Unlock Superior Print Quality: LED Curing for Adhesion and Gloss

In today’s competitive label printing market, achieving both exceptional adhesion and precise gloss control is paramount. Narrow web printers, whether using flexographic, offset, or other advanced printing methods, are constantly seeking ways to elevate their output. The solution lies in embracing cutting-edge curing technology. Specifically, LED UV curing systems offer a transformative approach, dramatically enhancing the performance of inks and coatings. This technology moves beyond traditional methods, providing printers with unprecedented control over critical print attributes.

The Science Behind Enhanced Adhesion with LED UV

Adhesion is the bedrock of a quality print. For labels, this means the ink must firmly bond to the substrate, resisting abrasion, chemicals, and environmental stress. Traditional UV curing relies on mercury vapor lamps, which emit a broad spectrum of UV light. While effective, these lamps can generate significant heat and offer less precise wavelength control.

LED UV curing systems, on the other hand, emit very specific, narrow bands of UV light. This targeted energy is precisely matched to the photoinitiators within UV inks and coatings. When these specific wavelengths hit the photoinitiators, they trigger a rapid polymerization process. This process creates a highly cross-linked ink film. The result is a robust molecular structure that adheres strongly to a wide range of substrates, including challenging plastics and foils.

The efficiency of LED curing means less energy is required to achieve full cure. This lower energy input also translates to less heat transferred to the substrate. For heat-sensitive materials commonly used in narrow web printing, this is a significant advantage. Reduced heat minimizes substrate distortion, preventing issues like edge lift or dimensional instability that can compromise final label integrity and adhesion.

Mastering Gloss Control with Precision LED Curing

Gloss is not just about aesthetics; it’s a crucial element of brand perception and product differentiation. Achieving a consistent, high-quality gloss finish, or a precisely controlled matte effect, can be challenging. LED UV curing systems provide the level of control necessary to master this aspect of print production.

The intensity and wavelength of LED lamps can be precisely modulated. This allows printers to fine-tune the curing process for different inks and varnishes. For high-gloss applications, a full, rapid cure ensures a smooth, uniform surface. This uniformity minimizes microscopic imperfections that scatter light, thus maximizing reflectivity and creating a brilliant shine.

Conversely, for matte finishes, the curing process can be adjusted to create a slightly more textured surface at the microscopic level. This controlled texture diffuses light, resulting in a sophisticated, non-reflective appearance. Unlike older methods that might rely on special matte varnishes or additives, LED curing allows for this control directly through the curing parameters, often with standard inks and coatings.

Advantages for Different Printing Processes

Flexographic Printing: In flexo, where raised plates transfer ink, precise ink transfer and setting are vital. LED curing enables near-instantaneous ink setting. This prevents ink spread and dot gain, preserving fine details and ensuring sharp print definition. The enhanced adhesion from LED curing also means flexo labels can withstand more demanding application environments.

Offset Printing (Sheetfed and Web): Offset printing demands excellent ink trapping and precise drying. LED UV curing systems provide rapid curing between printing units. This allows for faster press speeds and the ability to print multiple colors without smudging or ink transfer issues. The strong adhesion achieved with LED is a major benefit for offset labels, ensuring durability.

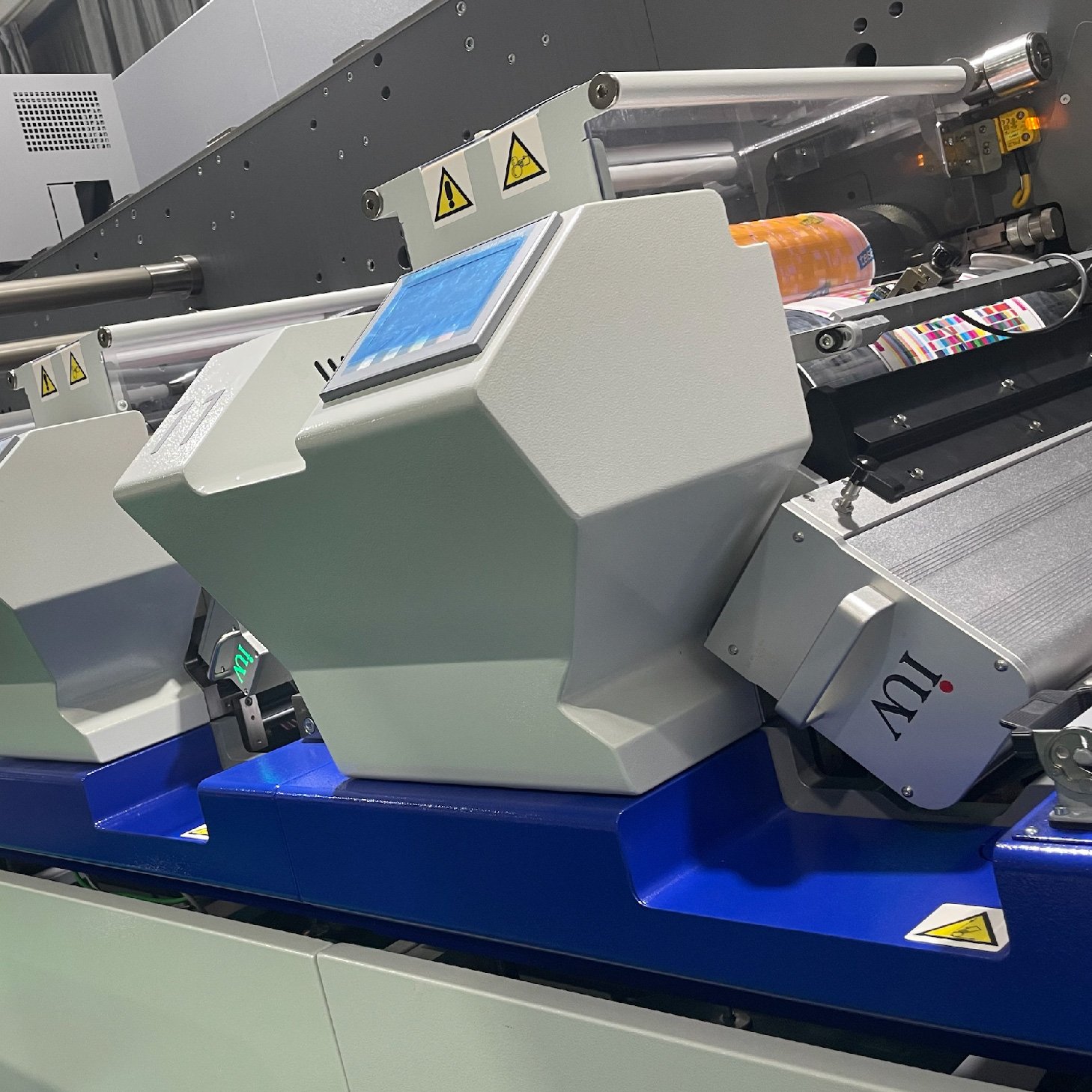

Narrow Web Printing: The narrow web sector, encompassing labels and flexible packaging, benefits immensely from LED UV technology. The compact nature of LED units makes them ideal for retrofitting onto existing presses. Their energy efficiency reduces operating costs. Crucially, the enhanced adhesion and gloss control directly contribute to producing premium labels that meet the high standards of brand owners. The ability to print on a wider array of substrates, including difficult-to-print films, opens new market opportunities for narrow web printers.

Optimizing Your Press for LED UV Curing

Implementing LED UV curing systems requires careful consideration. Understanding your inks and substrates is key. Different UV inks are formulated with specific photoinitiators that respond best to particular UV wavelengths. Ensure your LED system’s spectrum is optimized for the inks you use.

- Wavelength Selection: Choose LED systems with wavelengths that efficiently cure your specific ink formulations. Common wavelengths are in the 365nm, 385nm, 395nm, and 405nm ranges.

- Irradiance Levels: The intensity of the UV light (irradiance) is critical. Higher irradiance leads to faster cure speeds. However, it must be balanced with the ink’s chemistry and substrate’s heat sensitivity.

- Cooling Systems: While LEDs generate less heat than mercury lamps, effective cooling is still necessary to maintain optimal performance and lamp longevity, especially at high power outputs.

- Process Control: Implementing robust process control measures is vital. Monitoring UV output and temperature ensures consistent results across print runs.

The Future of Print: Energy Efficiency and Sustainability

Beyond performance, LED UV curing is a more sustainable choice. These systems consume significantly less energy than traditional mercury vapor lamps, leading to lower electricity bills and a reduced carbon footprint. They also contain no hazardous mercury, simplifying disposal and contributing to a greener printing operation.

As the demand for high-quality, durable, and aesthetically pleasing labels continues to grow, embracing LED UV curing systems is no longer just an option—it’s a strategic imperative for narrow web printers. By mastering adhesion and gloss control, you unlock new levels of print excellence and secure a competitive edge in the market.