Synthetic label materials, like polypropylene (PP) and polyethylene (PE) films, offer excellent durability and resistance to chemicals and moisture. These are fantastic qualities for many applications, from product packaging in harsh environments to industrial labeling. However, these smooth, non-porous surfaces present a significant challenge for traditional inks.

Most conventional inks rely on absorption into the substrate to achieve good adhesion. Think about printing on paper – the ink sinks into the fibers, creating a strong mechanical bond. With synthetics, there’s nowhere for the ink to go. The surface energy of these materials is also typically very low. This means ink has a tendency to bead up, leading to poor coverage, weak adhesion, and susceptibility to rubbing or scratching off. This is particularly problematic in demanding applications where labels need to withstand significant wear and tear.

Traditional UV Curing and Its Limitations

For years, conventional UV curing has been the go-to solution for printing on non-absorbent substrates. This technology uses mercury-vapor lamps to emit UV light, which initiates a photochemical reaction in the ink. This reaction causes the ink to polymerize rapidly, forming a solid, cured film on the surface.

While effective, traditional UV curing has some drawbacks. Mercury lamps operate at high temperatures, which can be a concern when printing on heat-sensitive synthetic materials. They also have a limited lifespan and require frequent replacement. Furthermore, the broad spectrum of UV light emitted by these lamps can sometimes lead to over-curing or unwanted reactions with the substrate. Energy consumption is also a significant factor, with these lamps drawing substantial power.

Enter LED UV Curing: A Paradigm Shift

LED UV curing technology represents a significant advancement. Instead of broad-spectrum mercury lamps, LED systems utilize light-emitting diodes (LEDs) that emit UV light within very narrow, specific wavelengths. This precision is key to its enhanced performance, especially concerning ink adhesion on synthetic materials.

The primary wavelengths used in LED UV curing for inks are typically in the UVA range (365 nm, 395 nm, 405 nm). These wavelengths are highly effective at activating the photoinitiators present in UV-curable inks.

How LED UV Curing Enhances Ink Adhesion

The enhancement of ink adhesion on synthetic label materials with LED UV curing can be attributed to several key factors:

- Optimized Wavelengths for Photoinitiator Activation: UV-curable inks contain photoinitiators that absorb UV light and generate free radicals. These radicals then initiate the polymerization process, cross-linking the ink monomers and oligomers into a solid film. LED systems can be precisely tuned to emit wavelengths that perfectly match the absorption spectra of specific photoinitiators. This leads to a much more efficient and complete curing process compared to the broader spectrum of mercury lamps. A more thorough cure means a more robust polymer network is formed, which directly translates to better adhesion.

- Reduced Thermal Stress on Substrates: One of the most significant advantages of LED UV curing is its significantly lower heat output compared to mercury lamps. Mercury lamps generate a considerable amount of infrared (IR) radiation, which is essentially heat. This heat can warp, shrink, or otherwise damage sensitive synthetic label materials, especially thin films. LED UV systems emit very little heat, allowing for printing on a wider range of delicate synthetic substrates without compromising their integrity. This ability to maintain substrate stability is crucial for consistent ink laydown and adhesion.

- Surface Energy Modification (Potential): While the primary mechanism is through ink polymerization, there’s an ongoing area of research into whether specific UV wavelengths can subtly alter the surface energy of synthetic materials. Some studies suggest that high-intensity UV exposure, even at specific wavelengths, can indeed increase the surface energy of certain plastics. A higher surface energy generally promotes better wetting and adhesion of inks. While this might not be the sole or primary driver of improved adhesion for all synthetics, it’s a contributing factor that warrants consideration, particularly with advanced ink formulations designed to leverage this effect.

- Efficient Curing for a Dense Polymer Network: The efficiency of LED curing ensures that the ink polymerizes thoroughly and rapidly. This creates a dense, highly cross-linked polymer film. A well-formed polymer film adheres better to the substrate because it creates stronger intermolecular forces between the ink and the material’s surface. Incomplete curing, which can happen with less efficient systems or when the ink doesn’t “see” the right wavelengths, results in a weaker, less cohesive ink film that is more prone to delamination.

- Formulation Compatibility: The precise wavelengths emitted by LED systems allow ink manufacturers to develop specialized UV ink formulations. These formulations can be optimized to react most effectively with LED energy. This means inks can be designed with specific photoinitiators that are highly sensitive to 365nm or 395nm light, leading to faster cure speeds and superior adhesion properties tailored for synthetic substrates.

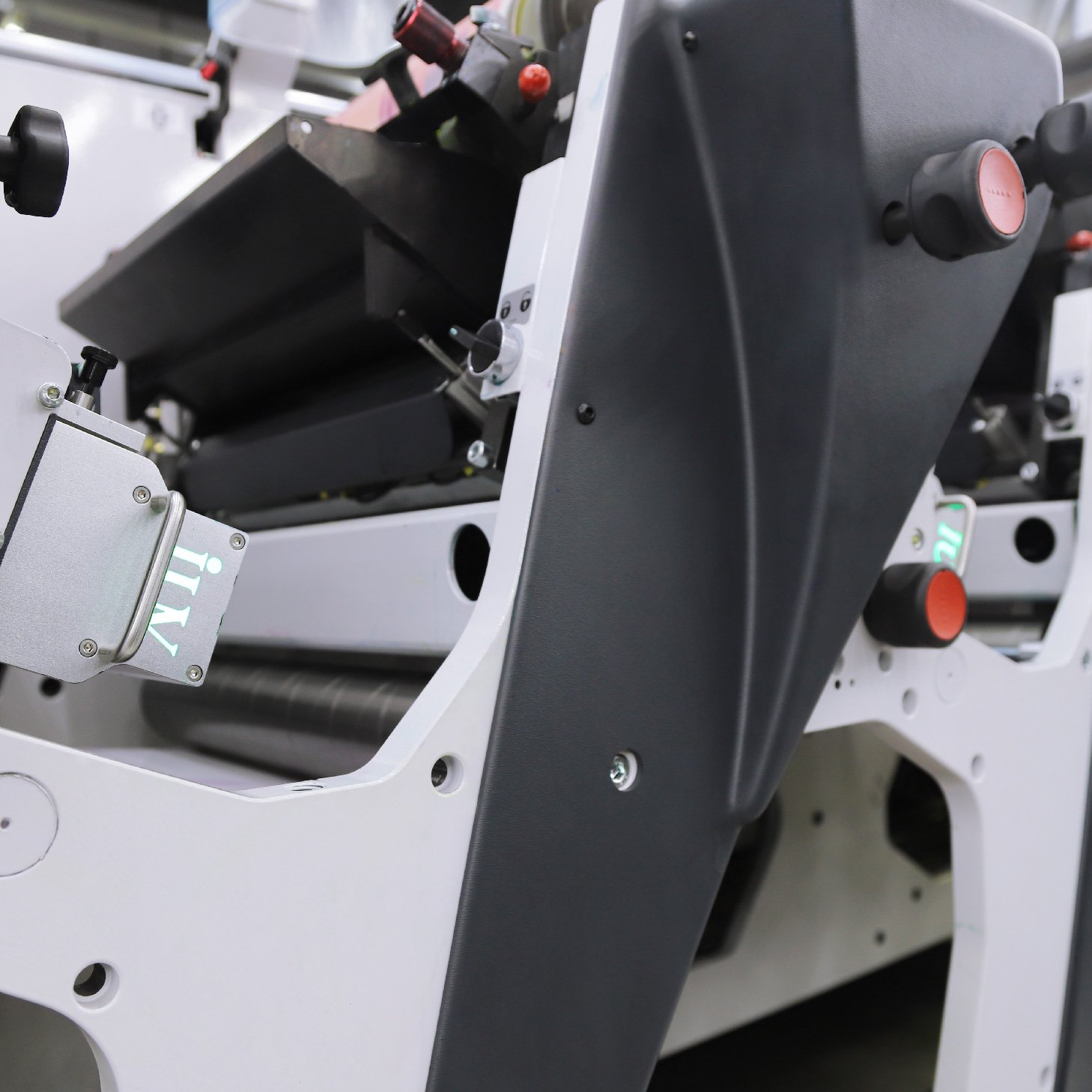

Applications in Narrow Web Printing

The benefits of LED UV curing are particularly evident in the narrow web printing sector, which is dominated by label and flexible packaging production. Many of these applications utilize synthetic materials like BOPP (biaxially oriented polypropylene), PET (polyethylene terephthalate), and PE.

- Flexographic Printing: In flexo, where ink transfer relies on raised image plates, consistent ink transfer and adhesion are paramount. LED UV curing ensures that the ink cures quickly and effectively as it leaves the anilox roll and transfer to the substrate. This is vital for maintaining sharp print definition and preventing ink from smearing or lifting, especially on smooth synthetic surfaces. The speed of flexo presses means rapid curing is essential, and LEDs excel here.

- Offset (Sheetfed and Web) Printing: While flexo is prominent, offset printing also uses synthetic substrates for labels and packaging. LED UV curing in offset presses allows for immediate handling of printed sheets or webs without the risk of smudging or blocking, even on challenging synthetics. This improves productivity and reduces waste.

- Digital Printing (Inkjet): Many production inkjet systems for labels now employ LED UV curing. This is critical because inkjet inks are deposited in fine droplets. For these droplets to form a cohesive, durable print on synthetics, rapid and thorough curing is essential. LED curing’s efficiency ensures that the ink cures before it can spread or be disturbed, leading to excellent adhesion and print quality.

Considerations for Optimal Adhesion

To maximize the benefits of LED UV curing for ink adhesion on synthetic labels, several factors should be considered:

- Substrate Preparation: While not always necessary, sometimes a surface corona treatment or flame treatment can be applied to synthetic materials to increase their surface energy. This pre-treatment can significantly improve ink wetting and subsequent adhesion, complementing the curing process.

- Ink Formulation: Choose UV inks specifically designed for synthetic substrates and compatible with LED UV curing systems. These inks will contain photoinitiators optimized for the wavelengths provided by your LED lamps and may include adhesion promoters.

- Wavelength and Intensity: Ensure your LED UV curing system emits wavelengths that effectively cure your chosen ink and provides sufficient intensity (irradiance) and dosage (energy per unit area) for a complete cure at your press speeds.

- Press Speed and Exposure Time: Matching the press speed to the curing capability of the LED system is crucial. Longer exposure times (at slower speeds) generally lead to better cures, but modern LED systems are very powerful and can cure inks at high speeds.

The Future of Synthetic Label Printing

The trend towards more durable, resistant, and aesthetically pleasing labels means synthetic materials will continue to grow in popularity. LED UV curing is not just an improvement; it’s becoming the standard for achieving high-quality, durable prints on these challenging substrates. Its energy efficiency, reduced heat, precise control, and compatibility with advanced ink formulations make it an indispensable technology for label printers looking to excel in demanding markets. The enhanced ink adhesion it provides means labels look better for longer, perform reliably in their intended environments, and meet the evolving needs of brand owners and consumers alike.