The realm of narrow-web flexographic printing is constantly seeking avenues to enhance efficiency and sustainability. For label converters, this means not only achieving vibrant, high-quality prints but also minimizing material waste and ensuring impeccable registration. Enter the advanced capabilities of narrow-web LED flexo systems, a technology that directly addresses these critical concerns.

Precision Engineering in Narrow-Web Flexo

Traditional flexographic printing, particularly on narrow-web presses, has always been a balancing act. The inherent flexibility of the printing plates and the rapid nature of the process can sometimes lead to challenges in maintaining exact registration, especially during extended runs or when dealing with intricate designs. Register accuracy is paramount in label printing; misaligned colors can render a product visually unappealing and, in some cases, illegible, leading to product rejection and significant waste.

Flexo printing relies on raised image plates, which transfer ink to the substrate. The process involves multiple stations, each applying a different color. For perfect results, each station must lay down its ink precisely where it’s intended relative to the previous color. This requires incredibly stable impression, precise control over ink transfer, and robust mechanical systems that minimize vibration and drift. In narrow-web printing, where the web width is typically less than 20 inches, these factors become even more pronounced. The smaller the substrate, the more visible any registration error becomes.

The Impact of Ink Curing on Registration

The way ink cures or dries is a pivotal factor influencing registration accuracy. In conventional flexo, methods like hot air drying or the use of solvent-based inks present unique challenges. Solvent evaporation can cause the substrate to expand or contract slightly, especially with certain materials, subtly shifting the printed image over time. Hot air drying can also introduce heat, which can affect the dimensional stability of both the ink and the substrate. This means that even if the press is set perfectly at the start, the print may drift out of register as the run progresses.

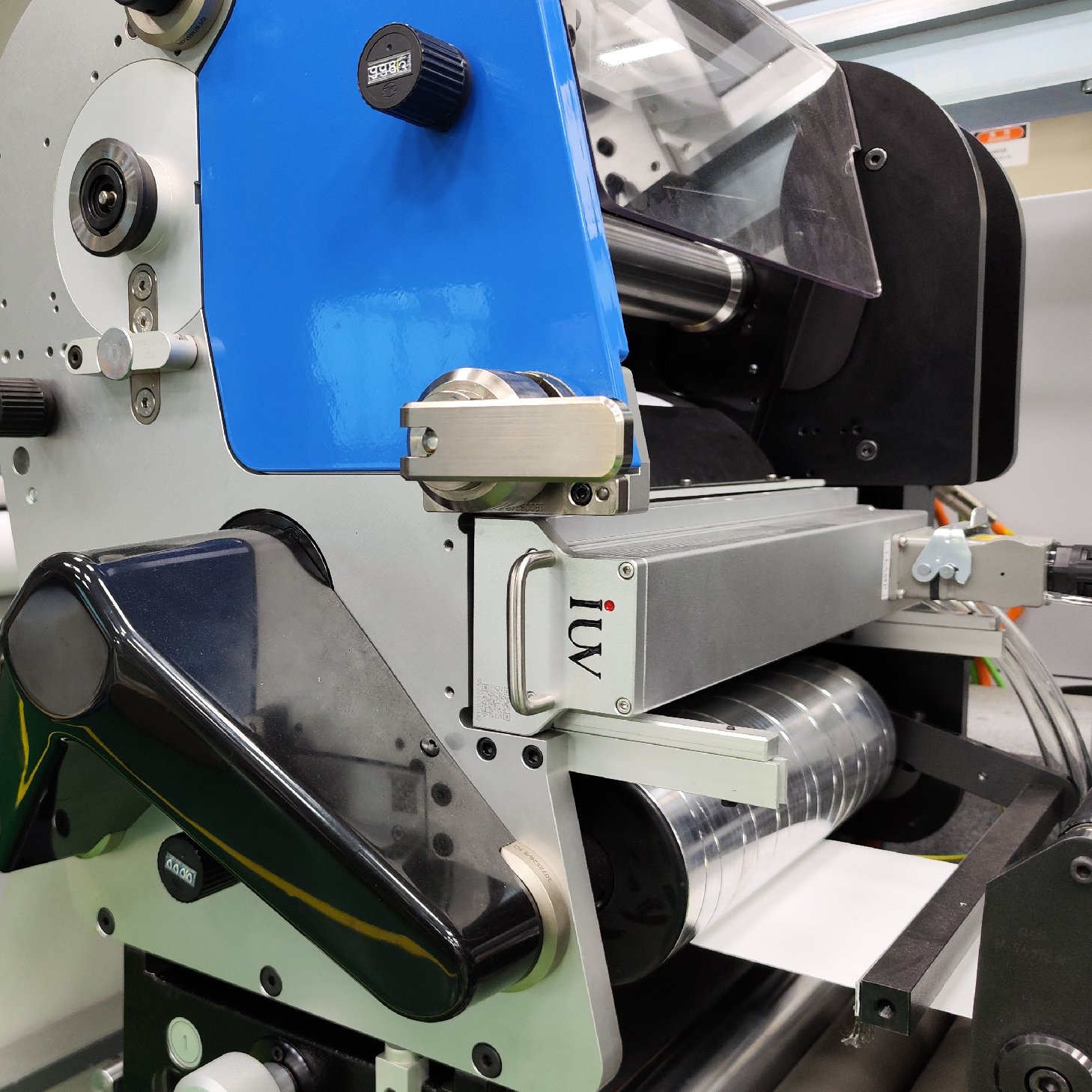

Introducing LED UV Curing: A Game Changer

The advent of UV curing technology revolutionized many printing processes, and its application in narrow-web flexo has been particularly transformative. UV curable inks are photo-initiated; they harden almost instantaneously when exposed to specific wavelengths of ultraviolet light. This rapid, on-demand curing process offers several advantages over traditional methods.

How LED UV Curing Enhances Registration Accuracy

The primary mechanism through which LED UV curing improves registration accuracy lies in its speed and the absence of heat and solvent-related issues.

- Instant Curing: As soon as the ink passes under the LED UV lamp, it cures. There is no waiting period for solvents to evaporate or heat to dissipate. This means the ink is locked in place immediately after application, preventing any post-print movement that could affect subsequent colors.

- No Substrate Distortion: Unlike solvent evaporation or hot air drying, LED UV curing does not introduce significant heat or volatile organic compounds (VOCs) that can cause the substrate to swell, shrink, or warp. The substrate remains dimensionally stable throughout the printing process, providing a consistent platform for each color station.

- Reduced Ink Migration: The instantaneous curing solidifies the ink layer, minimizing the potential for ink to migrate or “ghost” onto adjacent areas or subsequent rollers. This is crucial for maintaining sharp dot definition and preventing color contamination.

- Consistent Ink Film: LED UV inks, when cured properly, form a robust and consistent ink film. This consistency contributes to predictable ink transfer from the anilox roll to the plate and then to the substrate, which is fundamental for accurate color reproduction and registration.

Waste Reduction: A Direct Benefit of Improved Accuracy

The link between improved registration accuracy and waste reduction is direct and significant.

- Fewer Make-Ready Sheets: Achieving perfect registration during press setup (make-ready) is often a time-consuming process that consumes a considerable amount of substrate. When a press consistently achieves excellent registration from the outset, the number of sheets or meters of substrate required to fine-tune the setup is drastically reduced.

- Reduced Scrap: During the production run, any deviation from perfect registration leads to waste. Labels or packaging that are misregistered are typically discarded. Enhanced accuracy means fewer such instances, leading to a substantial decrease in scrap material. This not only saves on material costs but also reduces the volume of waste that needs to be managed.

- Faster Production Speeds: While accuracy is key, speed is also a critical factor in profitability. The ability of LED UV systems to cure instantly allows presses to run at higher speeds without sacrificing registration quality. This means more product can be produced in less time, further improving overall efficiency and reducing the relative waste per unit produced.

- Minimizing Rework: Misregistered prints often require reprints, which essentially doubles the material and labor costs for that batch. Improved accuracy minimizes the need for reprints, preventing this costly scenario.

The Technology Behind Narrow-Web LED Flexo Systems

Modern narrow-web flexo presses equipped with LED UV curing systems are marvels of engineering. They incorporate advanced features designed to optimize every aspect of the printing process:

- Automated Register Control: Many presses now feature sophisticated closed-loop register control systems. These systems use high-speed cameras to monitor the print as it progresses and make micro-adjustments to the impression cylinder or web tension in real-time to maintain perfect registration. LED UV’s instant cure ensures that what the camera sees is the final printed image, not something that will shift later.

- Precise Tension Control: Maintaining consistent web tension is critical for preventing plate and substrate movement. Advanced tension control systems ensure the substrate is held taut and stable, providing an ideal canvas for accurate printing.

- High-Quality Anilox Rolls and Plates: The precision of the anilox roll (which meters ink to the plate) and the quality of the flexographic plate itself are fundamental. Modern systems utilize advanced engraving techniques for anilox rolls and high-resolution photopolymer plates, contributing to sharper images and more predictable ink transfer.

- Optimized LED Lamp Placement: The placement and intensity of the LED UV lamps are crucial. They are typically positioned immediately after each print station, ensuring that the ink is cured precisely at the point of transfer, maximizing the benefits for registration. The specific wavelengths emitted by LED lamps are also optimized for the curing characteristics of UV inks.

Environmental Benefits Beyond Waste Reduction

While waste reduction is a major advantage, narrow-web LED UV flexo systems offer further environmental benefits:

- Energy Efficiency: Compared to traditional mercury vapor UV lamps, LED lamps are significantly more energy-efficient. They consume less power and have a much longer lifespan, reducing the overall carbon footprint of the printing operation.

- No VOC Emissions: The use of UV curable inks eliminates the need for solvents, meaning no VOCs are released into the atmosphere. This contributes to cleaner air and a safer working environment for employees.

- Reduced Hazardous Waste: Traditional solvent-based inks and cleaning agents can contribute to hazardous waste streams. UV curable inks and the reduced need for extensive cleaning chemicals lead to less hazardous waste generation.

Conclusion: A Smart Investment for Label Printers

For narrow-web flexographic label printers, investing in systems equipped with LED UV curing technology is not just an upgrade; it’s a strategic imperative. The improvements in registration accuracy translate directly into significant reductions in material waste and rework, enhancing profitability. Furthermore, the inherent efficiency and environmental advantages of LED UV curing align with the growing demand for sustainable printing practices. By embracing this technology, label converters can achieve higher quality, reduce costs, and position themselves for success in an increasingly competitive market. The precision and efficiency offered by these advanced systems are transforming what is possible in narrow-web flexo printing.