How LED Curing Systems Support VOC-Free Printing Environments

In recent years, the printing industry has made significant strides in reducing its environmental impact. One of the most promising developments is the adoption of LED curing systems, which have proven to be highly effective in promoting VOC-free printing environments. These systems offer an efficient, eco-friendly solution for printing technologies such as label printing, flexographic printing, letterpress printing, and narrow-web printing. By utilizing ultraviolet (UV) light to cure inks instantly, LED curing systems provide a fast and sustainable alternative to traditional solvent-based drying methods.

The Challenge of VOCs in Printing

Volatile organic compounds (VOCs) are chemicals commonly found in inks, coatings, and cleaning solvents used in the printing industry. These compounds, when released into the air during the printing process, contribute to air pollution and pose significant health risks to workers. Traditional printing methods, particularly those involving solvent-based inks, rely on evaporation to dry the inks. This process releases VOCs into the environment, creating not only health hazards but also environmental concerns.

In response to these challenges, the industry has increasingly turned to LED UV curing technology. LED curing systems offer a more sustainable approach, significantly reducing or even eliminating VOC emissions.

How LED UV Curing Works

LED UV curing is a process in which inks or coatings are exposed to ultraviolet light emitted by LED lamps. Unlike traditional mercury vapor lamps, which require significant energy to operate and emit large amounts of heat, LED UV lamps are energy-efficient and generate minimal heat. When exposed to the UV light, the ink undergoes a photochemical reaction that causes it to solidify almost instantly. This rapid curing process means that inks and coatings are dry and ready for further processing in a fraction of the time compared to conventional drying methods.

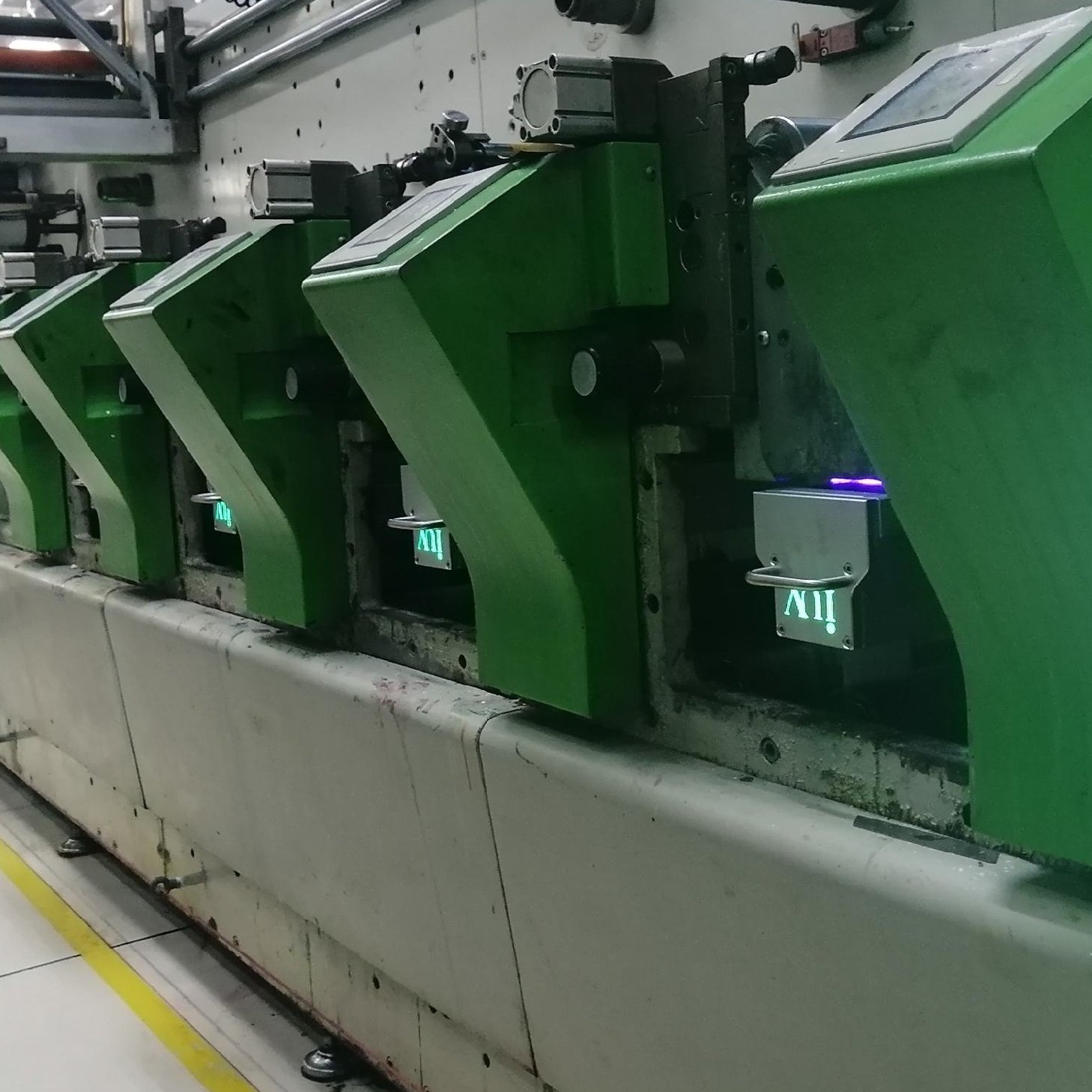

LED Curing in Narrow-Web and Label Printing

Label printing and narrow-web printing are among the industries that have greatly benefited from LED curing systems. In narrow-web printing, which is commonly used for flexible packaging, labels, and tags, efficiency and speed are crucial. LED UV curing provides a solution that enhances throughput while minimizing energy consumption and VOC emissions. The instant curing process allows printers to quickly move from one job to the next, improving overall productivity.

Additionally, LED curing systems in label printing often result in higher-quality prints with better color vibrancy and greater durability. The lack of solvents in LED-cured inks means there are fewer risks of contamination or quality degradation, which is particularly important in food packaging and other sensitive applications.

Flexographic Printing and Its Environmental Benefits

Flexographic printing, a widely used method for packaging and label production, also stands to benefit greatly from LED UV curing technology. Flexo printing typically uses fast-drying solvent-based inks, which release VOCs as they evaporate. Switching to LED UV curing inks eliminates this issue, as the inks cure through exposure to UV light rather than evaporation.

LED curing systems in flexographic printing also offer the benefit of faster production cycles. The reduced drying time allows for higher print speeds, leading to a more efficient workflow. Furthermore, the lower energy requirements of LED UV lamps result in reduced operating costs and a smaller environmental footprint.

Letterpress Printing and VOC-Free Solutions

Letterpress printing, though less commonly used today, remains an important method for specialty and high-quality print jobs, such as premium stationery and invitations. Like other traditional printing methods, letterpress printing often relied on solvent-based inks that emitted harmful VOCs. LED curing technology offers an alternative that supports a cleaner, safer, and more environmentally-friendly printing process.

LED UV systems can be integrated into letterpress presses to cure inks instantly, cutting down on the drying time while significantly reducing the need for volatile chemicals. This shift not only improves worker safety but also opens up new possibilities for more sustainable production practices in letterpress printing.

Key Advantages of LED Curing for VOC-Free Printing

- Reduced VOC Emissions: The most significant benefit of LED curing systems is the reduction, or elimination, of VOCs. By curing inks without the need for solvents, these systems contribute to cleaner air in printing facilities and minimize harmful emissions.

- Energy Efficiency: LED UV curing systems are far more energy-efficient than their mercury vapor counterparts. They consume less power and generate less heat, reducing overall energy usage and associated costs. This energy efficiency is particularly beneficial for high-volume printing operations where large amounts of energy are typically required.

- Faster Curing Times: LED UV curing is known for its speed. In traditional printing, drying times can delay production. With LED curing, inks dry almost instantly, allowing for faster turnaround times and higher production rates. This is particularly advantageous in industries like packaging, where quick production cycles are essential.

- Enhanced Print Quality: LED-cured inks tend to exhibit superior adhesion and durability, resulting in prints that are more resistant to wear and tear. This makes LED curing an ideal choice for products that require high durability, such as labels that will endure exposure to moisture or sunlight.

- Lower Operating Costs: Although the initial investment in LED curing equipment can be higher than traditional methods, the long-term savings are significant. LED lamps last longer, require less maintenance, and use less energy, all of which contribute to reduced operating costs.

- No Heat Damage: Unlike traditional UV lamps, LED lamps emit very little heat. This makes them ideal for printing on heat-sensitive substrates like films or thin papers that might warp or degrade with conventional UV curing.

Conclusion: A Cleaner, Greener Future for Printing

As the printing industry continues to evolve, LED UV curing technology represents a vital step forward in creating cleaner, greener, and more efficient printing processes. By eliminating the need for VOC-emitting solvents, these systems contribute significantly to reducing environmental and health risks associated with traditional printing methods.

For industries such as label printing, flexographic printing, and narrow-web printing, the benefits of LED curing are clear: faster production cycles, higher-quality prints, and a commitment to sustainability. As more printers adopt this technology, the shift toward VOC-free environments will help create a safer and more eco-conscious future for the industry.