In the demanding world of label and narrow-web printing, preserving the integrity of the substrate is paramount. Many materials, from delicate films to certain paper stocks, can be easily compromised by the heat generated during conventional printing and curing processes. This heat can lead to warping, shrinkage, discoloration, and a significant reduction in overall print quality. Fortunately, the advent of LED UV curing technology offers a revolutionary solution, providing a gentler, more efficient way to cure inks and coatings without inflicting thermal damage.

Understanding the Heat Challenge in Conventional Curing

Traditional UV curing systems, often using mercury vapor lamps, emit a broad spectrum of light. While effective at initiating the photopolymerization of UV inks and coatings, these lamps also generate a considerable amount of infrared radiation, which translates directly into heat. This radiated heat is absorbed by the substrate passing beneath the lamps.

For sensitive materials, even a small increase in temperature can be detrimental. Imagine a thin plastic film used for cosmetic labels. Excessive heat can cause it to stretch unevenly, leading to registration issues and a distorted final product. Similarly, certain specialty papers might lose their intended texture or exhibit unsightly waviness. In flexographic and offset printing, where high-speed production is the norm, the cumulative heat exposure over a long print run can be substantial. This forces printers to often operate at slower speeds or implement costly cooling systems, impacting productivity and profitability.

The LED UV Advantage: Targeted Curing with Minimal Heat

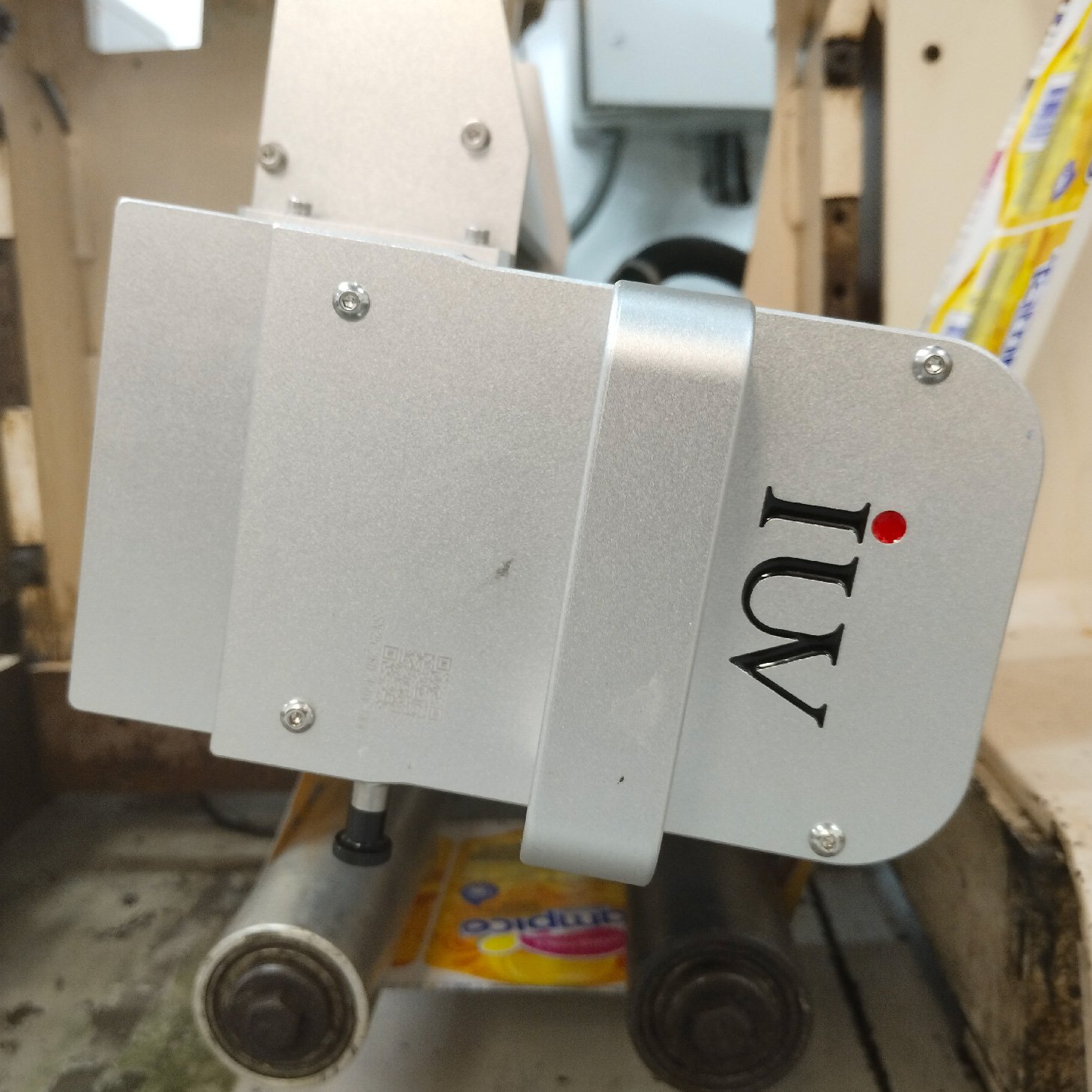

LED UV curing systems operate on a fundamentally different principle. Instead of emitting a broad spectrum of light and significant heat, LEDs deliver highly focused, monochromatic light at specific wavelengths. These wavelengths are precisely chosen to match the absorption peaks of the photoinitiators present in UV-curable inks and coatings.

The key benefit here is efficiency. Nearly all the energy from an LED lamp is converted into useful curing light. Very little energy is wasted as heat. This means that the substrate passing under an LED UV curing unit experiences a dramatically lower thermal load compared to traditional systems.

Benefits for Different Printing Processes

1. Narrow-Web and Label Printing:

The narrow-web sector, heavily reliant on a wide array of substrates, benefits immensely. For applications like shrink sleeves, in-mold labels, and flexible packaging, where films are common, LED UV’s low heat is critical. It prevents premature shrinking or stretching of the film, ensuring precise registration and consistent product appearance. This precision is vital for brand recognition and consumer appeal. Printers can achieve high gloss, vibrant colors, and durable finishes without compromising the film’s dimensional stability.

2. Flexographic Printing:

In flexo, particularly for food packaging and sensitive applications, the ability to cure quickly without overheating the substrate is a significant advantage. Many flexible packaging materials are heat-sensitive. LED UV curing allows flexo printers to maintain high press speeds while ensuring inks are fully cured and adhere properly, even on thin polypropylenes, polyesters, and papers. This reduces the risk of delamination or ink transfer issues.

3. Offset Printing:

While offset printing often uses different ink systems, UV-offset is increasingly popular for high-quality finishes. For label offset printing and commercial applications involving sensitive stocks like textured papers or foils, LED UV offers a gentler alternative. It preserves the unique feel and appearance of these premium materials, preventing unwanted changes in texture or reflectivity that can occur with excessive heat.

4. Specialty Applications:

Beyond mainstream printing, LED UV curing excels in niche areas. For example, printing on textiles, wood, or electronics components often involves heat-sensitive materials. LED UV’s low-temperature curing makes these applications feasible, opening up new market opportunities for print providers. The ability to cure on temperature-sensitive adhesives or varnishes without triggering them prematurely is another significant plus.

Quantifying the Difference: Lower Temperatures, Higher Quality

The difference in heat output between traditional mercury lamps and LED UV systems is substantial. While mercury lamps can raise substrate temperatures significantly, some LED UV systems can cure inks with only a minimal temperature increase – sometimes as little as 5-10°C. This dramatic reduction in thermal impact directly translates to:

- Reduced Warping and Shrinkage: Substrates maintain their original dimensions, crucial for multi-layer constructions and precise die-cutting.

- Preservation of Color Integrity: Sensitive pigments and dyes are less likely to fade or shift hue due to heat exposure.

- Improved Adhesion: Consistent substrate temperature can lead to more uniform ink and coating adhesion.

- Wider Substrate Compatibility: Enables printing on a broader range of delicate and heat-sensitive materials that were previously off-limits.

- Enhanced Productivity: Often, faster curing speeds are achievable without the heat-related risks, boosting throughput.

Beyond Heat: Other Advantages of LED UV

While mitigating heat damage is a primary concern for sensitive substrates, LED UV technology offers a host of other compelling benefits that complement this capability:

- Energy Efficiency: LEDs consume significantly less power than traditional mercury lamps, leading to reduced operational costs and a smaller carbon footprint.

- Longer Lamp Life: LEDs have a much longer lifespan, reducing maintenance downtime and replacement costs.

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs can be switched on and off instantly. This saves energy and reduces the risk of heat buildup during press stops.

- Consistent Output: LEDs provide a stable light output throughout their lifespan, ensuring consistent curing performance.

- Smaller Footprint: LED curing units are generally more compact, which can be a valuable advantage on presses with limited space.

- No Ozone Emission: Mercury lamps produce ozone, which requires ventilation. LEDs do not, simplifying workplace air quality management.

Making the Switch: Considerations for Printers

When considering a transition to LED UV curing for heat-sensitive applications, several factors warrant attention:

- Ink and Coating Formulation: Ensure your chosen inks and coatings are specifically formulated for LED UV curing, with photoinitiators matched to the LED wavelengths.

- Wavelength Selection: Different LED wavelengths (e.g., 365nm, 395nm, 405nm) are suited for different applications and ink types. Consult with your ink supplier.

- Irradiance Levels: Proper irradiance (power density) is essential for achieving full cure. This needs to be matched to the press speed and ink system.

- System Integration: The LED UV system must be compatible with your existing press configuration, considering power requirements and physical space.

Conclusion: A Cooler, Smarter Curing Solution

For printers working with delicate films, specialty papers, and other heat-sensitive materials, the ability of LED UV curing systems to deliver robust curing with minimal heat is transformative. It moves beyond merely drying ink; it offers a precise, controlled process that preserves substrate integrity, enhances print quality, and unlocks new application possibilities. By embracing this advanced technology, print businesses can gain a competitive edge, reduce waste, and meet the increasingly sophisticated demands of their clients in the narrow-web, label, flexo, and offset printing markets. The gentle, efficient power of LED UV is revolutionizing how we print on the most delicate of surfaces.