The landscape of label printing is in constant flux. Brands require greater flexibility, faster turnaround times, and the ability to cater to diverse product lines. This shift has placed immense pressure on traditional printing methods. However, advancements in high-speed UV flexo printing are providing a powerful solution, especially for short-run and on-demand label production. This technology is not just an evolution; it’s a revolution in how labels are conceived, produced, and delivered.

The Growing Demand for Short-Run and On-Demand Labels

Several factors are driving the demand for shorter print runs and on-demand label capabilities. Firstly, the proliferation of SKUs means that many products require unique labeling. This is particularly true in consumer goods, where product variations, regionalizations, and promotional campaigns necessitate frequent label changes. Secondly, a growing awareness of waste reduction and inventory management encourages brands to print only what they need, when they need it. This “just-in-time” approach minimizes obsolescence and storage costs. Finally, the rise of e-commerce and direct-to-consumer models means that many businesses, especially smaller ones, can’t commit to large print runs. They need the agility to adapt their labeling quickly to changing market demands or new product introductions.

Why Traditional Methods Struggle

Traditional printing methods, such as offset and gravure, are optimized for very long print runs. Their setup times are significant, involving the creation of plates, precise ink adjustments, and extensive press calibration. While they offer excellent quality for large volumes, the cost per label for short runs becomes prohibitively high. Furthermore, the lengthy setup process means that any changes or corrections can cause significant delays. This inflexibility is a major drawback in today’s fast-paced market. Even some conventional flexographic presses, while more adaptable than offset or gravure, can still face challenges with the speed and efficiency required for true on-demand production.

The Power of UV Flexo Printing

Flexographic printing, or flexo, has long been a workhorse for label printing due to its versatility. It uses a raised flexible printing plate to transfer ink onto a substrate. This method is effective on a wide range of materials, including films, foils, and papers. When combined with UV (ultraviolet) curing technology, flexo printing enters a new realm of performance. UV curing involves using UV light to instantly dry or “cure” inks, coatings, and adhesives. This immediate drying process is critical for high-speed operations.

How High-Speed UV Flexo Addresses Challenges

High-speed UV flexo presses are engineered for maximum throughput and minimal downtime. They incorporate advanced automation, precise registration systems, and, crucially, high-intensity LED UV curing units. Here’s how they specifically support short-run and on-demand labels:

- Reduced Setup Times: While flexo still requires plates, the process is generally faster than offset or gravure. Modern flexo presses offer quick plate mounting systems and automated ink management. This significantly slashes the time needed to switch between jobs.

- Unmatched Speed: High-speed presses can operate at speeds of hundreds of feet per minute. The instant curing provided by UV inks means that the printed substrate can be immediately wound up or processed further without smearing or smudging. This sustained high speed is maintained from the first label to the last, regardless of run length.

- Versatility with Substrates: UV flexo inks adhere well to a wide array of substrates, including challenging materials like flexible films and textured papers. This allows printers to offer diverse labeling solutions without needing multiple press types.

- Consistent Quality: The precise control offered by modern flexo presses, combined with the consistent curing of UV lamps, ensures high-quality output for every label. Registration is maintained even at high speeds, leading to sharp graphics and crisp text.

- Cost-Effectiveness for Short Runs: Although the initial investment in UV flexo technology can be substantial, the operational efficiencies it provides make short runs significantly more economical. Reduced waste, faster job changeovers, and higher press utilization all contribute to a lower cost per label, even for runs as small as a few hundred or a few thousand labels.

- On-Demand Production: The combination of fast setup, high speed, and consistent quality makes true on-demand label printing a reality. Printers can receive orders for small batches of labels and produce them very quickly, fulfilling customer needs with unprecedented agility.

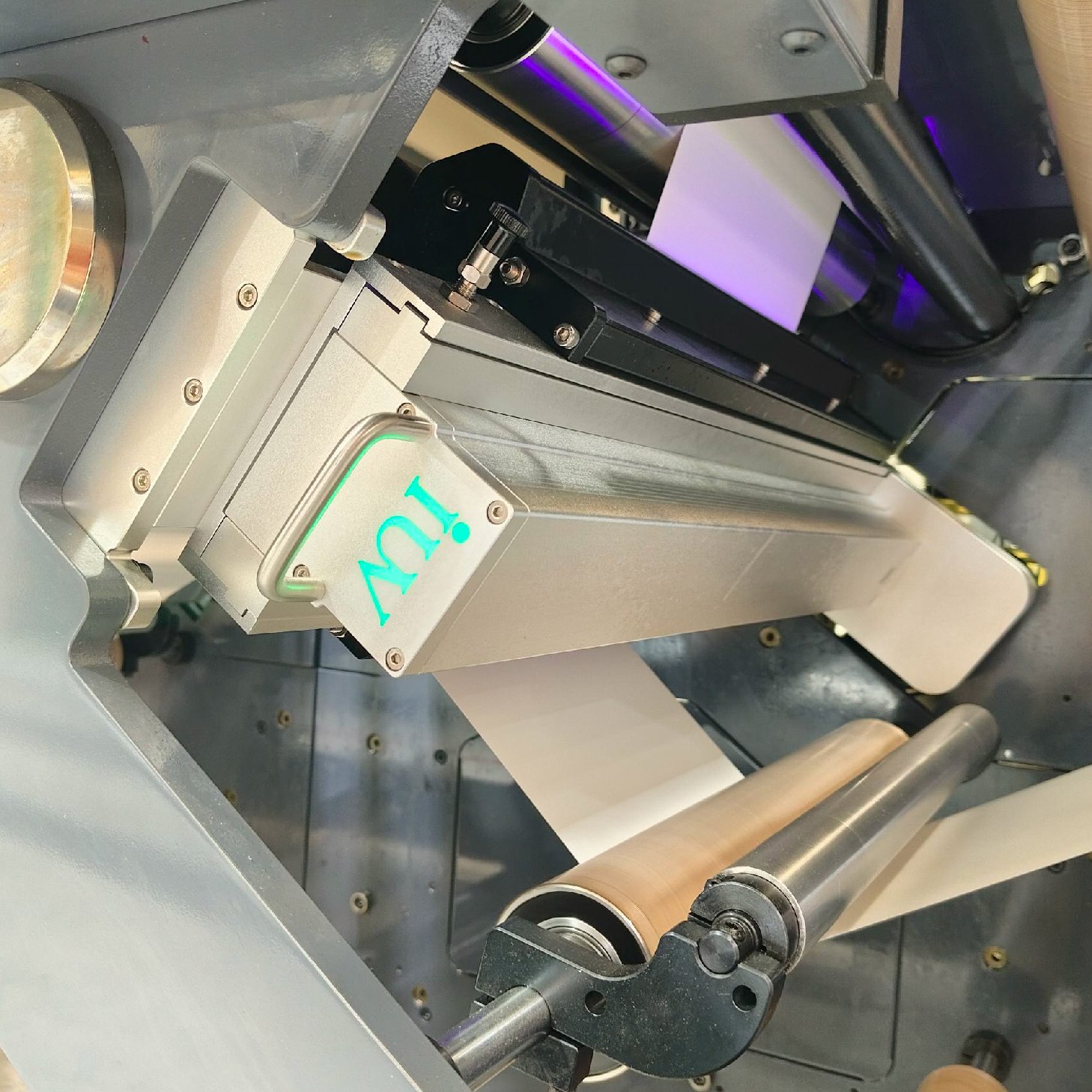

The Role of LED UV Curing

The advent of LED UV curing technology has been a significant leap forward for UV flexo printing. Unlike traditional mercury vapor UV lamps, LED lamps offer numerous advantages:

- Energy Efficiency: LEDs consume considerably less power, leading to reduced operating costs.

- Longer Lifespan: LED lamps have a much longer operational life, reducing maintenance and replacement expenses.

- Instant On/Off: LEDs turn on and off instantly, meaning there’s no warm-up time, which further speeds up job changeovers and reduces energy waste.

- Lower Heat Emission: LEDs generate less heat, which is beneficial for printing on heat-sensitive substrates and can improve operator comfort.

- Compact Design: LED units are more compact, allowing for easier integration into printing presses, especially for multiple curing stations between print units.

- Focused Wavelength: LEDs emit a specific wavelength of UV light that is highly efficient for curing UV inks and coatings, ensuring complete and rapid polymerization.

Ink Technology and Formulation

The inks used in UV flexo printing are specially formulated to react to UV light. These inks contain monomers, oligomers, photoinitiators, and pigments. When exposed to UV light, the photoinitiators absorb the energy and trigger a chain reaction, causing the monomers and oligomers to link together, forming a solid, cured ink film. For high-speed printing, ink formulations must be designed to cure rapidly and completely under intense UV exposure without causing issues like premature curing on the press or insufficient cure at high speeds. Advances in UV ink chemistry have led to formulations that offer excellent adhesion, durability, color brilliance, and resistance to chemicals and abrasion, all while curing instantaneously at high speeds.

Applications and Market Impact

High-speed UV flexo printing is transforming various sectors that rely heavily on custom labeling:

- Food and Beverage: Allows for dynamic labeling for seasonal products, promotional offers, or regional variants, all produced quickly to meet market demand.

- Health and Beauty: Supports the launch of new product lines or limited editions, where speed to market is crucial.

- Pharmaceuticals: Enables the printing of small batches of labels for clinical trials, specialized medications, or products with short shelf lives.

- Industrial Products: Facilitates the production of custom labels for various equipment, components, or spare parts on demand.

- Craft Breweries and Wineries: Provides flexibility for smaller producers to create eye-catching labels for different batches or special releases without incurring massive setup costs.

The Future Outlook

The trend towards personalization, customization, and agility in product packaging will only intensify. High-speed UV flexo printing, with its inherent advantages in speed, flexibility, and quality, is perfectly positioned to meet these evolving demands. As technology continues to advance, we can expect even faster press speeds, more sophisticated automation, and further improvements in UV curing efficiency and ink formulations. This will further solidify its role as the premier solution for short-run and on-demand label production, offering brands the ability to respond instantly to market opportunities and consumer preferences. The integration of digital workflows with high-speed UV flexo presses will also streamline the entire production process, from order placement to final delivery, making label customization and rapid deployment more accessible than ever before.