The world of narrow web printing, encompassing labels, flexible packaging, and specialty applications, is a vibrant ecosystem where color accuracy and visual impact are paramount. In this competitive landscape, achieving superior color saturation isn’t just a desirable trait; it’s a critical differentiator. Traditional printing methods have long grappled with limitations in color vibrancy, often sacrificing saturation for speed or material compatibility. However, the advent and refinement of LED UV curing technology have presented a powerful solution, fundamentally transforming how printers approach color fidelity in both offset and flexographic processes. This technology doesn’t merely dry ink; it actively contributes to a richer, more luminous color output that captures attention and elevates brand perception.

Understanding the Fundamentals: Ink, Light, and Color

At its core, color in printing is a matter of light absorption and reflection. Pigments within inks absorb certain wavelengths of light and reflect others. The reflected wavelengths are what our eyes perceive as color. For a color to appear saturated, it needs to reflect a pure, intense hue, absorbing as much of the other wavelengths as possible. Achieving this pure reflection is influenced by several factors, including the quality of the pigments, the ink film thickness, and importantly, how the ink solidifies or cures.

Traditional drying methods, like heat or exposure to broad-spectrum UV lamps, can sometimes compromise the integrity of the ink film or the pigments themselves. Heat can lead to ink spread or a reduction in pigment density. Older UV technologies, while faster than heat, often emitted a spectrum of light that could cause unwanted chemical reactions or inefficient curing, resulting in a less defined ink layer and, consequently, diminished color saturation.

The LED UV Revolution: A Targeted Approach to Curing

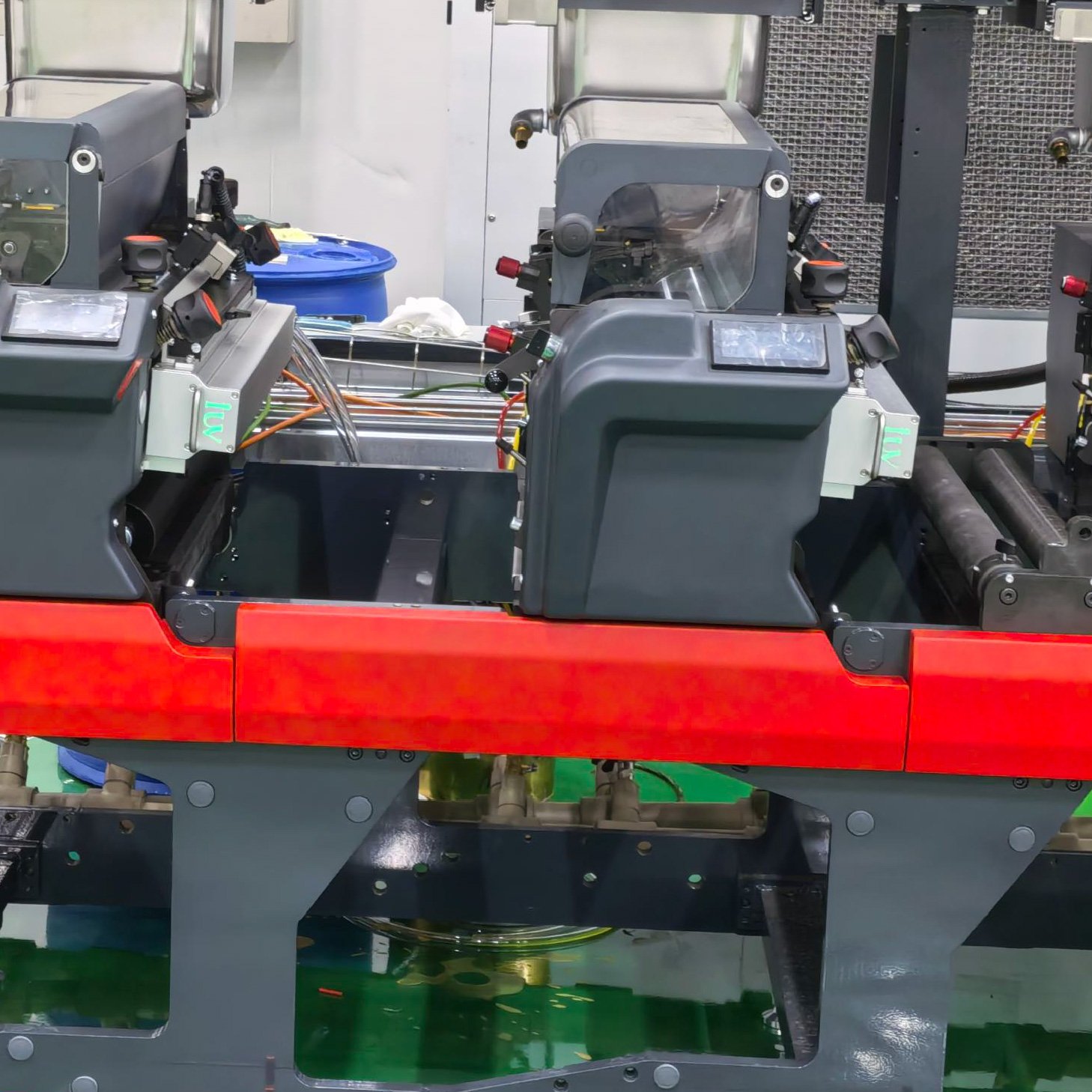

LED UV curing represents a paradigm shift. Instead of relying on broad-spectrum mercury lamps that emit a wide range of light wavelengths, including heat-generating infrared, LED UV systems utilize highly efficient Light Emitting Diodes (LEDs). These LEDs emit a very specific, narrow band of ultraviolet light, precisely matched to the photoinitiators within UV-curable inks and coatings.

This targeted approach offers several critical advantages that directly impact color saturation. Firstly, LED UV systems generate significantly less heat than traditional UV lamps. This reduced thermal load prevents the ink from spreading or “blooming” during the curing process. An ink film that remains precisely where it was applied, with sharp edges and consistent thickness, is far more capable of reflecting pure color wavelengths. The pigments are held in their optimal position, maximizing their light-absorbing and reflecting properties.

Secondly, the precise wavelength emission of LEDs ensures a more efficient and complete cure. Photoinitiators absorb the specific UV light and initiate a rapid polymerization process, transforming the liquid ink into a solid, cross-linked polymer film almost instantaneously. This thorough curing creates a robust, stable ink layer. This stability means the colorants are locked in, preventing any settling or migration that could dull the perceived vibrancy over time. The result is an ink film that consistently delivers the intended color intensity.

Enhancing Saturation in Offset Printing: Precision Meets Power

In narrow web offset printing, where fine detail and consistent ink laydown are crucial for labels and high-quality graphics, LED UV curing offers a compelling upgrade. Offset printing relies on a precise transfer of ink from a plate to a blanket, and then to the substrate. Maintaining the integrity of that ink film during drying is key to achieving sharp dots and smooth color transitions.

With LED UV, printers can achieve faster press speeds without sacrificing ink quality. The instantaneous cure means ink is immediately stable, allowing for faster subsequent print stations or finishing processes. More importantly, the reduced heat from the LEDs prevents the ink from being re-emitted into the air or spreading on the substrate, which can happen with heat-set drying. This controlled curing process preserves the density of the pigment in the ink film. Imagine laying down a layer of vibrant red ink. If the curing process is too hot or inefficient, some of the pigments might not be fully encapsulated or could migrate. LED UV locks them down precisely where they are meant to be, ensuring every particle contributes to the rich, deep red hue. This leads to colors that appear deeper, more luminous, and significantly more saturated than what can be achieved with conventional drying methods in offset.

Boosting Vibrancy in Flexographic Printing: Flexibility and Fidelity

Flexography, the workhorse of the label and flexible packaging industry, benefits immensely from LED UV curing’s ability to handle a wide range of substrates, including films and foils that are sensitive to heat. The inherent flexibility of the flexo printing process, with its raised image carrier, demands inks that cure rapidly and adhere well.

LED UV curing is particularly well-suited for flexo. The high intensity of LED light ensures rapid curing even on challenging, non-porous substrates where ink might otherwise struggle to dry. This rapid solidification prevents ink from spreading, which is a common issue in flexo that can lead to muddy colors or loss of fine detail. For narrow web flexo applications where brand colors need to be replicated precisely and vibrantly, LED UV allows for a greater intensity of color without the risk of smudging or poor ink transfer.

Consider printing a bright yellow or a deep blue on a clear film. With traditional drying, the ink might appear thin or lack depth due to incomplete curing or spreading. LED UV, by providing a powerful, targeted cure, ensures that the ink film is dense and uniformly applied. This allows the pigments to perform at their maximum potential, absorbing unwanted light wavelengths and reflecting the intended color with exceptional purity and saturation. The ability to achieve such vibrant results on a variety of flexible substrates opens up new design possibilities for brand owners and printers alike.

Beyond Color: Additional Advantages of LED UV in Narrow Web

The impact of LED UV curing extends beyond just enhanced color saturation. Printers also benefit from:

- Reduced Energy Consumption: LEDs are significantly more energy-efficient than traditional mercury lamps, leading to lower operating costs and a smaller environmental footprint.

- Longer Lamp Lifespan: LEDs have an operational life of tens of thousands of hours, drastically reducing downtime and replacement costs associated with traditional UV lamps.

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs can be switched on and off instantaneously. This is ideal for intermittent printing operations and further contributes to energy savings.

- Improved Working Environment: The absence of ozone generation and significantly reduced heat output create a safer and more comfortable working environment for press operators.

- Wider Substrate Compatibility: The low heat output allows for printing on a broader range of heat-sensitive materials, including thin films and delicate plastics, without distortion or damage.

The Future is Vivid: Embracing LED UV for Superior Print Quality

In the fast-paced world of narrow web printing, the demand for visually striking labels and packaging is ever-increasing. Brands need their products to stand out on the shelf, and color saturation plays a pivotal role in achieving that goal. LED UV curing technology offers a tangible, powerful solution for offset and flexographic printers looking to elevate their print quality. By providing a controlled, efficient, and cool curing process, LED UV ensures that inks are applied and solidified in a manner that maximizes pigment performance. This translates directly into deeper, richer, and more vibrant colors. For printers aiming to deliver unparalleled visual impact and meet the exacting standards of today’s brands, adopting LED UV curing is not just an upgrade; it’s an investment in a brighter, more colorful future. The enhanced color saturation achieved through this technology is a testament to how precise engineering can unlock the full potential of printing inks, creating results that truly shine.