In the dynamic landscape of modern printing, especially within label, flexographic, and offset (sheetfed) applications, the quest for efficiency and durability is paramount. Narrow web printing operations, in particular, demand solutions that enhance productivity without compromising equipment integrity. A significant advancement addressing these needs is the adoption of low-heat LED UV curing technology. This innovative approach offers a compelling alternative to traditional heat-set drying and conventional UV systems, directly contributing to an extended press lifespan.

The Challenge of Heat in Printing Processes

Traditional drying methods often rely on substantial heat. Heat-set drying, commonly used in offset and some web applications, requires ovens that can reach high temperatures to evaporate solvents. While effective, this prolonged exposure to heat places considerable stress on various press components. Substrates, inks, and even the press machinery itself endure thermal degradation over time. This can lead to premature wear on rollers, blankets, and other delicate parts, necessitating more frequent maintenance and replacements.

Conventional UV curing systems, while faster than heat-set, also generate a considerable amount of heat. Mercury vapor lamps, once the industry standard, emit a broad spectrum of UV light along with significant infrared radiation. This heat output can limit the types of substrates that can be used, especially heat-sensitive materials like thin films or certain paper stocks. Furthermore, the intense heat can contribute to thermal expansion and contraction of machine parts, potentially affecting print registration and overall mechanical accuracy.

Understanding LED UV Curing Technology

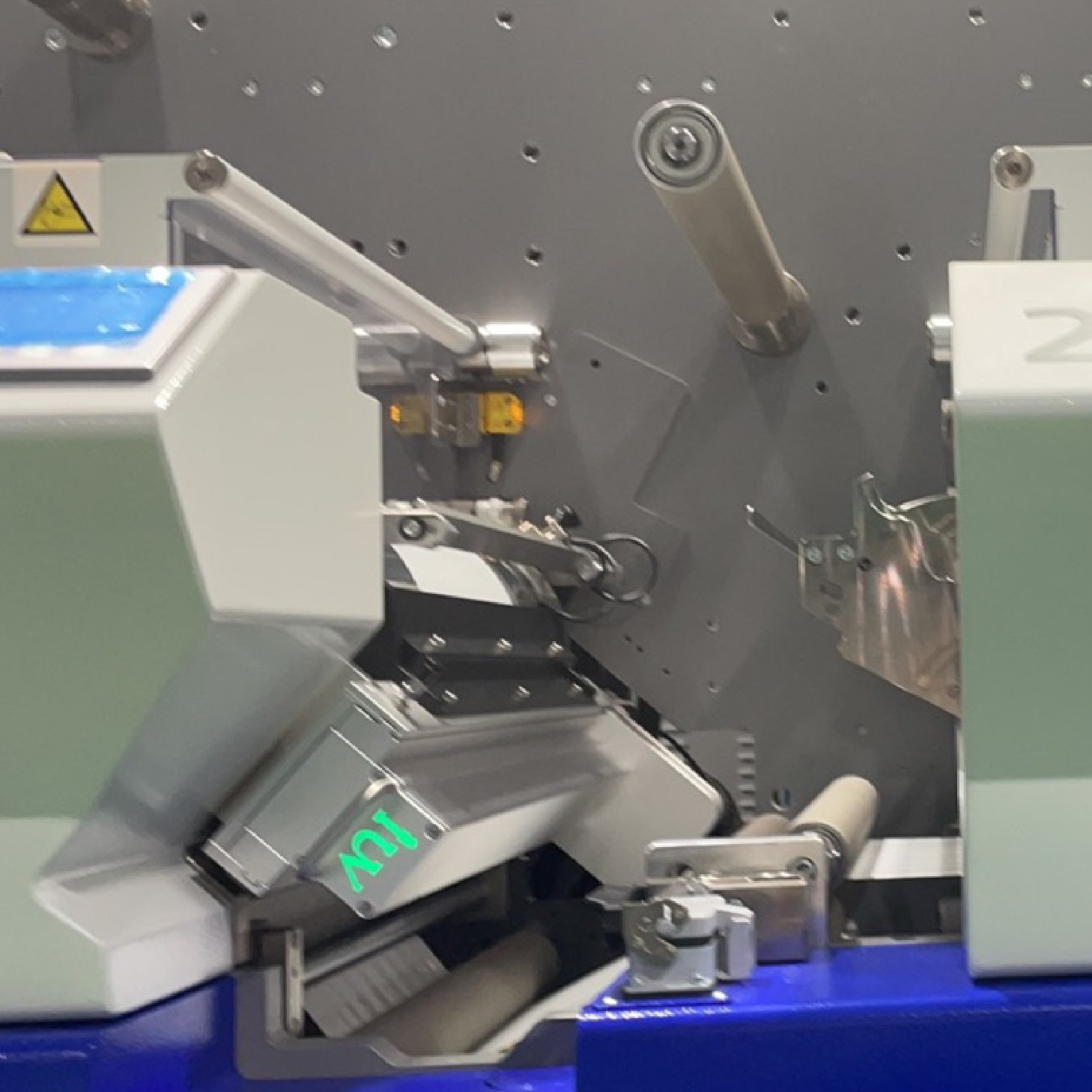

Light Emitting Diode (LED) UV curing represents a paradigm shift. Instead of relying on broad-spectrum mercury lamps, LED systems utilize specialized diodes that emit UV light at specific wavelengths. Crucially, LED UV lamps produce very little heat. Their energy output is highly focused on the UV spectrum required for ink polymerization, meaning less energy is wasted as infrared radiation. This inherent low-heat characteristic is the cornerstone of its benefit in extending press life.

The energy efficiency of LED UV curing is another key advantage. LED systems consume significantly less power compared to their mercury lamp predecessors. This translates to lower operational costs and a reduced environmental footprint. However, the primary focus here is on the quality of the energy delivered and its impact on the printing press.

Benefits for Narrow Web and Label Printing

For narrow web and label printers, substrates are often thin and can be susceptible to heat damage. Traditional drying methods can cause shrinkage, warping, or blistering on these delicate materials. Low-heat LED UV curing allows printers to maintain substrate integrity, preserving the quality of the final product. This opens up possibilities for using a wider range of materials, including sensitive plastics and foils, without the risk of heat-induced distortion.

In flexographic printing, where precise ink transfer and substrate handling are critical, the absence of excessive heat is a major boon. It helps maintain the dimensional stability of the printing plates and anilox rollers, ensuring consistent dot gain and sharp image reproduction. Reduced thermal stress on the web path minimizes the chances of registration issues, a common concern in high-speed narrow web operations.

Impact on Flexographic and Offset Presses

Flexographic presses benefit immensely from the low heat output. The reduced thermal load on rubber rollers, doctor blades, and the web itself helps maintain their physical properties and extends their service life. This means less frequent replacement of these consumable parts, leading to significant cost savings and reduced downtime.

In sheetfed offset printing, while heat exposure can vary, low-heat LED UV curing still offers advantages. It minimizes thermal stress on the paper or board, reducing the likelihood of curling or warping, especially when printing on heavier stocks or coated materials. The reduced heat generation also means less thermal expansion within the press machinery, potentially leading to more stable registration and a longer lifespan for critical components like bearers and bearings.

Extending Component Lifespan

The physical components of a printing press are directly impacted by heat. Rollers, both inking and transport, are made from various elastomers. Excessive heat can cause these materials to harden, crack, or lose their resilience. Low-heat LED UV curing drastically reduces this thermal degradation, allowing rollers to maintain their optimal performance characteristics for much longer periods.

Blankets in offset and flexographic printing are also sensitive to heat. Prolonged exposure can lead to premature hardening and a loss of tack, affecting ink transfer. By minimizing heat, LED UV curing helps preserve the flexibility and performance of blankets, extending their usable life.

Furthermore, the mechanical precision of a printing press relies on the stability of its components. Heat causes materials to expand and contract, which can lead to minute shifts in alignment. This is particularly problematic for high-precision printing processes. Low-heat LED UV curing minimizes these thermal fluctuations, helping to maintain the mechanical accuracy of the press and reducing wear on gears, bearings, and other moving parts.

Reduced Substrate Degradation

Beyond the press itself, the printing substrate is also vulnerable. Many inks and coatings used in printing contain polymers that cure under UV light. If the curing process involves excessive heat, these polymers can be stressed, leading to brittleness or discoloration over time. Low-heat LED UV curing promotes a more gentle and efficient polymerization, resulting in a more stable and durable cured ink or coating layer. This translates to better rub resistance, scratch resistance, and overall longevity of the printed product.

The Environmental and Economic Argument

While the primary focus is on press longevity, the economic and environmental benefits of low-heat LED UV curing are also compelling. Reduced energy consumption directly lowers operating costs. The elimination of mercury lamps also removes hazardous waste disposal issues associated with their eventual end-of-life. Furthermore, the extended lifespan of press components and consumables means less waste material generated from replacements, contributing to a more sustainable printing operation.

Transitioning to LED UV Curing

The integration of LED UV curing systems into existing narrow web, flexographic, and offset presses is becoming increasingly feasible. Retrofitting options are available, allowing printers to upgrade their current machinery without a complete overhaul. Careful consideration of wavelength compatibility with specific inks and coatings is important during the transition. However, the investment in an LED UV system, especially a low-heat variant, can yield significant returns through reduced maintenance, fewer component replacements, and the ability to print on a wider array of substrates.

Conclusion: A Smarter Path to Print Longevity

The adoption of low-heat LED UV curing technology is more than just an upgrade; it’s a strategic move towards enhanced operational efficiency and extended press life. By mitigating the damaging effects of excessive heat on substrates, inks, and critical press components, printers in the label, flexographic, and offset sectors can significantly reduce wear and tear. This leads to lower maintenance costs, less downtime, and a more robust, reliable printing operation. Embracing this advanced curing technology is a clear path to ensuring the long-term productivity and profitability of your printing investments.