How LED Curing Systems Enable Sustainable Label Manufacturing

The packaging industry, particularly label manufacturing, is undergoing a transformative shift toward more sustainable practices. With the increasing demand for eco-friendly solutions, manufacturers are turning to innovative technologies like LED UV curing to optimize their processes. This shift not only benefits the environment but also enhances efficiency and productivity in printing. In this article, we will explore how LED curing systems are revolutionizing sustainable label manufacturing, particularly in flexographic printing, narrow-web printing, and UV curing applications.

What is LED UV Curing?

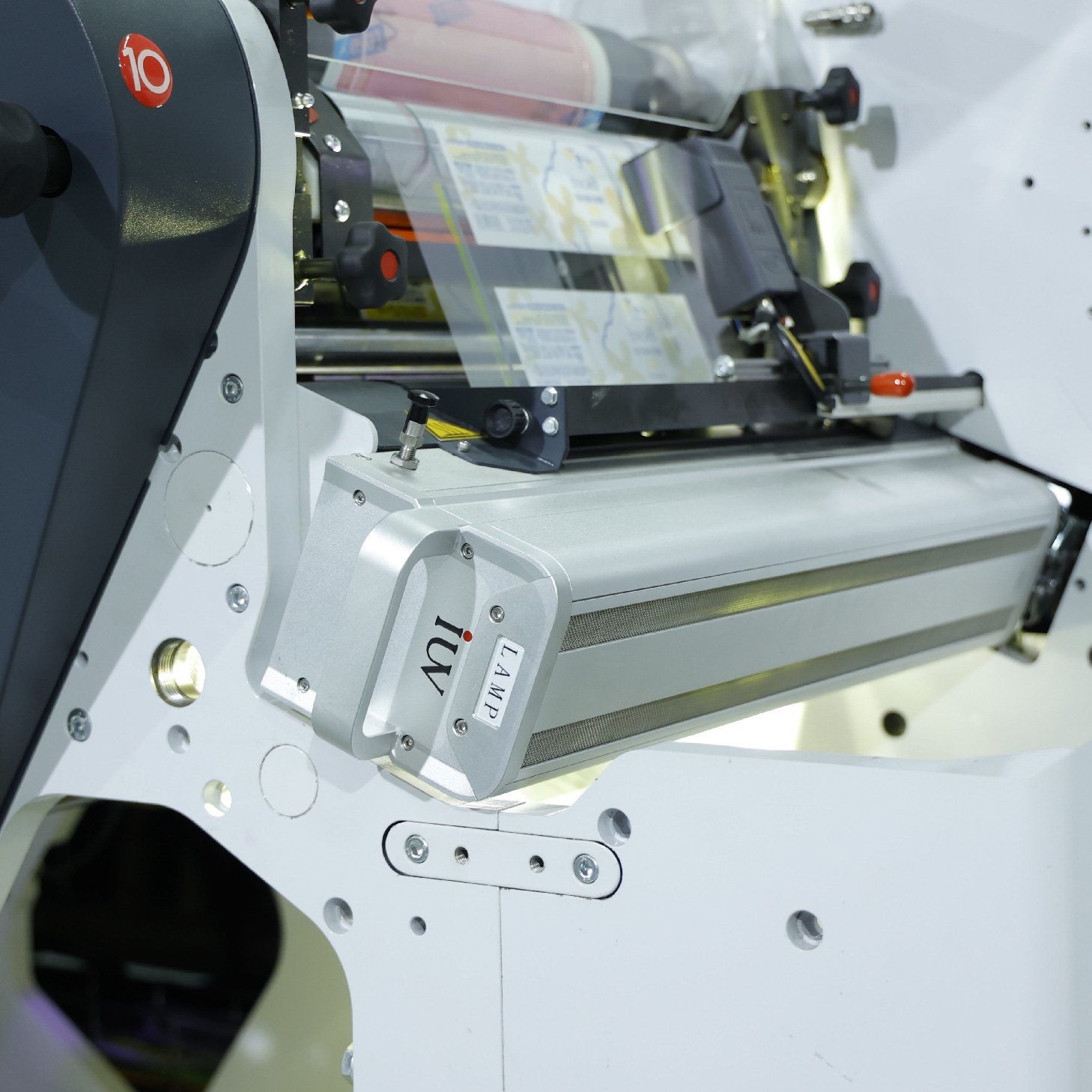

LED UV curing is a process in which ultraviolet light is used to rapidly cure or dry inks, coatings, and adhesives in a fraction of the time traditional methods take. Unlike conventional mercury-based UV lamps, LED curing systems use light-emitting diodes (LEDs) to deliver UV energy, providing several advantages such as energy savings, longer lamp life, and a cleaner, more environmentally friendly process.

The use of LED UV curing systems in label printing enables a more sustainable approach. These systems consume less energy and produce lower levels of heat, reducing the overall energy consumption of the printing process. Additionally, LED lamps emit minimal ozone and UV emissions compared to traditional mercury vapor lamps, making them safer for operators and more environmentally friendly.

The Role of LED Curing in Flexographic Printing

Flexographic printing has long been the dominant method for producing high-quality labels, especially for packaging. The flexibility of flexographic presses allows printers to work with a variety of substrates, including paper, films, and other materials. Traditionally, this method relied on solvent-based inks that required longer drying times and contributed to higher emissions and waste.

LED UV curing technology has had a significant impact on flexographic printing. By curing inks instantly, LED UV systems reduce drying times from minutes to seconds, which helps in increasing print speeds and production efficiency. The ability to dry ink instantly also reduces the need for energy-intensive drying tunnels, cutting down the energy usage and reducing the environmental impact.

Furthermore, LED UV curing enables the use of low-VOC (volatile organic compounds) inks that are more sustainable than traditional solvent-based options. These inks release fewer harmful chemicals into the environment, contributing to a healthier workplace and reducing the overall environmental footprint of the label manufacturing process.

Benefits of LED Curing in Narrow-Web Printing

Narrow-web printing is particularly prevalent in the production of labels for consumer goods, cosmetics, and food packaging. This type of printing is characterized by its ability to print on smaller, thinner substrates, and it is often used for high-quality, detailed designs that require precise color reproduction.

The adoption of LED UV curing in narrow-web printing offers several key advantages. One of the most notable benefits is the ability to print on a wider variety of materials. LED UV systems cure inks on both non-porous and porous substrates, including films and coated papers, without compromising the quality of the print. This versatility allows manufacturers to produce labels with high color fidelity and superior finish, all while using fewer resources.

Moreover, the fast curing times offered by LED technology increase production speed and throughput. This leads to higher efficiency on the production floor and a reduction in material waste, as less time is spent waiting for inks to dry. Additionally, LED curing systems have a longer lifespan than traditional mercury-based UV lamps, resulting in reduced replacement costs and lower waste over time.

Environmental Impact of LED UV Curing in Label Printing

The move towards LED UV curing technology is a major step forward in reducing the environmental impact of label manufacturing. Traditional UV curing systems use mercury vapor lamps, which require more energy and have a shorter lifespan. These lamps also emit ozone, which contributes to air pollution. By contrast, LED UV curing lamps are more energy-efficient and do not emit ozone, making them a cleaner and safer option for the environment.

LED UV curing systems also produce significantly less heat, which reduces the need for cooling systems on presses. This reduction in heat lowers energy consumption, helping manufacturers cut down on electricity costs and their carbon footprint.

Additionally, LED UV curing supports the use of more sustainable materials. Many LED-curable inks are designed to be more eco-friendly, using renewable resources and reducing harmful chemicals in the production process. This is particularly important in an era when sustainability is becoming a priority for both consumers and regulators.

Cost Efficiency and Productivity Gains with LED Curing

While the initial investment in LED curing systems may be higher than traditional UV curing equipment, the long-term cost savings and productivity gains make it a smart investment. LED UV systems are highly energy-efficient, consuming up to 80% less energy than conventional mercury vapor lamps. The reduced energy consumption translates to lower electricity bills and a more cost-effective production process.

In addition, LED lamps last much longer than mercury lamps, with a lifespan of up to 20,000 hours compared to only 1,000 hours for traditional lamps. This extended lifespan reduces maintenance costs and the need for frequent replacements, making LED UV curing systems a more economical choice in the long run.

The fast curing times provided by LED UV technology also lead to higher production speeds, enabling manufacturers to complete more jobs in less time. This increased throughput results in a significant boost in productivity, allowing businesses to take on more projects and improve their bottom line.

The Future of Sustainable Label Manufacturing

As the demand for sustainable practices continues to rise, LED UV curing systems will play an increasingly important role in the label manufacturing industry. Manufacturers are continuously exploring new ways to reduce their environmental impact while maintaining high-quality production standards. LED UV curing offers a proven solution to these challenges, providing a more sustainable, efficient, and cost-effective method of label printing.

In the future, we can expect to see even more innovations in LED curing technology, including improvements in ink formulations and further reductions in energy consumption. As these technologies continue to evolve, they will further support the industry’s shift towards sustainability, offering even greater benefits for both manufacturers and the environment.

Conclusion

LED UV curing systems are transforming the label manufacturing industry, enabling more sustainable, efficient, and high-quality production processes. With benefits such as faster curing times, reduced energy consumption, and the ability to use eco-friendly inks, LED curing is helping manufacturers meet the growing demand for environmentally responsible packaging solutions. As the technology continues to advance, the role of LED curing in sustainable label manufacturing will only become more significant, shaping the future of the industry for years to come.