Illuminating the Future: LED Curing Systems and Sustainable Printing

The printing industry is evolving. Sustainability is no longer just a buzzword; it’s a core business driver. For printing operations, especially those focused on labels, flexible packaging, and commercial print, adopting eco-friendly technologies is paramount. One of the most significant advancements is the rise of LED UV curing systems. These systems offer a powerful alternative to traditional methods. They are reshaping how we think about efficiency, quality, and environmental impact.

The Shift from Traditional Curing to LED Technology

For decades, mercury vapor lamps dominated UV curing. While effective, they came with considerable drawbacks. Mercury lamps consume a lot of energy. They generate substantial heat, which can be detrimental to delicate substrates. Their lifespan is also limited, requiring frequent replacement. Furthermore, mercury itself is an environmental concern.

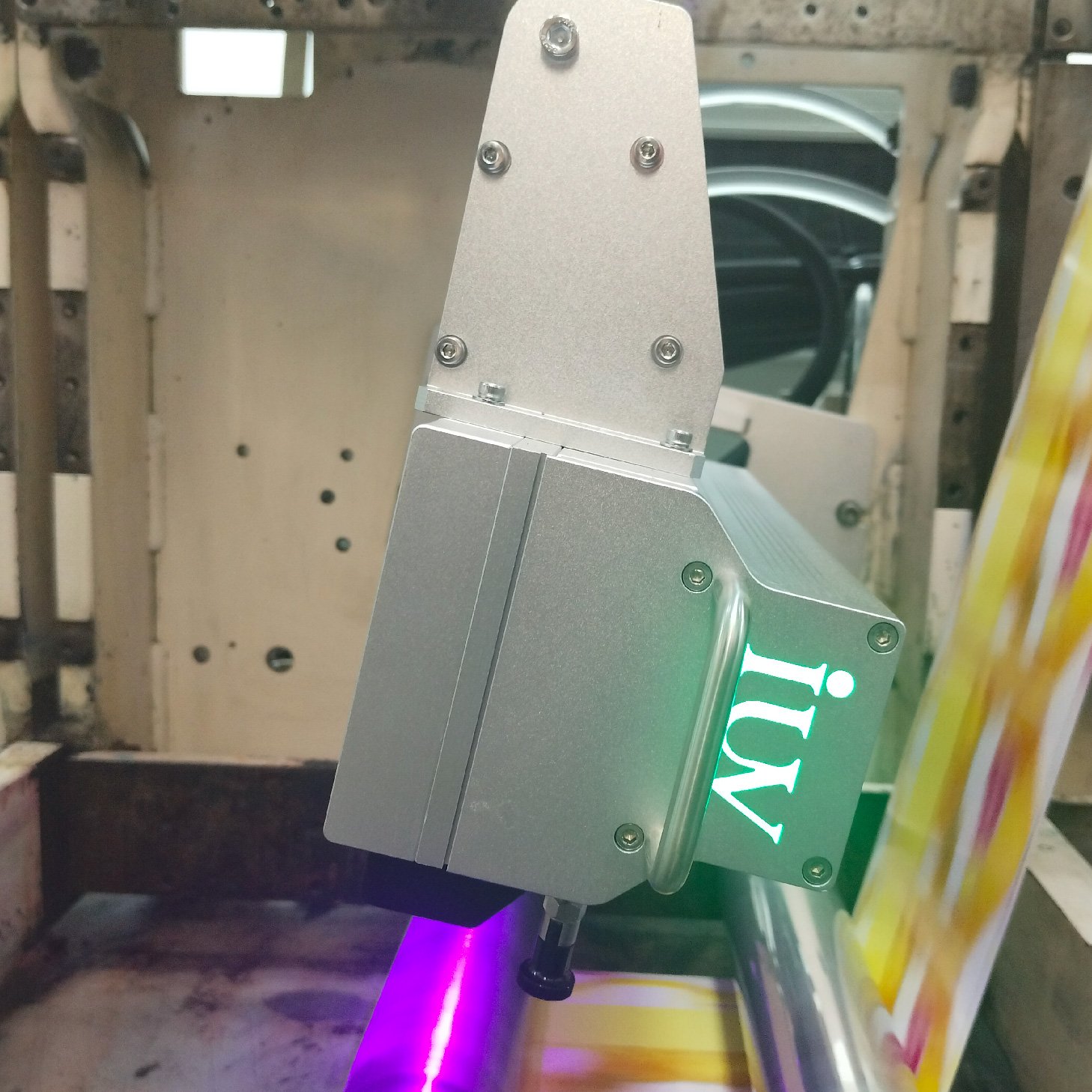

LED curing technology offers a compelling solution. Light Emitting Diodes (LEDs) produce UV light at specific wavelengths. This targeted emission means less wasted energy. It translates into significantly lower power consumption. The heat output is also much more controlled. This allows for printing on a wider range of materials, including heat-sensitive plastics and thin films. The operational lifespan of LED systems is also dramatically longer, often exceeding 20,000 hours. This reduces maintenance downtime and replacement costs.

LED Curing in Narrow Web and Label Printing

The narrow web printing sector, heavily reliant on label production, has been an early adopter of LED curing. The demand for high-quality, durable labels is immense. Brands require vibrant colors and sharp details. LED systems excel here. They provide instant curing, allowing for faster press speeds. This boosts productivity without compromising print quality.

In label printing, substrates can vary greatly. From papers to various plastic films, the ability to cure effectively without damaging the material is crucial. LED curing’s precise wavelength control and lower heat output make it ideal for these diverse applications. It enables printers to achieve excellent adhesion and scratch resistance on everything from premium wine labels to durable industrial stickers. The consistent curing performance ensures that each label meets stringent quality standards. This reliability is a significant advantage for label converters.

Flexographic Printing and the LED Advantage

Flexographic printing is a cornerstone of the packaging industry. It’s widely used for flexible packaging, cartons, and, of course, labels. Integrating LED UV curing into flexo presses brings substantial benefits. The speed of flexo presses demands rapid curing. LED technology meets this need, ensuring inks and coatings cure almost instantaneously.

This rapid curing is especially important for high-volume production runs. It prevents ink smudging and allows for immediate post-press handling. For food packaging, where regulatory compliance and safety are critical, the absence of mercury is a major plus. Furthermore, the energy savings realized with LED curing contribute to a more sustainable flexographic printing process. This aligns perfectly with the increasing demand for eco-conscious packaging solutions. The ability to print on a wider array of packaging materials also expands the creative possibilities for designers and brand owners.

Offset Printing Embraces LED Curing

Sheetfed and web offset printing are also benefiting from LED UV technology. Historically, offset printing relied on heatset or conventional UV lamps for drying and curing. LED curing offers a cleaner, more energy-efficient alternative. It allows offset printers to achieve instant drying on a variety of paper stocks. This eliminates the need for bulky drying units and reduces energy waste.

The reduced heat also means less ink set-off. This is a common problem in offset printing that requires special anti-set-off powders. With LED curing, these powders are often unnecessary. This leads to cleaner prints and a healthier working environment by reducing airborne particulates. For commercial printers, this translates to faster turnaround times and the ability to offer a wider range of finishing options. The consistent curing quality ensures sharp text and vibrant images, essential for high-quality brochures, magazines, and marketing collateral.

Sustainability Beyond Energy Savings

The environmental benefits of LED curing extend beyond reduced energy consumption. The elimination of mercury is a significant step towards a greener printing industry. Less heat generated by LEDs also means less strain on a facility’s HVAC systems, further contributing to energy efficiency.

Furthermore, the faster curing speeds enabled by LED technology can lead to increased throughput. This means more jobs can be completed in the same amount of time, optimizing resource utilization. The longer lifespan of LED lamps also means less waste from discarded bulbs. The overall reduction in operational waste, from energy to consumables, positions printers using LED curing as leaders in sustainable manufacturing.

The Future is Bright and Efficient

The trend towards LED UV curing systems in printing is undeniable. As the technology continues to mature, we can expect even greater advancements. Increased efficiency, broader wavelength options, and improved integration with existing press technologies are on the horizon. For printers focused on labels, flexo, offset, and narrow web applications, embracing LED curing is not just about staying current; it’s about investing in a more sustainable, efficient, and profitable future. The path to greener printing is illuminated by the consistent, powerful glow of LED technology.