss, color saturation, registration, dot clarity, and any signs of defects like webbing, shrinkage, or yellowing.

- Gradually Adjust: If adhesion or resistance is insufficient, gradually increase lamp power or decrease press speed (increase dwell time). If you notice substrate degradation, excessive shrinkage, or surface scorching, reduce power or increase the lamp-to-substrate distance.

- Consider Ink Formulation: Different UV ink systems (e.g., acrylate-based, epoxy-based) have different curing speeds and energy requirements. Always refer to the ink supplier for specific guidance.

- Monitor Temperature: While LED UV lamps generate less heat than mercury lamps, excessive exposure or insufficient ventilation can still lead to substrate heating. Monitor substrate temperature, especially with heat-sensitive materials.

Common Pitfalls to Avoid

- Under-Curing: This is the most common issue, leading to poor adhesion, scratchability, and chemical resistance. Always err on the side of slightly over-curing if in doubt.

- Over-Curing: Can cause brittleness, yellowing, shrinkage, and substrate damage. It can also waste energy.

- Inconsistent Irradiance: Ensure uniform UV intensity across the entire web width. Check for dead spots or areas of lower intensity due to lamp alignment or damage.

- Ignoring Photoinitiator Saturation: After a certain point, adding more UV energy won’t improve curing and may become detrimental.

- Not Accounting for Press Speed: The relationship between press speed and dwell time is direct. Changes in speed necessitate re-evaluation of curing parameters.

The Future of LED UV Curing in Label Printing

As technology advances, LED UV curing systems are becoming more efficient, offering precise control over spectral output and energy delivery. This allows printers to achieve higher print speeds, expand their substrate capabilities (including heat-sensitive materials), and reduce their environmental impact due to lower energy consumption and absence of mercury.

For narrow web printers focused on producing high-quality labels, mastering the art of fine-tuning LED UV curing settings is an ongoing process. By understanding the science, systematically testing, and adapting to different inks and substrates, you can consistently deliver labels that meet and exceed customer expectations for durability, appearance, and performance. Embracing these optimizations will undoubtedly set your label printing operation apart.