High-speed flexographic printing operations are constantly seeking ways to boost efficiency and reduce costs. One significant area for improvement lies in the curing process. Traditional UV curing systems, while effective, can be energy-intensive. The advent of LED UV curing technology presents a compelling solution, offering substantial energy efficiency gains without compromising print quality or speed.

Understanding UV Curing in Flexography

Flexographic printing, often referred to as flexo, is a widely used method for printing on a variety of substrates, including films, foils, and paper. It utilizes a flexible relief plate to transfer ink onto the substrate. For many applications, especially in narrow-web printing for labels and packaging, UV curable inks are the preferred choice. These inks contain photoinitiators that, when exposed to ultraviolet (UV) light, undergo a rapid polymerization process, transforming from a liquid to a solid state. This instant curing allows for faster printing speeds and immediate handling of the printed material.

The Energy Demands of Traditional UV Curing

Conventional UV curing systems typically employ mercury vapor lamps. These lamps generate UV light by passing an electric current through mercury vapor. While they are robust and have been the industry standard for decades, they come with several drawbacks, particularly concerning energy consumption.

Mercury lamps operate at high temperatures and require a warm-up period before reaching optimal output. They also emit a broad spectrum of light, much of which is in the infrared range, generating significant heat. This heat not only contributes to energy waste but can also affect the substrate, potentially causing shrinkage or deformation, especially with heat-sensitive materials common in label printing. Furthermore, mercury lamps have a finite lifespan and need regular replacement, adding to operational costs. Their disposal also presents environmental considerations.

The Rise of LED UV Curing Technology

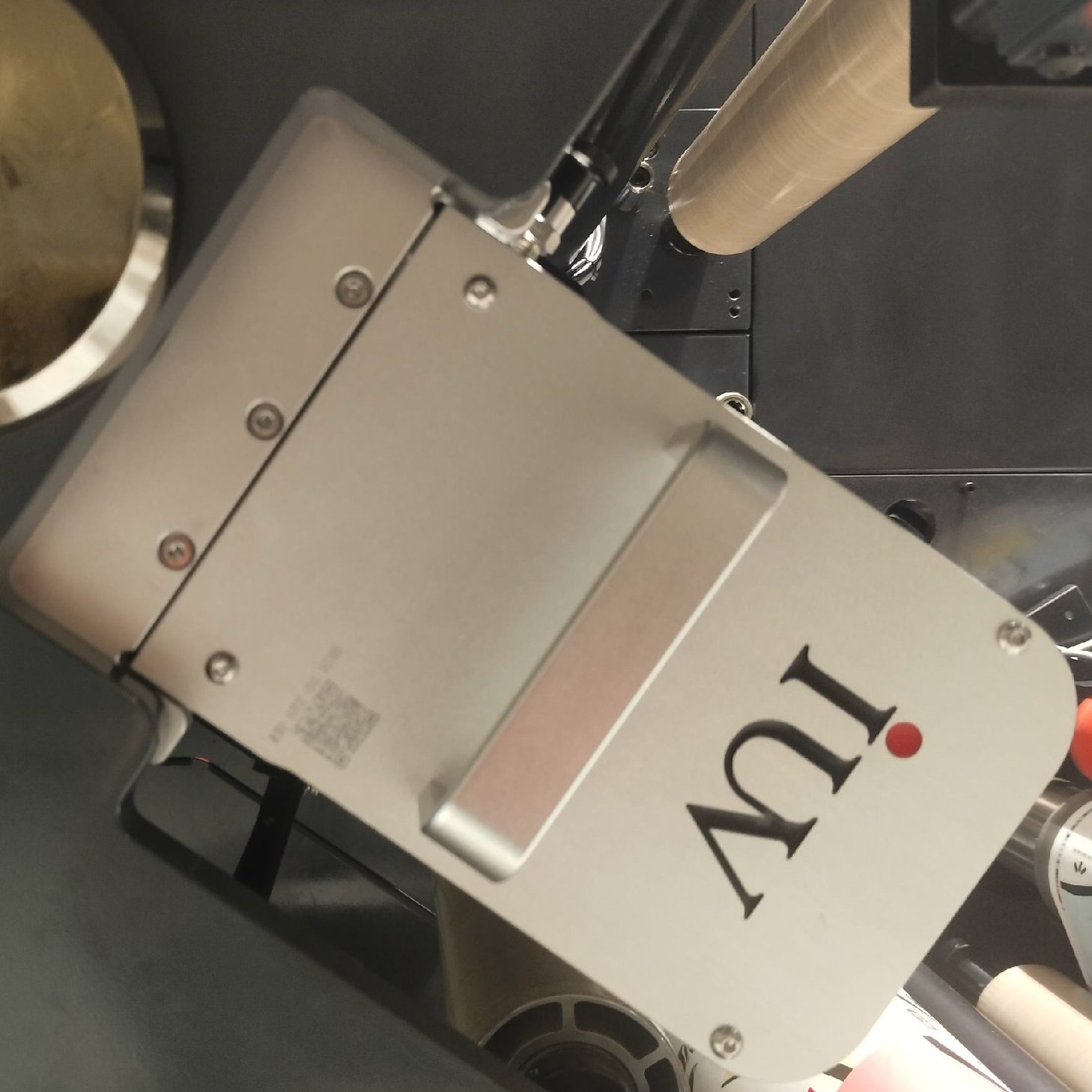

LED UV curing utilizes Light Emitting Diodes (LEDs) to produce UV light. Unlike mercury lamps, LEDs are solid-state devices that emit light within a narrow, specific wavelength range, precisely tuned to the absorption spectrum of the photoinitiators in the UV inks. This targeted emission is a key factor in their superior energy efficiency.

The benefits of this focused emission are multifaceted. Firstly, LEDs generate very little heat. This means less energy is wasted as thermal radiation, and the need for extensive cooling systems is significantly reduced. Substrates remain cooler, preserving their integrity. Secondly, LEDs achieve their full UV output instantaneously. There is no warm-up or cool-down period, allowing for immediate on/off switching. This capability is particularly advantageous in high-speed flexo operations where presses may be started and stopped frequently.

Quantifying Energy Efficiency Gains

The energy savings realized by switching from traditional mercury UV lamps to LED UV curing systems can be substantial. Studies and real-world implementations have shown reductions in energy consumption ranging from 50% to 80%. This significant decrease can be attributed to several factors:

- Lower Power Consumption: LEDs operate at much lower wattages compared to mercury lamps for equivalent UV output. A typical LED system might consume a fraction of the power required by a comparable mercury lamp setup.

- No Standby Power Loss: Since LEDs turn on and off instantly, they consume no power when the press is idle or when UV curing is not required for a particular print station. Mercury lamps, on the other hand, often require continuous operation or a prolonged warm-up, leading to wasted energy during downtime.

- Reduced Ancillary Cooling: The minimal heat output from LEDs significantly reduces the need for power-hungry cooling systems, which are often essential for managing the heat generated by mercury lamps.

- Targeted Wavelengths: By emitting only the specific wavelengths needed to cure the ink, LEDs avoid the energy loss associated with producing unnecessary light spectrums.

Impact on High-Speed Flexo Operations

For high-speed flexographic printing, particularly in narrow-web applications like label and flexible packaging production, these energy savings translate directly into improved profitability. Reduced electricity bills are a direct operational cost saving. Beyond that, the efficiency gains contribute to a more sustainable printing process.

The ability of LED UV to cure instantly at high speeds means that print speeds are not limited by the curing technology. This allows printers to maximize the throughput of their presses. Furthermore, the consistent UV output from LEDs ensures reliable and repeatable curing, leading to improved print quality and reduced waste due to curing defects. The longer lifespan of LEDs also means less downtime for lamp replacement and maintenance, further contributing to overall operational efficiency.

Considerations for Implementation

When considering the transition to LED UV curing in a high-speed flexo environment, several factors warrant attention. The initial investment in LED UV systems can be higher than for traditional mercury lamps. However, the long-term savings in energy, maintenance, and potential substrate savings often lead to a rapid return on investment.

It is also crucial to ensure that the LED UV system’s wavelength output is precisely matched to the photoinitiator package in the UV inks being used. Ink manufacturers offer specialized formulations designed for LED curing, ensuring optimal performance. Compatibility with existing press configurations and substrate types should also be evaluated.

Beyond Energy: Other Advantages of LED UV

While energy efficiency is a primary driver, LED UV curing offers several other compelling advantages for flexographic printers:

- Environmental Benefits: Reduced energy consumption directly lowers the carbon footprint of the printing operation. The absence of mercury also eliminates hazardous waste disposal issues associated with mercury lamps.

- Improved Print Quality: The consistent and focused UV output leads to more uniform curing, resulting in sharper dots, better color consistency, and enhanced print durability.

- Substrate Versatility: The low heat output allows for the printing on a wider range of heat-sensitive substrates, including thin films and plastics, which might be challenging with mercury UV systems.

- Reduced Maintenance: LEDs have a significantly longer operational life (often 20,000-30,000 hours or more) compared to mercury lamps (typically 1,000-2,000 hours). This translates to less downtime for replacements and associated labor costs.

- Instant On/Off: This feature not only saves energy but also reduces waste during job setup and changeovers, as the UV lamps don’t need time to warm up or cool down.

- Compact Design: LED UV systems are often more compact than traditional mercury lamp setups, allowing for easier integration into existing press lines.

The Future of Curing in Flexography

The trend towards greater sustainability and operational efficiency in the printing industry points to a continued adoption of LED UV curing technology. For high-speed flexographic operations, especially those involved in narrow-web label and packaging printing, the energy efficiency gains are undeniable and contribute significantly to cost reduction and environmental responsibility. As ink formulations continue to evolve and LED technology advances, the advantages will only become more pronounced, solidifying LED UV curing as a cornerstone of modern flexographic printing.