The printing industry is constantly evolving. Innovation drives better quality and efficiency. Sustainability is also a major focus for many businesses. UV curing technology plays a vital role in these advancements. Specifically, LED UV curing systems are leading the way. They offer significant advantages over traditional methods. This technology is transforming various printing sectors, from labels to packaging.

For label printing, UV curing is already a standard. However, LED UV systems take it to a new level. They provide instant drying of inks and coatings. This allows for faster production speeds. Labels can be finished immediately after printing. This reduces turnaround times dramatically. The precision of LED UV light ensures sharp details. It also enhances color vibrancy on a wide range of substrates. From paper to plastics, LED UV performs exceptionally well. This adaptability is key for the diverse demands of label manufacturers.

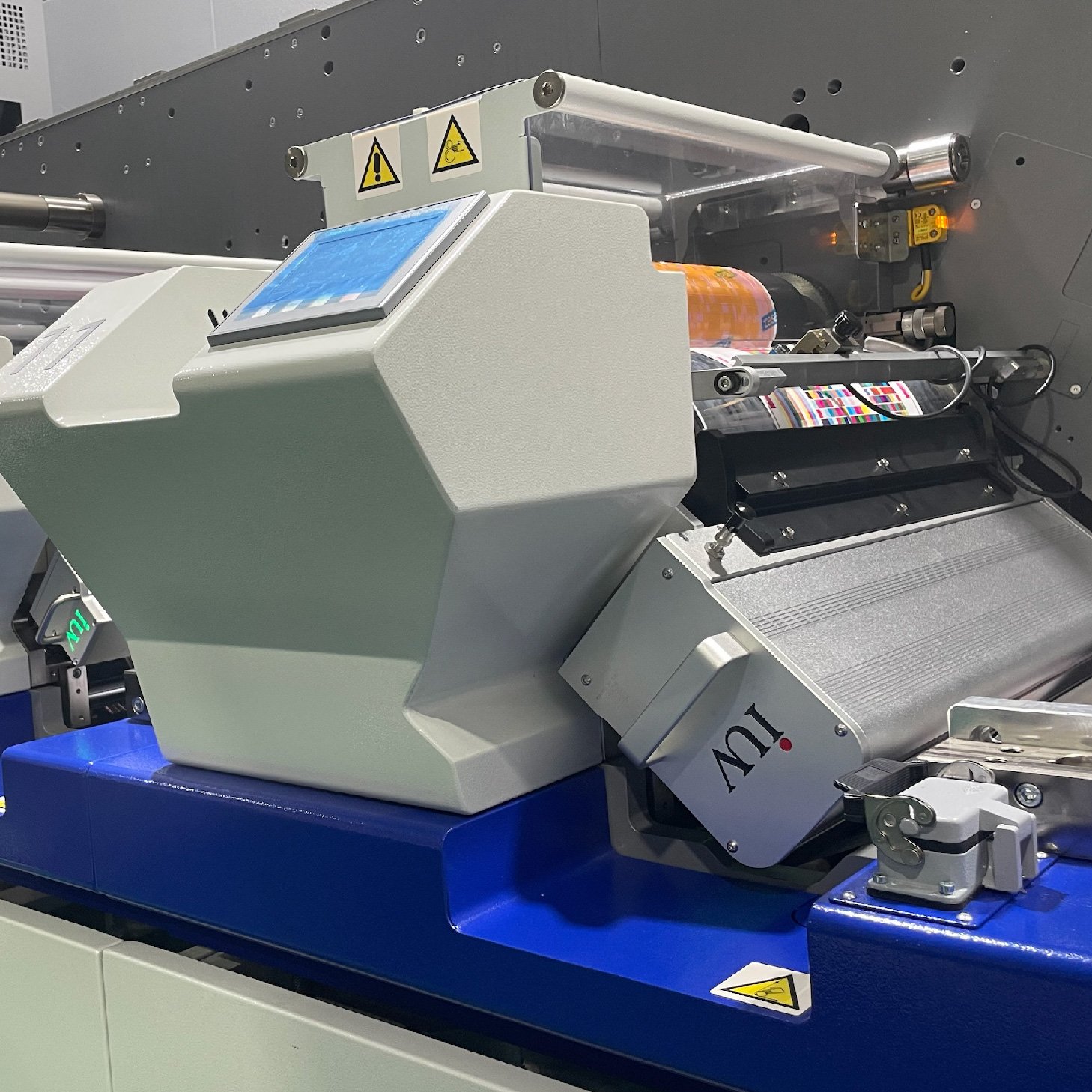

The flexibility of LED UV systems is another strong point. They can be integrated into existing narrow web presses. This makes upgrading more accessible. Manufacturers don’t need to replace their entire machinery. The energy efficiency of LEDs is remarkable. They consume less power compared to conventional UV lamps. This translates into lower operating costs. It also contributes to a smaller carbon footprint. This aligns perfectly with growing environmental concerns. Sustainable printing practices are no longer optional. They are a business imperative.

In flexographic printing, LED UV curing is making a significant impact. Flexo printing is widely used for packaging and labels. It requires fast drying inks to maintain print quality. Traditional UV lamps can generate considerable heat. This can affect the substrate, especially thin films. LED UV systems emit much less heat. This gentle curing process is ideal for sensitive materials. It prevents warping or distortion. This means consistent high-quality prints every time.

The instant curing nature of LED UV also benefits flexo printing. It prevents ink from spreading or smudging. This is crucial for achieving sharp lines and fine text. The durability of UV-cured inks is another advantage. They offer excellent resistance to abrasion and chemicals. This is vital for products that undergo harsh handling or exposure. Think about food packaging or industrial labels. They need to withstand demanding conditions. LED UV inks provide that robust protection.

Offset printing, also known as lithographic printing, is another area seeing rapid adoption. For sheetfed and web offset presses, LED UV offers enhanced capabilities. It allows for immediate stacking of printed sheets. This eliminates drying delays. It also reduces the risk of offsetting, where wet ink transfers to the next sheet. This improves workflow efficiency significantly. The ability to print on non-porous substrates is also a game-changer. Traditionally, offset inks required absorbent paper. LED UV inks can cure on plastics, foils, and coated papers. This opens up new creative possibilities for designers and printers.

The spectral output of LED UV lamps can be precisely controlled. This allows for optimized curing of different ink formulations. Ink manufacturers are developing specialized UV inks for LEDs. These inks cure faster and more efficiently. They often have lower VOC content. This further enhances the sustainability profile. The long lifespan of LED lamps is also a considerable benefit. They last much longer than mercury vapor lamps. This reduces maintenance downtime and replacement costs.

Narrow web printing is a specialized sector. It focuses on producing small-format printed items. Labels, stickers, and flexible packaging are common applications. LED UV curing systems are a natural fit for narrow web presses. Their compact size and low heat output are ideal. They integrate seamlessly into these smaller machines. The speed required for narrow web printing is high. LED UV’s instant curing capability matches this pace perfectly. It ensures that prints are dry and ready for finishing processes without delay.

The environmental benefits of LED UV curing are substantial. Reduced energy consumption is a primary driver. Less electricity usage means lower greenhouse gas emissions. Many LED UV systems are also mercury-free. This eliminates the need for hazardous waste disposal associated with traditional lamps. This contributes to a safer working environment and a more responsible manufacturing process. The durability and longevity of LED lamps also reduce waste from frequent replacements.

Looking ahead, we can expect further advancements. Research is ongoing into even more energy-efficient LED designs. New ink formulations will continue to emerge. These will offer enhanced performance and sustainability. The integration of LED UV curing with digital printing technologies is also growing. This allows for short runs and variable data printing with high quality and fast turnaround. The trend is towards smarter, more adaptable, and environmentally friendly printing solutions.

The adoption of LED UV curing is not just about keeping up with technology. It’s about embracing a more sustainable and efficient future for print. It empowers printers to deliver higher quality products. It helps them meet the evolving demands of their customers. The shift towards LED UV is a clear indicator of where the industry is heading. It’s a path paved with innovation, efficiency, and environmental consciousness. The future of printing is undoubtedly bright, and LED UV systems are illuminating the way.