Printing high-quality labels for food packaging demands precision. It also requires adherence to strict regulations. Especially when it comes to food safety. The ink must not migrate into the food product. This is a critical concern for brand owners and consumers alike. Traditional curing methods have limitations. They often struggle to meet these low-migration requirements. They can also be energy-intensive. This is where advanced curing technologies come into play. High-intensity LED curing systems are changing the game. They offer a powerful solution for low-migration food packaging labels.

The Challenge of Low-Migration in Food Packaging

Low migration means that substances from the ink or coating do not transfer to the food. This transfer can happen through direct contact or vapor. It’s a significant safety issue. Regulatory bodies worldwide set strict limits. These limits govern the levels of substances allowed. Especially in materials that come into contact with food. For printers, this means selecting the right inks. It also means choosing the right curing technology. The curing process must fully polymerize the ink. This ensures it is inert and stable. Any uncured components pose a migration risk.

Traditional Curing Limitations

For years, mercury vapor lamps were the standard. These lamps emit UV light. They are effective at curing inks. However, they have drawbacks. They generate substantial heat. This heat can damage sensitive substrates. It can also affect the ink itself. Mercury vapor lamps have a limited lifespan. They require frequent replacement. They also consume a lot of energy. Furthermore, achieving complete cure can be challenging. This can leave residual unreacted monomers. These are a primary source of migration.

The Rise of LED UV Curing Technology

Light Emitting Diodes (LEDs) offer a different approach. LED curing systems use solid-state technology. They emit UV light at specific wavelengths. This is a key advantage. The wavelengths can be precisely controlled. This ensures optimal energy absorption by the ink’s photoinitiators. High-intensity LEDs can deliver a powerful UV dose. This leads to very fast and complete curing. The energy efficiency of LEDs is remarkable. They consume significantly less power than mercury lamps. They also produce very little heat. This is beneficial for a wide range of substrates.

Benefits of High-Intensity LED for Food Labels

For food packaging labels, the benefits are substantial.

- Enhanced Low-Migration Performance: High-intensity LED curing systems achieve a very thorough cure. This significantly reduces the presence of uncured components. This directly translates to lower migration potential. This is paramount for compliance with food contact regulations. Many specialized low-migration inks are formulated for LED curing. They react efficiently under LED wavelengths.

- Substrate Versatility: The low heat output of LEDs is a major plus. This allows for the printing on a wider array of materials. This includes thin films and heat-sensitive plastics. These are common in food packaging. This expands the design possibilities for brands. It also simplifies production for printers.

- Energy Efficiency and Cost Savings: LEDs are incredibly energy-efficient. They use up to 70% less energy than traditional UV lamps. They also have a much longer operational life. This means lower electricity bills and reduced maintenance costs. The lamps don’t need frequent replacement. This minimizes downtime.

- Instant On/Off Capability: LEDs can be switched on and off instantly. This is unlike mercury lamps that require warm-up and cool-down periods. This capability saves energy. It also reduces wear and tear. It allows for more precise control during the printing process.

- Environmental Advantages: With no mercury content, LEDs are more environmentally friendly. Their energy efficiency also contributes to a reduced carbon footprint. This aligns with growing sustainability demands in the food industry.

Application in Different Printing Processes

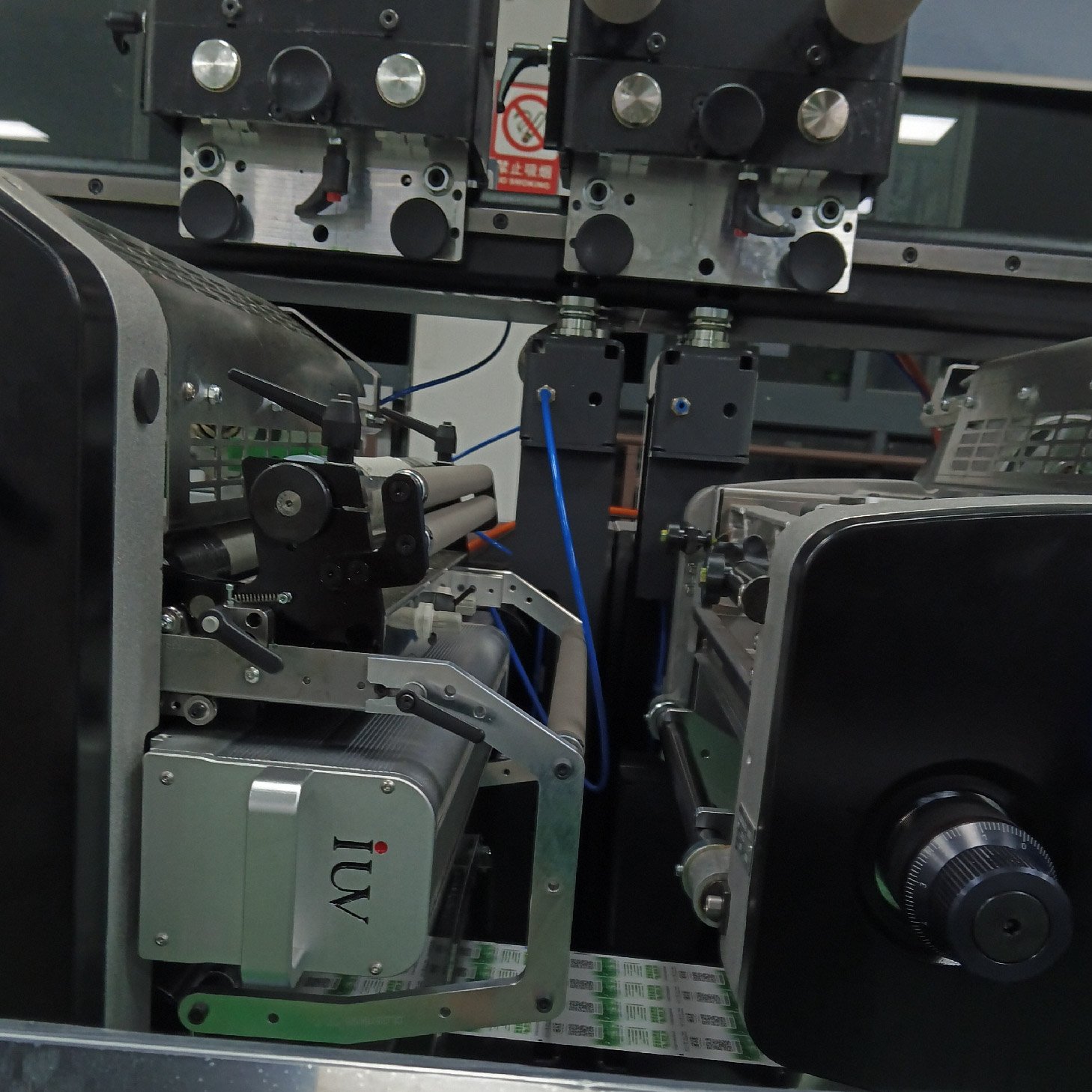

High-intensity LED curing systems are adaptable. They integrate seamlessly into various printing technologies used for narrow web labels.

- Flexographic Printing: Flexo is a dominant printing method for labels. LED curing units can be retrofitted onto existing flexo presses. Or specified on new equipment. They provide the necessary UV energy for curing inks and coatings. This is crucial for achieving the required low-migration properties. Specialized LED-curable inks are available for flexo. They are designed for high-speed production.

- Offset (Lithographic) Printing: For high-volume label runs, offset printing is often used. Narrow web offset presses can also be equipped with LED UV curing. This allows for immediate drying of inks. This is essential for multi-color prints. It prevents ink smudging. The low heat is also advantageous for sensitive paper stocks.

- Screen Printing: While less common for mainstream food labels, screen printing is used for special effects or durable labels. LED curing works effectively with screen printing inks. It ensures a durable, well-cured layer. This is important for labels exposed to harsh conditions.

Selecting the Right LED System

Choosing the correct LED curing system involves several considerations.

- Wavelength: The wavelength of the LEDs must match the photoinitiators in the ink. Common wavelengths for LED curing are 365 nm, 385 nm, 395 nm, and 405 nm. Ensure compatibility with your chosen ink system.

- Irradiance (Intensity): This is the power density of the UV light. Higher irradiance leads to faster and more thorough curing. It’s measured in W/cm². The required irradiance depends on press speed and ink formulation. High-intensity systems offer superior irradiance levels.

- Dose: This is the total amount of UV energy delivered to the ink. It’s calculated as irradiance multiplied by exposure time. A sufficient UV dose is critical for full polymerization.

- Cooling: Even though LEDs produce less heat, effective cooling is still important. This ensures consistent performance and longevity of the LED modules.

- Integration: The system must be compatible with your printing press. This includes physical dimensions and electrical requirements.

Formulating for LED Curing and Low Migration

Ink manufacturers play a vital role. They develop specialized inks and coatings. These are formulated specifically for LED curing. These formulations utilize photoinitiators. These initiators are highly reactive to specific LED wavelengths. They are also designed to minimize the presence of volatile organic compounds (VOCs). And low-molecular-weight oligomers. These are common culprits in migration issues. Working with ink suppliers who understand LED technology is key. They can guide you toward the best low-migration solutions.

The Future of Food Packaging Label Printing

High-intensity LED curing systems are not just a trend. They represent a significant technological advancement. They address critical needs in the food packaging label market. The demand for safe, compliant, and high-quality labels continues to grow. LED technology enables printers to meet these demands efficiently. It offers improved performance, lower operational costs, and environmental benefits. For businesses involved in narrow web printing of food packaging labels, investing in high-intensity LED curing is a strategic move. It ensures future readiness. It supports compliance. It delivers superior print quality.