In the competitive world of label printing, achieving exceptional print resolution is paramount. For narrow-web digital label printing systems, this pursuit is directly linked to delivering crisp text, vibrant imagery, and intricate details that capture consumer attention. The integration of advanced technologies, particularly LED UV curing, plays a pivotal role in elevating this resolution. This article delves into the technical aspects and practical strategies for maximizing print sharpness in these demanding applications.

Understanding the Factors Influencing Digital Label Print Resolution

Print resolution, often measured in dots per inch (DPI), is a complex interplay of several elements. In digital label printing, the inkjet printhead technology is the primary determinant of droplet placement accuracy and size. Higher native DPI capabilities of the printhead allow for finer detail reproduction. However, this is only one piece of the puzzle.

The ink itself is another critical component. Ink viscosity, surface tension, and particle size all impact how the ink behaves on the substrate as it is deposited and cured. For optimal resolution, inks must be formulated to produce sharp, well-defined dots that do not bleed or spread excessively.

The substrate’s surface properties are equally important. Porosity, surface energy, and smoothness dictate ink absorption and spread. A highly absorbent or rough substrate can lead to ink feathering, diminishing sharpness. Conversely, non-absorbent substrates require inks with precise drying or curing characteristics.

The Role of Printheads in High-Resolution Narrow-Web Printing

Modern narrow-web digital presses utilize sophisticated inkjet printheads, often featuring drop-on-demand (DOD) technology. These printheads operate by precisely ejecting tiny ink droplets onto the substrate. The accuracy of this ejection, including the consistency of droplet size and trajectory, directly translates to image sharpness.

Continuous inkjet (CIJ) and valve jet technologies also exist, each with its own strengths. However, for high-resolution label printing, piezoelectric and thermal DOD printheads are prevalent. Piezoelectric printheads offer excellent jetting stability and are well-suited for a wide range of ink formulations, including UV-curable inks. Thermal DOD heads, while effective, can be limited by ink chemistry due to the heat involved.

The native DPI of the printhead is a foundational aspect. A printhead with a higher native DPI can physically place more dots within a given area. However, effective resolution is also achieved through techniques like greyscale printing, where different grey levels are simulated by varying the size or number of dots, allowing for smoother transitions and finer detail rendering even with lower native DPI heads.

Ink Formulation: The Foundation of Sharpness

The chemistry of the ink is a non-negotiable element in achieving high-resolution prints. For digital label printing, especially narrow-web applications, UV-curable inks are dominant due to their fast curing, durability, and versatility across various substrates.

The key to sharp resolution with UV inks lies in their polymerization process. When exposed to UV light, photoinitiators within the ink trigger a rapid chemical reaction, solidifying the ink almost instantaneously. This “pinning” effect prevents ink spread.

Key ink properties for high resolution include:

- Low Viscosity: While not always the sole factor, lower viscosity inks can sometimes allow for finer jetting and more controlled droplet formation.

- Optimized Pigment Dispersion: Uniformly dispersed, fine pigment particles are essential. Agglomerated pigments can lead to rougher ink films and reduced sharpness.

- Appropriate Photoinitiator System: The photoinitiators must efficiently absorb UV energy and initiate polymerization without introducing unwanted side reactions or excessive heat.

- Controlled Surface Tension: This affects how the ink wets and spreads on the substrate.

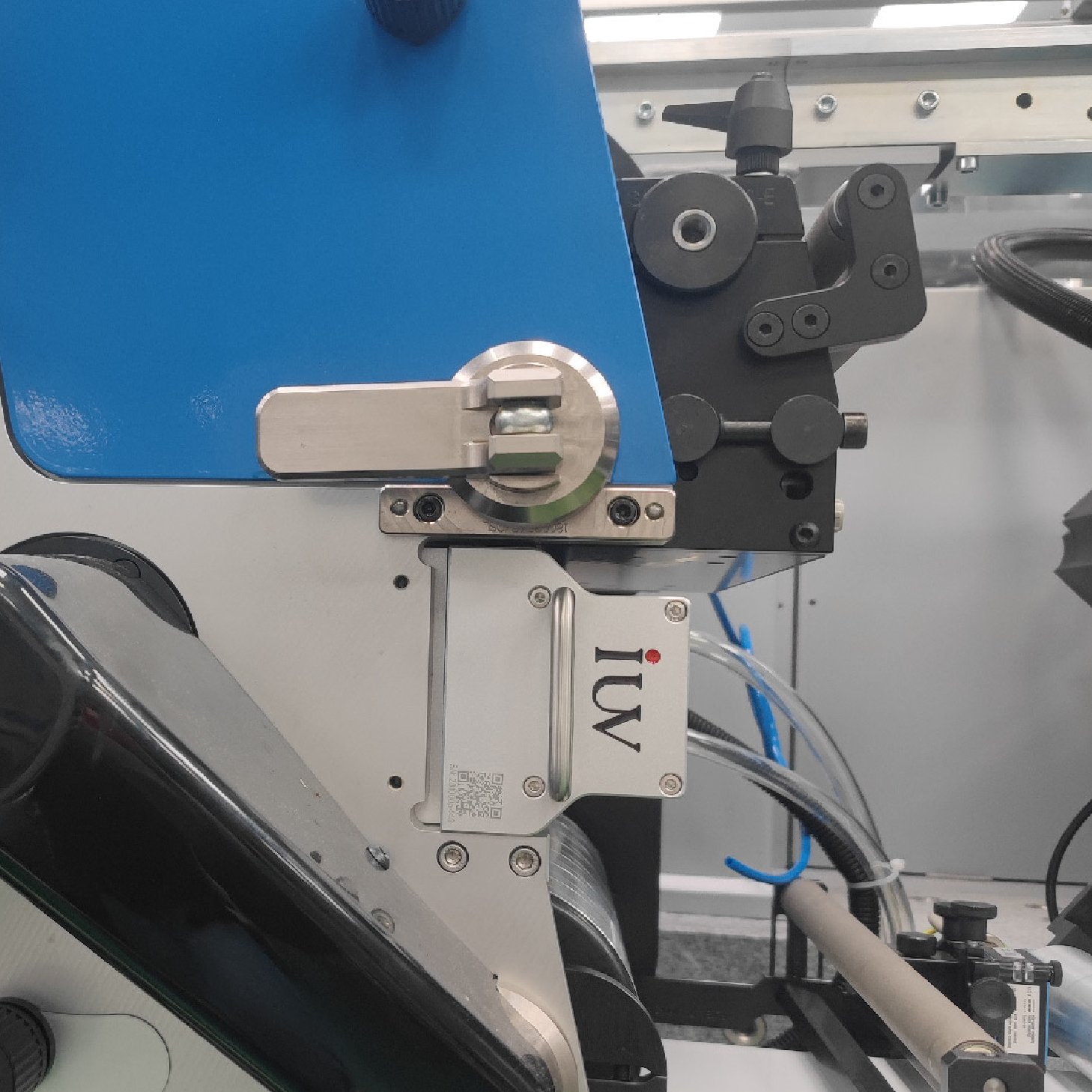

LED UV Curing: A Revolution in Sharpness and Efficiency

The advent of LED UV curing technology has profoundly impacted the ability to achieve superior print resolution in digital label printing. Unlike traditional mercury vapor lamps, LEDs offer a more controlled and targeted UV output.

Benefits of LED UV curing for resolution:

- Instant Curing and Pinning: LEDs emit UV light at specific wavelengths, enabling extremely rapid polymerization of UV-curable inks. This near-instantaneous curing prevents ink spread, ensuring sharp dot formation and clean edges. The “pinning” effect is significantly enhanced, locking the ink in place immediately after deposition.

- Reduced Heat Input: LEDs generate significantly less heat than mercury lamps. This is crucial for narrow-web printing, where heat can warp or damage sensitive substrates, leading to registration issues and reduced overall print quality. Lower heat input also means less drying or shrinking of the substrate, which preserves fine detail.

- Precise Wavelength Control: LEDs can be manufactured to emit specific UV wavelengths that are perfectly matched to the photoinitiator package in the ink. This leads to more efficient and complete curing, reducing the risk of uncured ink, which can compromise image quality and durability.

- Uniformity: Modern LED UV curing systems are designed to provide highly uniform irradiance across the entire web width. This consistent curing energy ensures that dots are cured evenly, contributing to uniform sharpness throughout the printed area.

- Durable, High-Contrast Prints: Complete and efficient curing results in a robust ink film that resists scratching and abrasion, maintaining the visual integrity and sharpness of the printed image over time.

Optimizing Substrate Interaction for Enhanced Resolution

The interaction between the ink and the substrate is a critical determinant of resolution. For narrow-web digital printing, especially with UV inks, selecting the right substrate is key.

- Coated vs. Uncoated: Coated substrates, such as those with a matte, silk, or gloss finish, generally offer superior print resolution. The coating provides a smoother, less porous surface, which minimizes ink absorption and spread. This allows the ink droplets to form well-defined dots.

- Surface Energy: The surface energy of the substrate influences how well the ink wets and adheres. A substrate with appropriate surface energy ensures that ink droplets spread to the desired extent, creating a solid dot without excessive feathering or beading. Corona or plasma treatment can be used to modify surface energy if needed.

- Smoothness: A smoother substrate surface allows for more consistent ink deposition and reduces the likelihood of ink bridging gaps between microscopic surface irregularities, which can degrade sharpness.

Process Control: The Unsung Hero of High Resolution

Beyond hardware and consumables, meticulous process control is essential for consistently achieving high print resolution in narrow-web digital label printing.

- Inkjet System Calibration: Regular calibration of the inkjet printheads ensures accurate droplet firing, consistent droplet size, and precise placement. This includes checks for clogged nozzles, firing voltage, and waveform optimization.

- Environmental Control: Temperature and humidity within the printing environment can affect ink viscosity, substrate behavior, and the curing process. Maintaining a stable environment minimizes these variables.

- Web Tension Control: Consistent and appropriate web tension is crucial for maintaining accurate registration and preventing substrate movement during printing and curing. Variations in tension can lead to image distortion and loss of sharpness.

- LED UV Curing Parameters: Fine-tuning the power output and exposure time of the LED UV curing system is vital. Insufficient curing leads to poor adhesion and potential smudging, while excessive exposure can cause substrate degradation or ink discoloration. The correct setting ensures optimal polymerization without negative side effects.

Achieving Fine Details: Combining Technologies for Success

The ultimate goal in narrow-web digital label printing is the ability to reproduce fine lines, small text, and intricate graphics with clarity. This is achieved by a holistic approach that integrates high-resolution printheads, advanced ink formulations, appropriate substrates, and optimized LED UV curing.

Consider a scenario where a label requires very small text (e.g., 4-point font) and fine line work. To achieve this with high fidelity:

- Printhead Selection: A printhead with a native resolution of 600 DPI or higher, capable of jetting very small droplet volumes, is desirable. Greyscale capabilities further enhance the ability to render subtle tones and transitions.

- Ink Choice: A specially formulated UV ink with fine pigment dispersion, optimized viscosity, and a fast-curing profile is necessary. The ink must be designed to maintain its shape upon deposition.

- Substrate Pairing: A smooth, coated label stock with controlled surface energy that promotes sharp dot formation will be the best choice.

- LED UV Curing Strategy: The LED UV system must be precisely calibrated to deliver rapid and complete curing immediately after ink deposition, effectively “freezing” the ink droplet in its intended position. The wavelength and intensity must perfectly match the ink’s photoinitiator package.

- Process Vigilance: Maintaining precise environmental controls, consistent web tension, and regular printhead calibration ensures that these optimized components work together flawlessly.

By carefully managing each of these elements, narrow-web digital label printing systems can overcome previous limitations and deliver print resolution that rivals or even surpasses traditional printing methods for many applications. The synergy between advanced digital printing technology and the precision of LED UV curing is the key to unlocking unparalleled sharpness and detail on every label.