Printing has seen rapid changes. Short-run jobs are now common. This demands flexibility and speed. Consistency is key for these jobs. LED curing systems offer this. They are a game-changer for various printing methods.

The Challenge of Short-Run Printing

Short-run printing presents unique hurdles. Traditional UV curing methods can be inconsistent. They might not heat up quickly enough. This leads to uneven curing. It affects ink adhesion and finish. For label printing, this is a major issue. Labels need to be durable. They must look good.

Flexographic printing often handles short runs. Narrow web presses are used for labels and packaging. Achieving consistent color and cure is vital. If the UV lamps are not stable, the results vary. This means more waste. It also means unhappy clients. Offset printing, or sheetfed printing, also sees short runs. Digital presses have made this easier. But integrating UV curing still needs attention.

Understanding UV Curing Technology

UV curing uses ultraviolet light. It hardens inks and coatings instantly. This process is fast. It uses less energy than heat drying. Traditional UV lamps are mercury-based. They emit a broad spectrum of UV light. They require a warm-up period. Their intensity can fluctuate. This makes consistent results difficult.

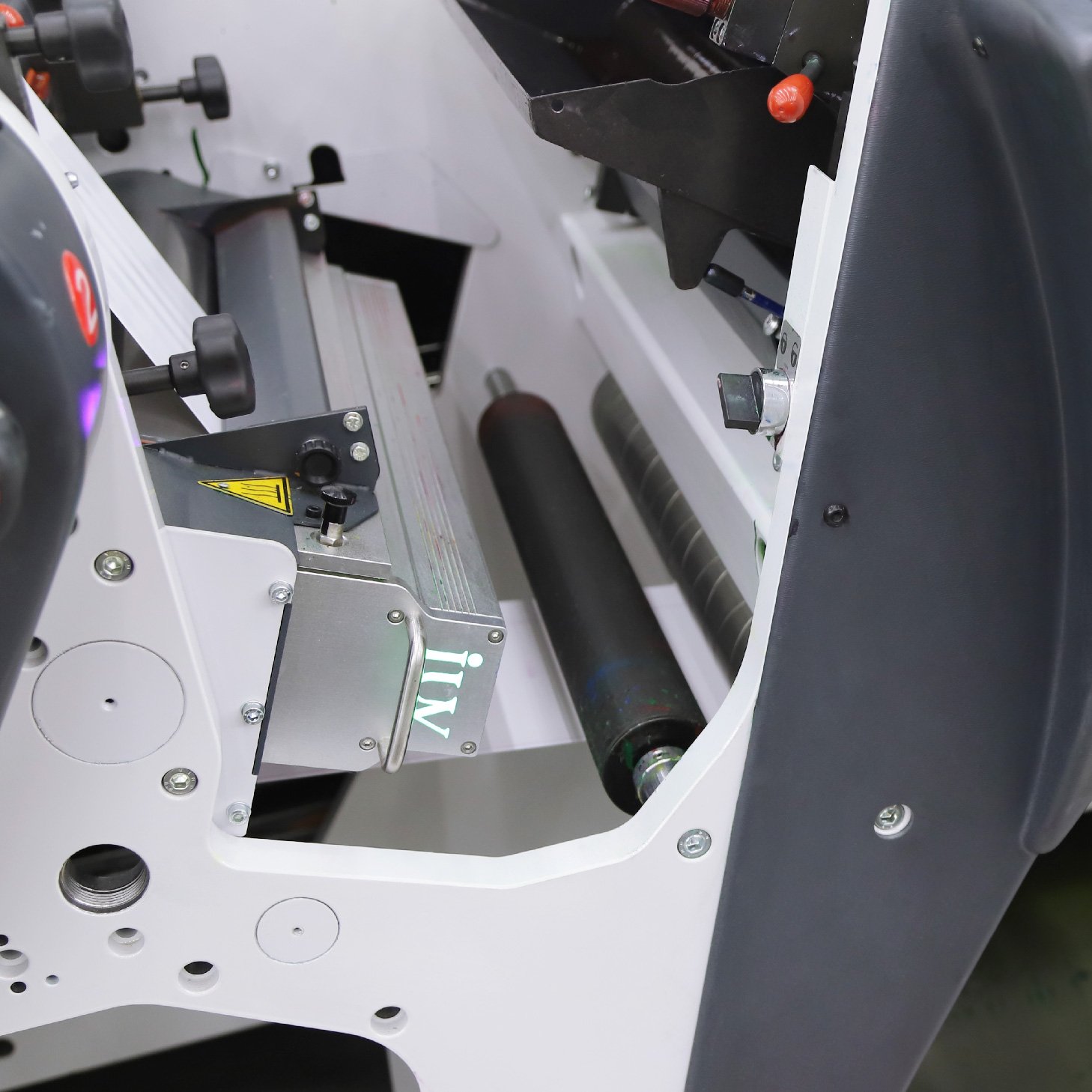

LED curing systems are different. They use Light Emitting Diodes. These diodes emit UV light at specific wavelengths. They reach full intensity immediately. There is no warm-up time. This offers significant advantages.

How LED Curing Ensures Consistency

Consistency is where LED shines. The immediate full power is a big deal. For narrow web flexo printing, this means immediate ink solidification. Each label gets the same treatment. This applies to intricate designs and solid colors alike.

In label printing, this consistency is crucial. Think about brand colors. They must be exact. With LED curing, the ink cures uniformly. This prevents issues like ink tack or smudging. The print quality remains high, job after job.

For narrow web applications, speed and precision matter. LED systems allow presses to run at top speeds. The curing is instant. This reduces the chance of ink transfer. It ensures a sharp, well-defined image.

Sheetfed offset printing also benefits. Short runs are becoming more frequent in this sector. LED curing ensures that the first sheet is as well-cured as the last. This is vital for color accuracy and finish.

Benefits for Different Printing Processes

Narrow Web Flexographic Printing: This is a prime area for LED. Labels and packaging often require vibrant colors and durable finishes. LED curing provides instant drying. This allows for faster production speeds. It also means inks and coatings perform optimally. The consistent output means fewer make-ready sheets. Waste is reduced. This directly impacts profitability for short runs.

Label Printing: Consistency is non-negotiable for labels. Whether it’s food, cosmetic, or industrial labels, appearance matters. LED curing ensures that every label produced has the same level of cure. This means consistent gloss, matte finishes, and color vibrancy. It also guarantees good adhesion to various substrates. Short-run label printers can now offer high-quality, consistent products.

Sheetfed Offset Printing: While traditionally associated with longer runs, sheetfed offset is adapting. Short runs are now common. LED curing provides immediate curing for sheets. This allows for instant handling. It eliminates the need for long drying times or special coatings. Color consistency across short runs is maintained. This is a significant improvement.

UV Curing Knowledge and LED Technology

The science behind UV curing is fascinating. Traditional UV lamps generate heat. This can warp thin substrates. It can affect ink stability. LED systems produce very little heat. This is a huge advantage for heat-sensitive materials. Think about shrink sleeves or certain plastics used in packaging.

The specific wavelengths emitted by LED systems are also important. They can be tailored to different ink and coating formulations. This allows for optimal curing efficiency. It ensures that the entire ink layer is cured. Not just the surface. This leads to superior scratch and chemical resistance.

Cost-Effectiveness and Environmental Impact

Beyond consistency, LED curing offers other benefits. Energy consumption is lower. LED lamps use significantly less power than mercury lamps. They also have a much longer lifespan. This reduces maintenance costs. There are no bulbs to replace frequently.

From an environmental standpoint, LED is greener. Mercury lamps contain hazardous materials. LED lamps do not. Their lower energy usage also contributes to a smaller carbon footprint. For printers focused on sustainability, LED is a clear choice.

For short-run printing, the ability to switch jobs quickly is vital. LED curing’s instant on/off nature means no waiting. This minimizes downtime between jobs. It maximizes press utilization. This is a direct economic benefit.

Conclusion

The shift to LED curing systems is clear. For printers handling short-run jobs, it’s a smart investment. The consistent results are undeniable. This impacts everything from print quality to production efficiency. Whether you’re in narrow web flexo, label printing, or sheetfed offset, LED offers a reliable path. It ensures that every print meets expectations. The technology is mature. It delivers on its promise of superior, consistent output for today’s dynamic print market.