LED curing systems are revolutionizing narrow web printing. This technology offers significant advantages over traditional methods. It’s a game-changer for label printing and beyond.

Traditional UV curing systems use mercury lamps. These lamps generate a lot of heat. They also consume more energy. Mercury lamps have a shorter lifespan. They require frequent replacement. This adds to operational costs.

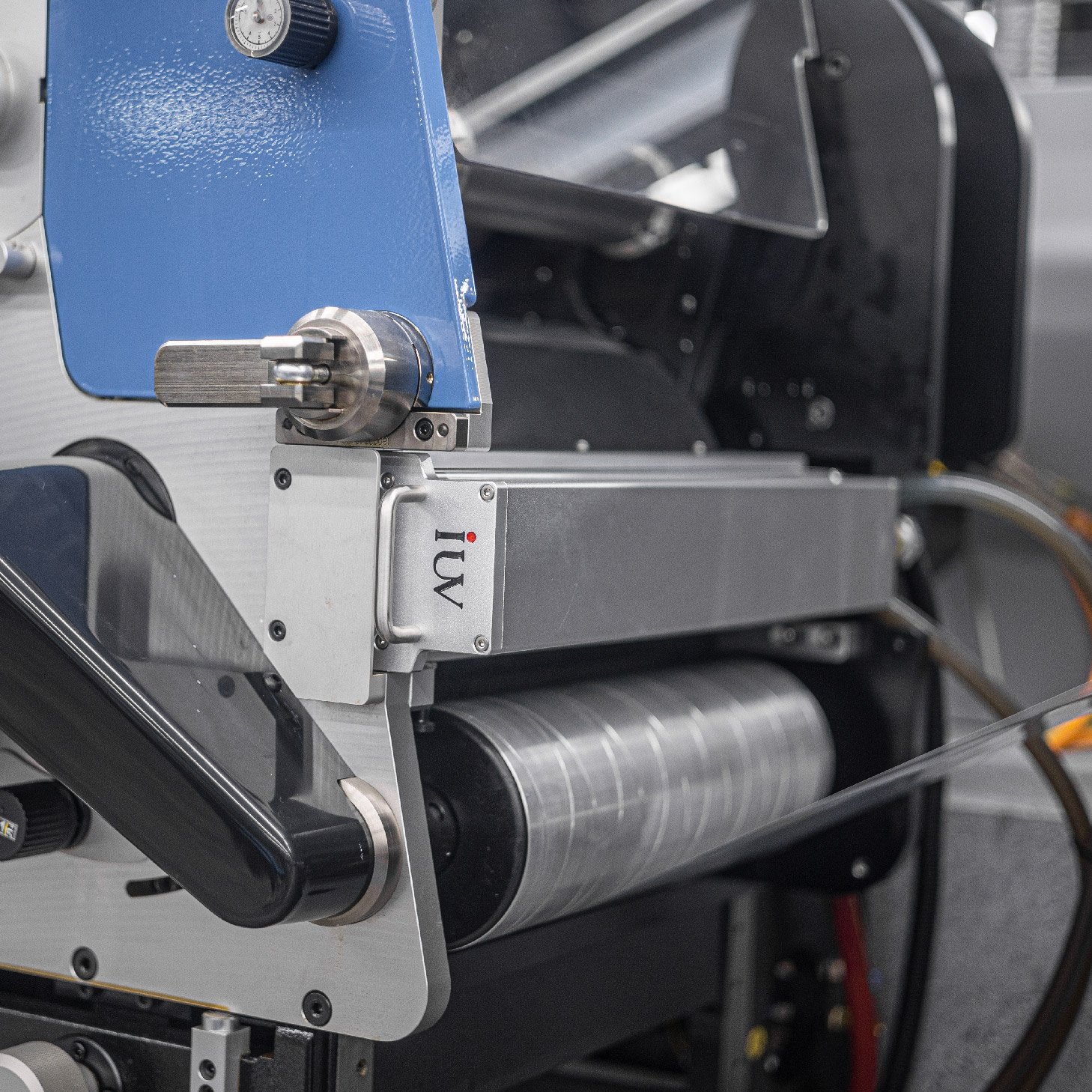

LED UV curing systems use light-emitting diodes. These diodes produce UV light at specific wavelengths. This targeted wavelength is highly efficient. It cures inks and coatings quickly and effectively.

One of the biggest benefits is energy efficiency. LED systems use much less power. They can reduce energy consumption by up to 70%. This translates to substantial cost savings. It also lowers the carbon footprint of the printing operation.

Heat management is another major advantage. LED curing generates very little heat. This is crucial for narrow web printing. Many label substrates are heat-sensitive. Think of thin films and certain plastics. Traditional lamps can warp or damage these materials. LED systems prevent this damage. They allow for printing on a wider range of substrates. This opens up new possibilities for label designers and manufacturers.

The lifespan of LED lamps is also impressive. They can last for 20,000 to 50,000 hours. This is significantly longer than mercury lamps. It means less downtime for lamp replacement. It also reduces maintenance costs and labor.

Faster curing speeds are another key benefit. LED systems can cure inks almost instantly. This allows for faster printing speeds on the press. High-speed narrow web presses can operate at their maximum potential. This increases productivity and throughput. It helps printers meet tight deadlines.

LED UV curing technology offers excellent print quality. The precise wavelength of light ensures thorough curing. This results in sharper images and more vibrant colors. It improves the durability of the printed labels. Resistance to abrasion, chemicals, and fading is enhanced. This is vital for labels that need to withstand harsh environments.

The environmental benefits are also noteworthy. LED systems do not contain mercury. This eliminates the hazard associated with mercury disposal. The lower energy consumption also contributes to a greener printing process. This aligns with growing consumer and regulatory demand for sustainable practices.

Integration into existing narrow web presses is often straightforward. Many manufacturers offer retrofit kits. This allows printers to upgrade their current equipment without a complete overhaul. This makes the transition to LED technology more accessible.

Flexographic printing is a primary beneficiary. Narrow web flexo presses are common for label production. These presses benefit greatly from the speed and efficiency of LED curing. It allows for shorter print runs to be economically viable. This is important in today’s market. Customization and personalization of labels are increasing.

Offset printing, particularly in the narrow web sector, also sees benefits. LED curing can improve the print quality and durability of offset labels. It provides a consistent cure across the entire print area.

The precise control offered by LED systems is also valuable. The intensity of the UV light can be adjusted. This allows printers to fine-tune the curing process for different inks and substrates. This level of control leads to more consistent results. It reduces waste and material spoilage.

The future of narrow web printing is undoubtedly linked to LED curing. The technology continues to evolve. Newer, more powerful LED systems are emerging. They offer even faster curing speeds and broader spectral outputs. This will further expand the capabilities of narrow web printing.

Consider the application of these advanced labels. They are used in pharmaceuticals, food and beverage, cosmetics, and industrial markets. Each requires specific performance characteristics. LED curing helps meet these diverse demands. For instance, food-grade labels need to be durable and safe. Pharmaceutical labels may require resistance to sterilization processes. Industrial labels often need to withstand extreme conditions.

The return on investment for LED curing systems can be quite attractive. While the initial cost may be higher than traditional systems, the long-term savings in energy, maintenance, and increased productivity quickly offset this.

The versatility of LED curing is a significant factor. It is compatible with a wide array of UV-curable inks, varnishes, and coatings. This includes standard UV inks, water-based UV inks, and special effect coatings. The narrow web sector relies heavily on these varied consumables.

In summary, LED curing systems offer a compelling package of benefits for narrow web printing. They deliver energy efficiency, reduced heat, extended lamp life, faster speeds, superior print quality, and environmental advantages. These factors combine to make LED technology an indispensable tool for modern label printers. The transition to LED is not just an upgrade; it’s a strategic move towards a more competitive and sustainable future in narrow web printing.

The evolution of narrow web printing hinges on embracing innovative solutions. LED UV curing stands at the forefront of this innovation. Its impact on efficiency and quality is undeniable. Printers looking to stay ahead will find this technology to be a vital component of their operations. The consistent performance and reliability of LED systems ensure that labels produced are not only visually appealing but also highly functional and durable. This technological leap forward empowers businesses to create better products and serve their customers more effectively.