Choosing the right LED UV curing system is a critical decision for any printing operation. It directly impacts print quality, production speed, and operational costs. This is especially true in specialized printing sectors like label printing, flexography, offset printing, and narrow web printing, where precise control and consistent performance are paramount. Understanding the nuances of LED UV curing technology and how it integrates with your specific press and application is key to making an informed choice.

Understanding LED UV Curing Technology

LED UV curing uses ultraviolet light emitted by Light Emitting Diodes (LEDs) to instantly cure inks, coatings, and adhesives. Unlike traditional mercury vapor lamps, LEDs offer a more focused spectrum of UV light, generate less heat, and have a significantly longer lifespan. This translates to energy savings, reduced maintenance, and improved working conditions.

The effectiveness of LED UV curing depends on several factors: the wavelength of the UV light, the irradiance (intensity) of the light, and the exposure dose (the total amount of UV energy delivered). Different inks and coatings are formulated to cure at specific wavelengths, typically in the UVA range (365 nm, 395 nm, 405 nm). Matching the LED system’s output to the ink’s requirements is fundamental.

Key Considerations for Your Press and Application

When selecting an LED UV curing system, several factors need careful evaluation to ensure optimal compatibility and performance with your printing press and intended applications.

1. Ink and Coating Compatibility

This is the most important starting point. Different inks and coatings require specific UV wavelengths and energy levels for proper curing.

- Wavelength: Ensure the LED system’s wavelength output matches the spectral requirements of your chosen inks and coatings. Common wavelengths for LED UV curing include 365 nm, 395 nm, and 405 nm. Some specialized inks might require other wavelengths. Always consult with your ink supplier for their recommendations.

- Energy Requirements: Determine the UV energy (dose) needed for your specific inks and coatings. This is often expressed in Joules per square centimeter (J/cm²). The LED system must be capable of delivering this dose reliably at your desired press speeds.

2. Press Type and Configuration

The type of printing press you operate will heavily influence the type of LED UV curing system you can use.

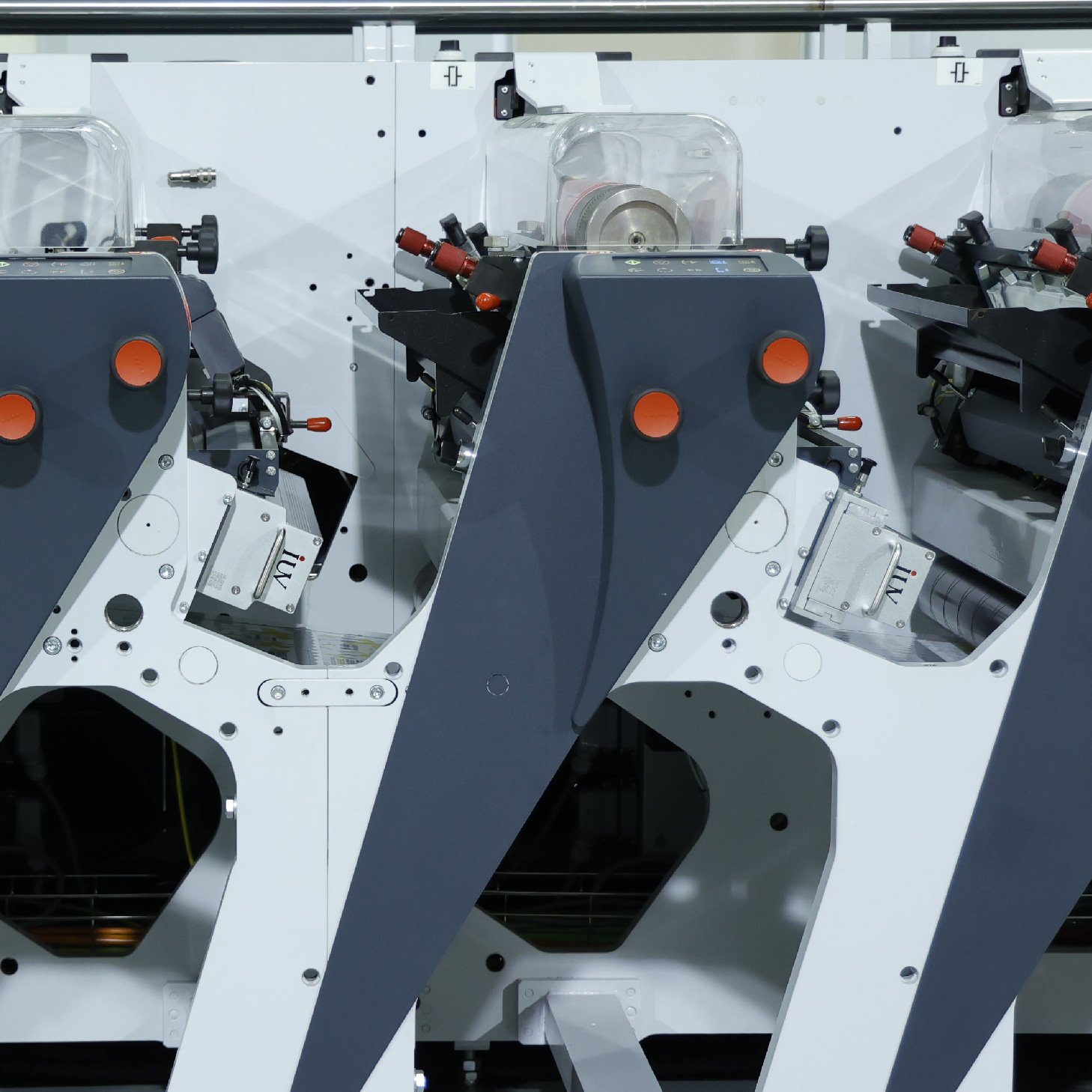

- Narrow Web Presses: For label and flexible packaging printing, narrow web presses often have limited space. Compact, air-cooled LED UV systems are frequently the preferred choice. These systems can be easily integrated between printing units or at the end of the press.

- Flexographic Presses: Flexo presses, particularly those used for packaging, can benefit from LED UV curing for enhanced print speed and substrate versatility. The placement of the UV units is crucial to ensure efficient curing without affecting web handling.

- Offset Presses: In offset printing, especially for commercial applications or packaging, LED UV curing can significantly improve throughput and substrate options. Integration can be at the delivery end or between units. The higher heat output of some offset presses might necessitate robust cooling solutions for the LED system.

- Rotary Screen Printing: For applications requiring heavy ink laydowns, LED UV curing can provide rapid surface cure, preventing smudging and allowing for immediate post-processing.

3. Application Requirements

The end-use of the printed product dictates certain performance criteria for the curing system.

- Adhesion and Durability: For demanding applications like food packaging or labels exposed to harsh environments, excellent adhesion and scratch resistance are essential. The LED UV system must provide complete through-cure to achieve these properties.

- Color Fidelity: Consistent curing ensures stable color reproduction. LED systems, with their stable output, contribute to predictable color results.

- Substrate Types: LED UV curing works well on a wide range of substrates, including paper, cardboard, plastics, and some heat-sensitive materials. The lower heat output of LEDs is particularly advantageous for heat-sensitive substrates.

4. Press Speed and Throughput

Your production speeds are a primary driver for selecting an LED UV system.

- Irradiance and Speed: The irradiance of the LED system (measured in W/cm²) dictates how quickly it can cure inks at a given press speed. Higher irradiance allows for faster press speeds while still achieving full cure. Calculate the required irradiance based on your press speed and the energy dose needed by your inks.

- Number of UV Units: For high-speed presses or applications requiring multiple ink colors and coatings, you may need multiple LED UV curing units strategically placed throughout the press.

5. Cooling Method

LED UV lamps generate heat, and effective cooling is vital for both performance and longevity.

- Air-Cooled Systems: These are common for narrow web and smaller applications. They are generally more compact and easier to install. However, they may have limitations in very high-irradiance applications or in environments with poor ventilation.

- Water-Cooled Systems: For higher power requirements and industrial-scale printing, water-cooled systems are often necessary. They offer superior heat dissipation, allowing for higher irradiance and more stable performance, especially in demanding environments.

6. Lamp Configuration and Placement

The physical design and placement of the LED UV units are critical for effective curing.

- Lamp Width: The LED curing unit should be wide enough to cover the entire web or sheet width to ensure uniform curing.

- Lamp Housing: The housing design impacts airflow and heat management. Some systems are designed for inline mounting between print units, while others are designed for end-of-press installation.

- Reflectors: While LEDs are directional, some systems incorporate reflectors to optimize light distribution and ensure even coverage across the substrate.

- Distance to Substrate: The optimal distance between the LED lamp and the substrate is important. Too far, and intensity drops significantly; too close, and it can cause issues with ink cooling or substrate handling.

7. Energy Efficiency and Operational Costs

LED UV curing is known for its energy efficiency compared to traditional UV lamps.

- Power Consumption: Compare the power consumption of different LED systems. While the upfront cost might be higher, the long-term energy savings can be substantial.

- Lamp Lifespan: LEDs have a much longer operational life (typically 20,000-50,000 hours or more) than mercury lamps, reducing replacement frequency and associated costs.

- Maintenance: Lower heat output means less strain on press components and potentially fewer maintenance issues related to heat damage.

8. Environmental Considerations

The environmental benefits of LED UV curing are significant.

- No Ozone Production: Unlike mercury lamps, LEDs do not produce ozone, improving workplace air quality and reducing the need for exhaust systems.

- Lower CO2 Footprint: Reduced energy consumption contributes to a smaller carbon footprint.

- No Mercury: LED systems eliminate the hazardous waste associated with mercury lamp disposal.

Practical Steps for Selection

- Consult Your Ink and Coating Suppliers: Obtain specific recommendations for wavelength and energy requirements for your chosen materials.

- Assess Your Press Capabilities: Understand the space available, power supply, and existing cooling infrastructure on your press.

- Define Your Production Needs: Determine your maximum press speeds and desired throughput.

- Request Demonstrations and Samples: Arrange for the LED UV system manufacturer to test their equipment with your specific inks, substrates, and press conditions. This is invaluable for verifying performance.

- Compare Quotes and Technical Specifications: Don’t just look at price. Evaluate the technical specifications, warranty, and after-sales support offered by different vendors.

- Consider Future Needs: Think about whether your printing applications might evolve, and choose a system that offers some flexibility.

By carefully considering these factors, you can confidently select an LED UV curing system that enhances your printing operations, delivering superior quality, efficiency, and cost-effectiveness for your label, flexo, offset, or narrow web applications.