Accelerating Flexo Printing: The LED Curing Advantage for Ink Drying

In the fast-paced world of label printing, efficiency is king. Flexographic printing, or flexo printing, remains a dominant force, especially in narrow web applications. Speed and quality are paramount. A significant bottleneck in many flexo operations has traditionally been ink drying time. This is where advancements in curing technology, specifically LED UV curing systems, are revolutionizing the process, drastically reducing drying times and boosting overall productivity.

For decades, traditional UV curing systems, often using mercury vapor lamps, were the go-to solution for rapid ink drying in flexo printing. These lamps emit a broad spectrum of UV light, including heat-generating infrared radiation. While effective, they come with significant drawbacks. They consume a considerable amount of energy, have a limited lifespan, and require frequent replacement and disposal of hazardous materials. The heat generated can also be an issue, potentially affecting heat-sensitive substrates or causing unwanted ink transfer.

Enter LED UV curing. Light Emitting Diodes (LEDs) offer a fundamentally different approach to UV curing. Instead of a broad spectrum, LEDs emit a highly specific wavelength of UV light, typically in the UVA range (365nm, 395nm, or 405nm). This targeted emission is crucial for efficient photoinitiator activation within UV-curable inks and coatings. The result is rapid, efficient curing with significantly less heat.

How LED Curing Speeds Up Ink Drying in Flexo

The core of LED UV curing’s advantage lies in its efficiency and targeted energy delivery. Here’s a breakdown:

- Instant On/Off Capability: Unlike mercury lamps that require a warm-up period, LEDs switch on and off instantaneously. This means energy is only used when printing is actively occurring, leading to immediate curing as the ink passes under the LED unit. No waiting, no pre-heating, just instant solid ink.

- Consistent Wavelength Output: LEDs deliver a stable and consistent wavelength output throughout their operational life. This ensures predictable and repeatable curing results, batch after batch. Mercury lamps, on the other hand, can see their spectral output shift over time, leading to less consistent drying and potential quality issues.

- High Irradiance for Fast Curing: Modern LED systems can achieve very high irradiance levels at specific wavelengths. Irradiance is the measure of UV power density. Higher irradiance translates directly to faster chemical reactions within the ink, meaning the ink cures and dries in a fraction of the time compared to older technologies. This is particularly beneficial for high-speed flexo printing presses where every millisecond counts.

- Energy Efficiency: LEDs are remarkably energy-efficient. They convert a much higher percentage of electrical energy into UV light compared to mercury lamps, which waste a significant portion as heat. This energy saving directly contributes to lower operational costs. The reduced heat output also means less energy is needed for cooling the printing press and the environment.

- Reduced Heat on Substrate: The focused wavelength of LEDs generates far less heat than mercury lamps. This is a game-changer for printing on delicate or heat-sensitive substrates, such as thin films, certain plastics, or even some papers. The risk of substrate distortion, shrinkage, or adhesion issues due to excessive heat is dramatically reduced. This allows for greater substrate flexibility and expands the range of printable materials.

- Longer Lifespan and Lower Maintenance: LED systems have an exceptionally long operational lifespan, often exceeding 20,000 hours. This is significantly longer than the typical 1,000-2,000 hours for mercury lamps. The reduced need for lamp replacement translates into less downtime, lower maintenance costs, and less waste from discarded bulbs.

Impact on Flexo Printing Processes

The adoption of LED UV curing systems has profound implications for flexo printing, especially in the narrow web sector where labels and flexible packaging are primary products.

- Increased Press Speeds: The ability to cure ink almost instantaneously allows printers to push their presses to higher speeds without compromising ink drying. This means more labels or packaging produced per hour, directly impacting profitability.

- Improved Print Quality: Consistent curing leads to sharper dot definition, better color vibrancy, and enhanced scratch and chemical resistance. The absence of excessive heat also prevents ink spreading or mottling, ensuring a premium finish.

- Expanded Ink and Coating Options: While traditional UV inks and coatings are compatible, the advancement of LED-specific formulations offers even better performance. These inks are designed to cure optimally under the specific wavelengths and irradiance of LED systems, unlocking new possibilities for specialized finishes and effects.

- Reduced Environmental Impact: The energy savings, absence of mercury (a hazardous material), and longer component lifespan all contribute to a more sustainable printing process. This is increasingly important as brands and consumers demand eco-friendly manufacturing practices.

- Lower Operational Costs: Reduced energy consumption, fewer consumable replacements (lamps), and less downtime for maintenance collectively contribute to a lower cost per printed piece.

Considerations for Implementing LED Curing

While the benefits are substantial, a successful transition to LED UV curing involves careful consideration.

- Ink and Coating Compatibility: Ensure your chosen inks and coatings are formulated for LED curing. While some conventional UV inks may cure, LED-specific formulations offer optimal performance and speed.

- Wavelength Selection: Different LED wavelengths (365nm, 395nm, 405nm) are suited for different ink chemistries. Consult with ink suppliers to determine the best wavelength for your specific application and ink sets.

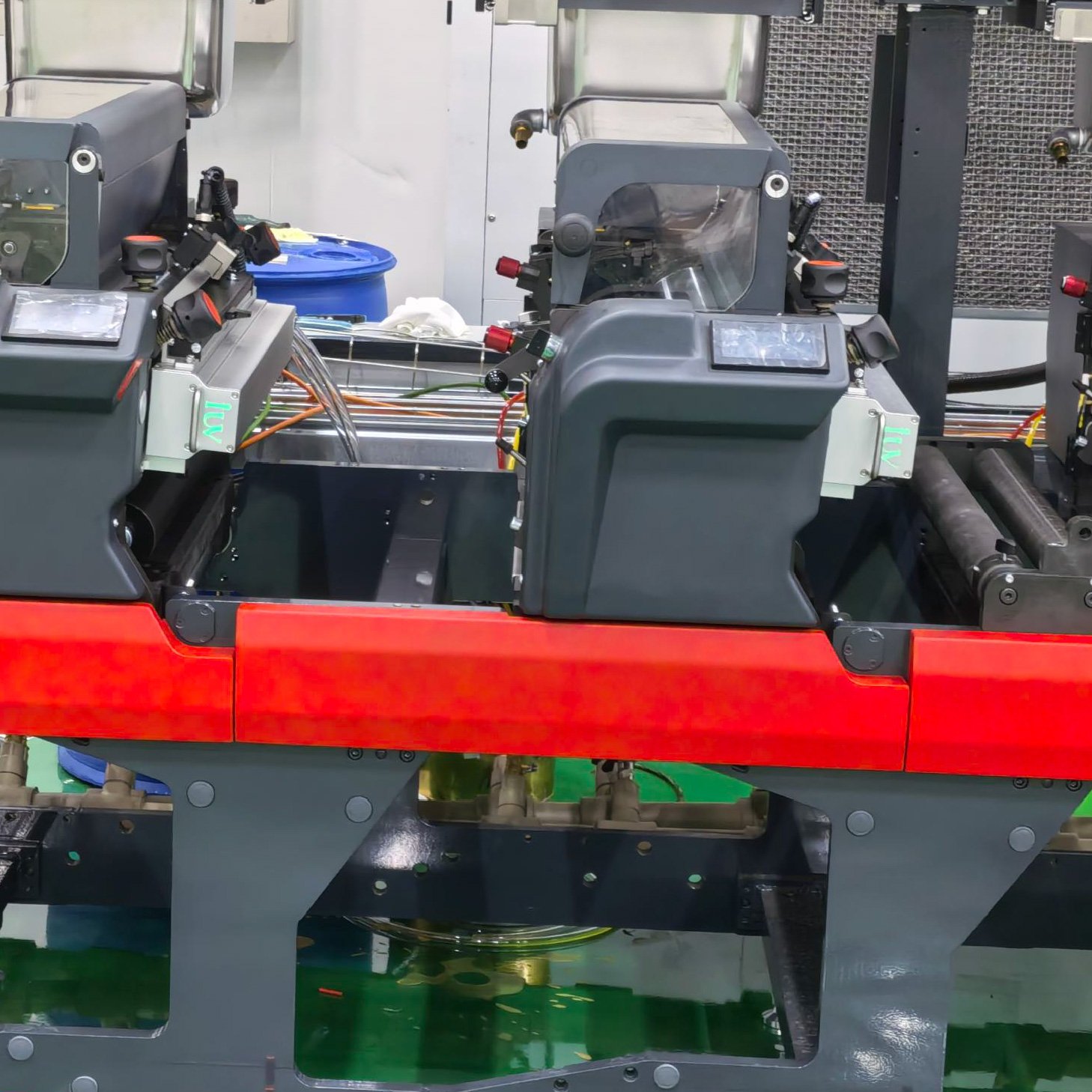

- Press Integration: LED curing units are designed to be integrated into existing flexo presses. The physical size and power requirements of the LED heads need to be considered during installation.

- Initial Investment: The upfront cost of LED UV curing systems can be higher than traditional UV systems. However, the long-term savings in energy, consumables, and increased productivity often provide a strong return on investment.

Conclusion

The shift towards LED UV curing in flexo printing is not just a trend; it’s a technological evolution that delivers tangible benefits. By drastically reducing ink drying times, enhancing print quality, and offering significant operational and environmental advantages, LED curing systems are empowering flexo printers to achieve new levels of efficiency and competitiveness in the demanding label and packaging markets. The speed, precision, and sustainability offered by LED technology are reshaping what’s possible in modern flexographic printing.