Modern label production demands efficiency and versatility. Narrow web printers, in particular, are under pressure to deliver high-quality labels faster and more affordably. Traditional UV curing systems have long been a staple in this environment. However, these mercury-based lamps come with significant drawbacks. They consume a lot of energy, generate substantial heat, and require frequent replacement. This leads to increased operational costs and downtime.

The evolution of UV LED curing technology presents a compelling solution. Retrofitting existing narrow web presses with UV LED systems offers a pathway to substantial cost savings and enhanced performance. This upgrade is not merely a technological advancement; it’s a strategic investment for label converters. It positions businesses to meet current market demands and future challenges.

The Limitations of Traditional UV Curing

For decades, mercury vapor lamps powered UV curing in label printing. These lamps emit UV light across a broad spectrum. This broad spectrum allows them to cure a variety of inks and coatings effectively. However, their operational inefficiencies are well-documented.

Mercury lamps require a warm-up period before reaching peak intensity. They also cool down slowly. This impacts press start-up and job changeover times. Their energy consumption is notably high. A significant portion of this energy is converted into heat, not UV light. This excess heat can stress sensitive substrates like thin films and delicate papers. It can also lead to ink dot gain and affect print quality.

The lifespan of mercury lamps is limited, typically around 1000-2000 hours. Replacing these lamps is a recurring expense. The disposal of spent mercury lamps also presents environmental and regulatory challenges. Furthermore, the broad spectrum emission can cause unwanted degradation of certain inks or coatings over time.

The Rise of UV LED Curing Technology

UV LED (Light Emitting Diode) curing technology represents a paradigm shift. LEDs emit UV light within a narrow, specific wavelength. This targeted emission is highly efficient. It focuses energy precisely where it’s needed for curing.

The benefits of UV LED are manifold. They offer instant on/off functionality. This eliminates warm-up and cool-down delays. This significantly reduces press downtime during setup and job changes. Energy consumption is dramatically lower compared to mercury lamps. LEDs convert a much higher percentage of electrical energy into UV light. This means less wasted energy and reduced heat generation.

The operational temperature of UV LED systems is considerably lower. This allows for the safe curing of heat-sensitive substrates. It also minimizes ink dot gain and preserves fine detail. The lifespan of UV LEDs is exceptionally long, often exceeding 20,000 hours. This drastically reduces replacement frequency and associated costs. Moreover, UV LED systems are mercury-free. This simplifies disposal and aligns with environmental sustainability goals.

The Economics of UV LED Retrofitting

The initial investment in UV LED retrofitting can seem substantial. However, a detailed cost-benefit analysis reveals its economic viability. The return on investment (ROI) is often realized within a relatively short period.

Consider the direct cost savings. Reduced energy bills are a primary driver. By switching to LEDs, printers can see significant reductions in electricity consumption. The extended lifespan of LEDs means fewer lamp replacements. This saves on both the cost of the lamps and the labor involved in changing them.

Reduced waste is another economic benefit. The lower heat output of LEDs minimizes substrate deformation and ink issues. This leads to fewer rejected jobs and less material waste. The faster curing speeds often enabled by UV LEDs can also increase press throughput. Higher output means more jobs completed in the same timeframe, boosting revenue.

Furthermore, the ability to print on a wider range of substrates opens new market opportunities. Curing on thin films or sensitive papers without degradation can differentiate a label converter. This allows for the production of higher-margin specialty labels.

Retrofitting Considerations for Narrow Web Presses

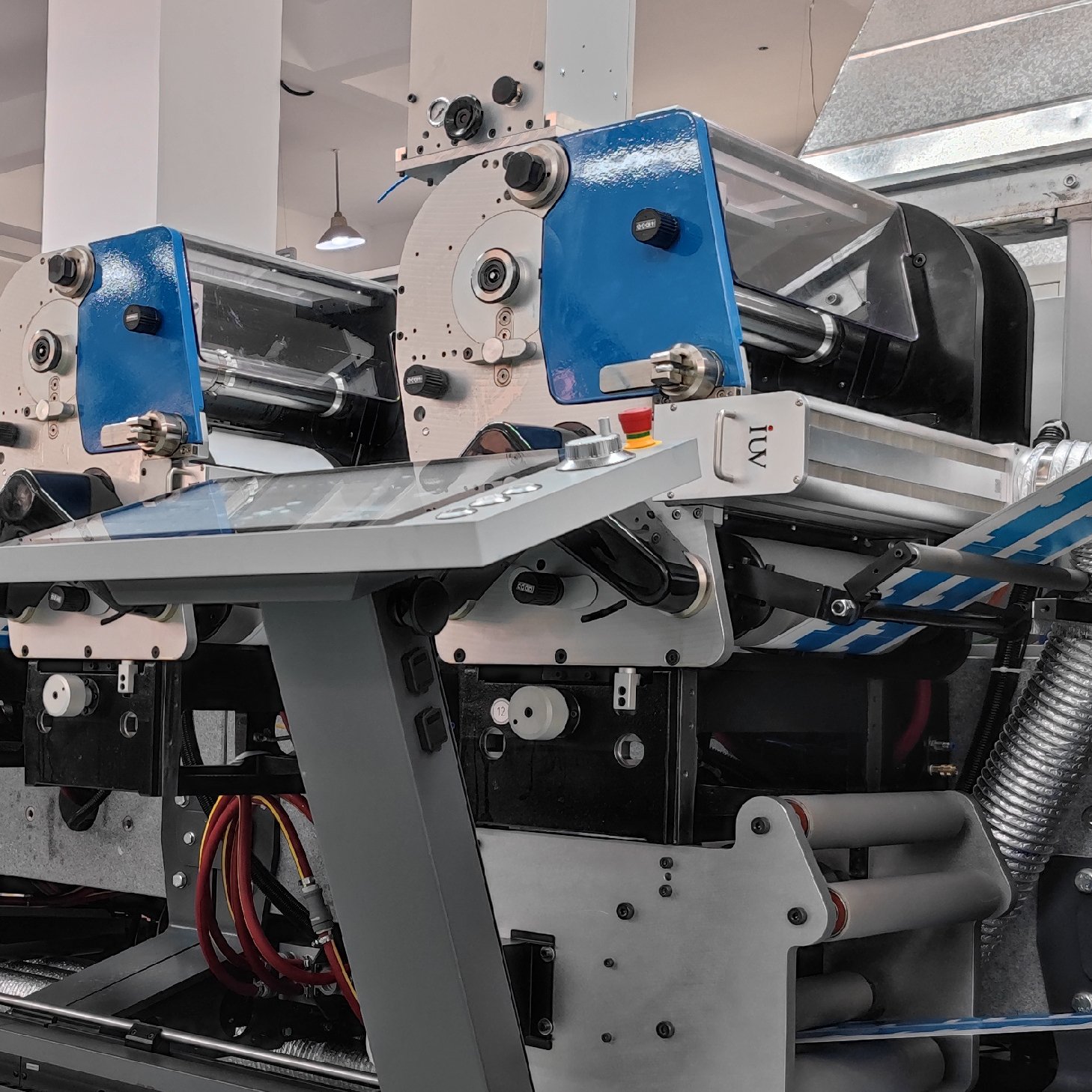

Retrofitting a narrow web flexographic or offset press with UV LED curing requires careful planning. Several technical factors need consideration to ensure seamless integration and optimal performance.

1. Wavelength Selection: UV LED systems are available in various wavelengths. The most common for UV curing are UV-A (365 nm, 395 nm) and UV-B (315 nm). The choice depends on the specific inks, coatings, and varnishes being used. Manufacturers provide guidelines, but testing with your chosen consumables is highly recommended. Ensuring compatibility is crucial for achieving full cure and desired properties.

2. Installation Space and Integration: Narrow web presses have limited space. The dimensions of the UV LED curing unit must be carefully measured. Retrofit systems are designed to be compact. They must fit within the existing press structure, often between print stations or at the end of the press. Proper mounting and integration with the press controls are essential.

3. Power Requirements: UV LED systems require a stable electrical supply. The power output of the chosen LED unit must be matched to the press’s electrical capacity. It’s important to ensure the press’s electrical infrastructure can support the new load without issues.

4. Cooling and Ventilation: While LEDs generate less heat than mercury lamps, they still produce some. Adequate ventilation is necessary to dissipate this heat. Most LED curing units have integrated cooling systems. However, ensuring proper airflow around the unit is important for longevity and consistent performance.

5. Curing Intensity (Irradiance) and Dose: Irradiance refers to the power density of UV light delivered to the substrate, measured in W/cm². Dose is the total amount of UV energy delivered, calculated as Irradiance x Exposure Time. Achieving the correct UV dose is critical for full cure. The width of the LED array and the press speed will determine the exposure time. The system’s irradiance must be sufficient for the specific ink/coating chemistry at the desired press speed.

6. Substrate Compatibility: As mentioned, UV LEDs are ideal for heat-sensitive substrates. However, it’s still important to consider how the specific substrate will interact with the chosen wavelength and curing intensity. Testing different substrates with your chosen LED system and inks/coatings is always advisable.

Advantages for Different Printing Processes

The benefits of UV LED retrofitting extend across various label printing methods.

For Flexographic Printing: Flexo presses are workhorses in narrow web label production. UV LED curing offers faster drying times between stations. This allows for higher printing speeds. It enables the use of thicker ink laydowns without smearing. The precision of LED curing also contributes to sharper print definition and better ink trapping. This is particularly valuable for intricate graphics and fine text common in label design.

For Offset Printing (Narrow Web): Offset label printing often demands precise ink control. UV LED curing provides instant curing, preventing ink spread. This maintains the fidelity of fine dots and sharp edges. It allows for immediate handling of printed sheets or rolls, increasing workflow efficiency. The reduced heat also benefits the transfer of ink to various substrates.

For Digital Label Printing: While many digital presses come with integrated UV or EB curing, retrofitting older digital or hybrid presses with UV LED can offer improvements. It allows for faster curing of digital inks and overprint varnishes. This can increase the speed of finishing processes. It also provides more consistent curing across different print runs.

Beyond Cost Savings: Enhanced Capabilities

The decision to retrofit with UV LED extends beyond simple cost reduction. It unlocks new production capabilities and enhances overall competitiveness.

Environmental Sustainability: The move to mercury-free UV LED technology aligns with growing industry demand for eco-friendly practices. Reduced energy consumption also lowers a printer’s carbon footprint.

Improved Print Quality: The precise control offered by UV LEDs leads to sharper images, finer details, and more consistent ink laydown. This translates to higher quality labels that better represent brand aesthetics.

Wider Application Range: The ability to print on heat-sensitive substrates opens doors to new markets and product types. This includes shrink sleeves, heat-sensitive films, and delicate papers.

Enhanced Productivity: Reduced downtime, faster curing, and the potential for higher press speeds all contribute to increased overall productivity. More labels produced in less time means greater profitability.

Workplace Safety: The absence of mercury and the reduction in heat contribute to a safer working environment for press operators.

Conclusion: A Strategic Investment

The retrofitting of narrow web presses with UV LED curing technology is more than an upgrade; it’s a strategic imperative for label manufacturers aiming for cost-effectiveness and market leadership. By understanding the limitations of traditional mercury lamp systems and embracing the advanced capabilities of UV LEDs, businesses can achieve significant operational efficiencies. Reduced energy consumption, extended lamp life, lower waste, and enhanced print quality are just some of the tangible benefits.

Careful consideration of wavelength, integration, power, and curing parameters ensures a successful retrofit. The advantages span flexographic, offset, and digital printing processes. Ultimately, UV LED retrofitting empowers label converters to meet evolving customer demands, embrace sustainable practices, and secure a competitive edge in the dynamic label production landscape. This technological leap is a prudent investment in future growth and profitability.