LED Curing Systems are dramatically changing flexographic printing. This technology offers significant advantages. It enhances speed and efficiency in label and narrow web printing. Many printers are looking for ways to improve their operations. Adopting LED UV curing is a smart move.

Flexographic printing, often called flexo, is a versatile printing method. It uses a flexible relief plate. This plate transfers ink onto a substrate. Flexo is ideal for printing on a wide range of materials. This includes plastic films, paper, and cardboard. It is especially popular in the packaging and label industries. Narrow web printing focuses on smaller format printing. Think of the labels on your food products. These are often produced on narrow web flexo presses.

Traditionally, flexo presses used mercury vapor lamps for UV curing. These lamps emit a broad spectrum of UV light. They also produce a lot of heat. This heat can be a problem. It can cause some substrates to warp or degrade. High heat also means higher energy consumption. These older systems require significant warm-up times. They also need regular maintenance and replacement of bulbs. The disposal of mercury bulbs also presents environmental concerns.

This is where LED UV curing systems come in. LED stands for Light Emitting Diode. These systems use solid-state semiconductor devices. They emit UV light at specific wavelengths. This precise control over wavelength is a major benefit. It allows for efficient curing of UV-curable inks and coatings. Unlike mercury lamps, LEDs emit very little heat. This makes them ideal for heat-sensitive substrates. Think of thin plastic films used for flexible packaging.

The energy efficiency of LED curing is remarkable. LEDs consume significantly less power than mercury lamps. They reach full intensity almost instantly. There is no need for a warm-up period. This saves time and energy. It also contributes to a lower carbon footprint. For businesses, this translates directly into lower operating costs. Reducing energy bills is a key objective for many print operations.

Optimizing flexographic printing processes with LED curing means faster production speeds. Because LEDs provide instant, high-intensity curing, presses can run much faster. This boosts throughput and allows printers to meet demanding deadlines. In the competitive label market, speed is often a critical factor. Faster turnaround times mean happier customers. It also means more jobs can be completed in the same amount of time.

The focused UV spectrum from LEDs also leads to better ink performance. UV-curable inks are formulated to react to specific wavelengths. LEDs deliver the precise wavelengths needed for optimal curing. This results in harder, more durable ink films. It also improves ink adhesion to various substrates. The print quality is often superior. Colors can be more vibrant. Gloss levels can be enhanced. This is important for eye-catching labels.

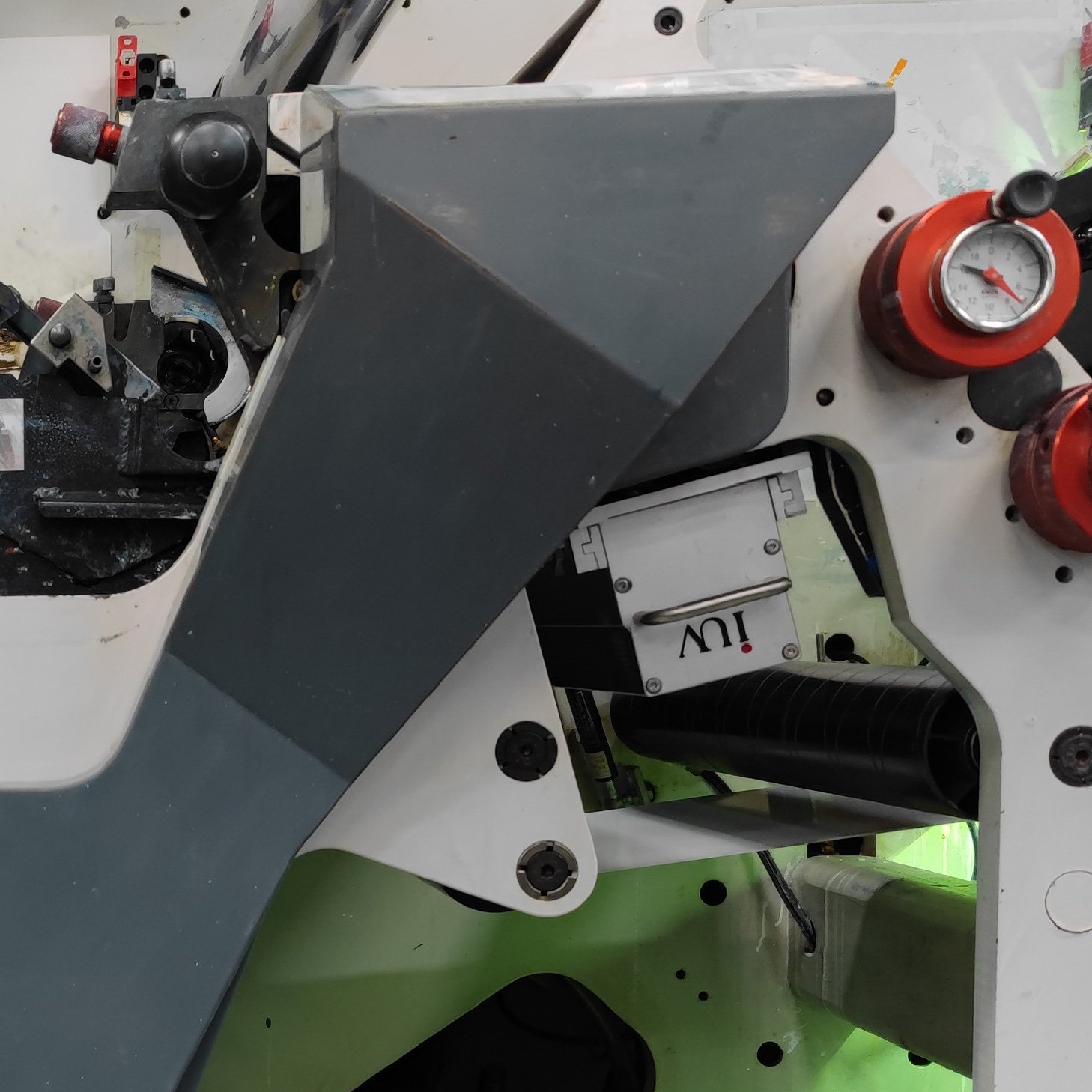

LED curing systems are also more compact than traditional UV systems. This allows for easier integration into existing flexographic presses. They can be retrofitted onto older machines. This provides a cost-effective upgrade path. It avoids the need for completely new press purchases. The lifespan of LED lamps is also significantly longer. They can last tens of thousands of hours. This reduces maintenance downtime and replacement costs.

In narrow web printing, space is often at a premium. The compact nature of LED systems is a huge advantage. They can be installed in tight spaces on the press. This allows for more flexible press configurations. It enables printers to adapt their equipment to different job requirements.

The environmental benefits are also substantial. As mentioned, LEDs use less energy. They also do not contain mercury. This makes them a much greener printing solution. Many brands are now demanding more sustainable packaging. Adopting LED curing helps printers meet these sustainability goals. It can be a significant selling point for their services.

Beyond labels, flexographic printing is used for many other applications. These include folding cartons, flexible packaging, and corrugated boxes. In all these areas, LED curing can offer improvements. The ability to cure thicker ink layers or specialized coatings efficiently is a major plus. This opens up new possibilities for print embellishments and finishes.

Consider the challenges in offset printing, also known as lithography. While different from flexo, offset printing also uses UV curing for some applications. The heat generated by traditional UV lamps can be an issue in offset too. LED UV curing can offer similar benefits in terms of speed, energy saving, and substrate compatibility for specific offset applications. However, flexographic printing has seen the most profound impact from LED technology due to its prevalence in the high-volume, fast-paced label and packaging sectors.

The integration of LED UV curing is not just a technological upgrade. It represents a strategic advantage for flexographic printers. It leads to higher productivity, improved print quality, and reduced operational costs. The environmental benefits also align with modern business values and customer demands.

For printers looking to stay competitive, understanding and implementing LED curing technology is key. It’s an investment in the future of their business. The shift from older UV technologies to LED is accelerating. Those who embrace this change will be well-positioned for success. The technology continues to evolve. New LED systems offer even greater power and flexibility. This ensures that LED curing will remain at the forefront of printing innovation.