Enhancing Label and Narrow Web Printing with LED UV Curing Systems

In the competitive world of label and narrow web printing, achieving high-quality output efficiently is paramount. Embracing advanced curing technologies like LED UV systems offers numerous advantages—improved energy efficiency, faster production speeds, and enhanced print quality. This shift not only benefits plant operations but also helps printers meet the rising demands for sustainable and cost-effective solutions.

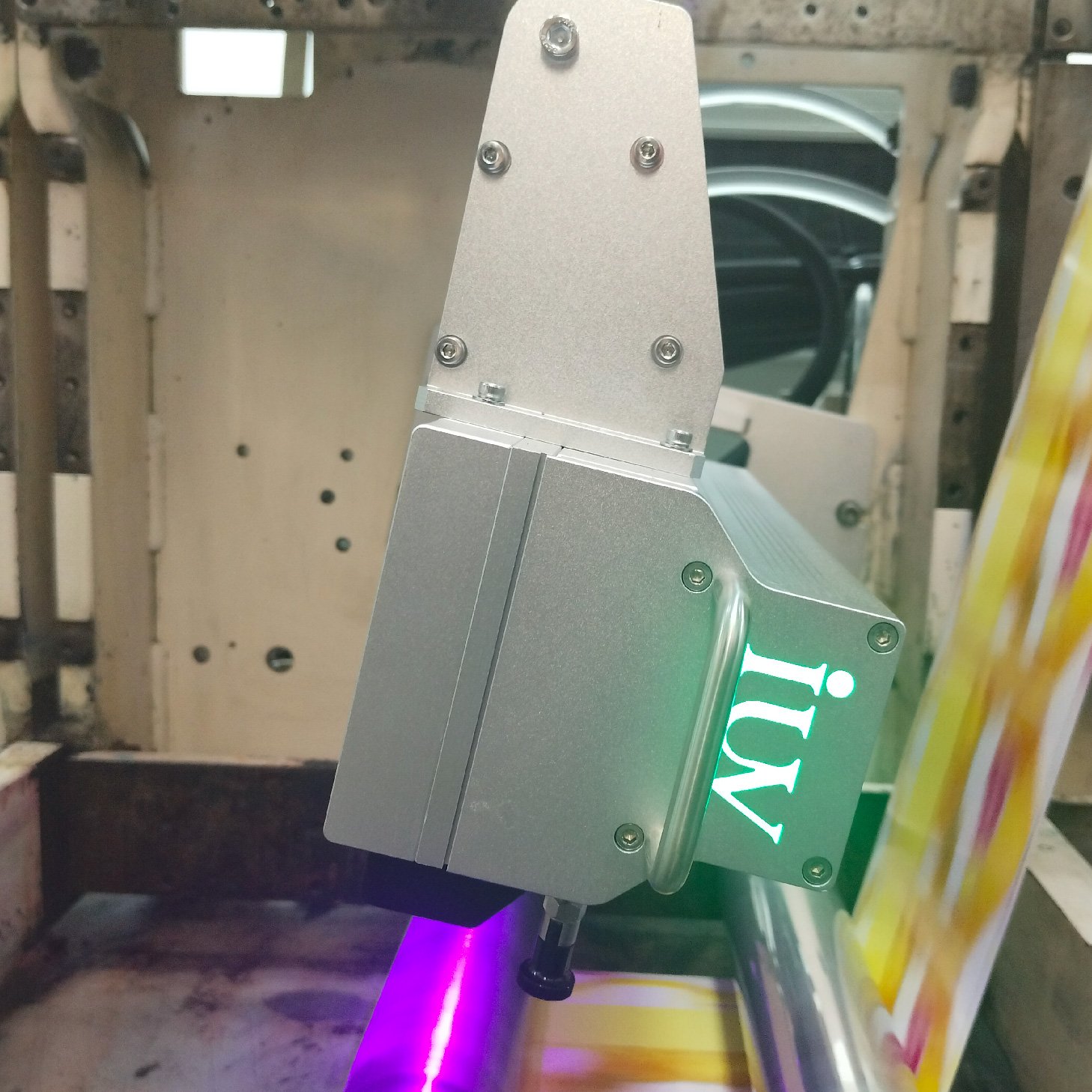

The Role of LED UV Curing in Flexo, Letterpress, and Offset Printing

LED UV curing technology brings a significant transformation to various print processes, including flexo, letterpress, and offset printing, especially on label substrates. Unlike traditional UV systems, LED UV lamps use light-emitting diodes that emit specific wavelengths, leading to faster cure times and lower heat generation. This approach is particularly well suited for delicate substrates used in label and narrow web printing, such as paper, film, and foil.

The benefits extend to enhanced productivity—printers can achieve quicker turnaround times, minimize ink drying times, and reduce energy consumption. LED UV systems also exhibit lower maintenance costs because of their longer lifespan and fewer replacement parts, ensuring consistent operation with minimal downtime.

Superior Energy Efficiency and Sustainability

Switching to LED UV curing dramatically reduces energy consumption. Traditional UV lamps require high-voltage, power-hungry systems that produce significant heat, leading to higher operating costs and increased cooling requirements. In contrast, LED UV systems operate at lower voltages, converting energy more effectively into curing ultraviolet light.

This efficiency translates into reduced electricity bills and a smaller carbon footprint. For label printing operations, which often run continuous shifts, these savings quickly add up. Additionally, the reduced heat emission protects sensitive substrates and reduces the need for elaborate cooling systems, leading to a more sustainable workflow.

Enhanced Productivity Gains

LED UV curing delivers rapid curing times, often in milliseconds, which accelerates label production lines. The ability to instantly lock in inks and coatings means less waiting time and higher throughput capacity. For narrow web and flexo printers, this means faster job turnaround while maintaining consistent print quality.

Moreover, LED UV systems are capable of curing multiple inks and coatings in a single pass. This capability supports more complex labels with metallic finishes, tactile coatings, and variable data without sacrificing speed. The quick start-up times and instant curing reduce job changeover time, making just-in-time production a viable reality.

Improving Color Quality and Ink Adhesion

LED UV curing offers precise control over curing intensity, leading to vibrant colors and sharp detail reproduction. Accurate curing ensures proper ink adhesion—particularly important when printing on flexible substrates or films used in labels. It also minimizes issues like print distortion, ink picking, and blocking, resulting in pristine, durable labels.

The instant curing process stabilizes ink films quickly, preventing smudging or smearing during handling or finishing processes. This results in cleaner, more consistent quality, which is crucial for branding and compliance labels requiring sharp graphics or fine text.

Compatibility with Various Printing and Coating Inks

One of the advantages of LED UV systems is their compatibility with a broad range of inks—UV-curable inks, UV silicones, and specialty coatings. This flexibility allows printers to explore new effects, textures, and finishing options, all while enjoying energy savings and faster processing times.

In label production, this translates to the ability to print high-gloss finishes, matte textures, or holographic effects in a single pass. These finishing options can significantly elevate product appeal, especially in competitive markets like cosmetics, spirits, or health products.

Managing Substrate Flexibility and Heat-Sensitive Materials

Exposure to heat from traditional UV curing can sometimes damage delicate label substrates. LED UV curing produces minimal heat, making it ideal for printing on heat-sensitive materials such as thin films, holographic foils, or specialty papers.

This attribute broadens design possibilities and allows for the printing of high-quality, premium labels on diverse substrates. Companies can innovate with new materials without the risk of warp, curl, or other heat-induced defects, ensuring consistent quality across varied runs.

Simplified Maintenance and Cost Savings

LED UV systems are simpler in design compared to traditional mercury vapor lamps, which require warm-up times and frequent replacements. LEDs have a significantly longer lifespan, often lasting tens of thousands of hours, and do not contain hazardous materials like mercury.

This translates into lower maintenance expenses and less environmental impact. The reduced downtime helps maintain high productivity levels, ensuring that press schedules remain tight and delivery deadlines are met consistently.

Future-Proofing Label Printing with LED UV Technology

Investing in LED UV curing is a strategic move for label and narrow web printers aiming to stay competitive. The technology supports eco-friendly manufacturing, reduces operational costs, and offers the agility needed to keep pace with market evolution.

As industry standards shift toward sustainability, regulatory compliance, and high-speed production, LED UV systems position printing operations at the forefront of innovation. They enable printers to deliver vibrant, durable labels efficiently, meeting both consumer expectations and regulatory demands.

Conclusion

LED UV curing systems redefine what’s possible in label, flexo, and narrow web printing. With their combination of energy efficiency, rapid curing, substrate compatibility, and lower maintenance costs, they represent a significant step toward greener, more productive printing solutions. Embracing this technology empowers printers to produce high-quality labels efficiently, ensuring they remain competitive in a fast-evolving marketplace.