Choosing the right curing technology is a big decision for any flexographic printer. For years, traditional UV lamps were the standard. Now, LED curing systems are gaining significant traction. Both have their strengths and weaknesses, especially in narrow web printing for labels and packaging. Understanding these differences is key to optimizing your print process and your bottom line.

Traditional UV lamps, often mercury-based, have been the workhorse of UV curing for decades. They provide a broad spectrum of UV light, which works well with most conventional UV-curable inks and coatings. Installation is generally straightforward, and the initial equipment cost can be lower than that of LED systems. These lamps are robust and have a long history of reliable performance in various printing environments, including offset and flexo.

However, traditional UV lamps come with several drawbacks. They generate a lot of heat, which can be problematic for heat-sensitive substrates like thin films or some papers. This heat also requires significant energy consumption, leading to higher electricity bills. Furthermore, traditional UV lamps have a relatively short lifespan and their UV output degrades over time, requiring frequent replacement to maintain consistent curing quality. The lamps also contain hazardous materials, posing disposal challenges.

The intense heat from traditional UV lamps can also affect ink viscosity and the overall print quality, sometimes leading to issues like ink misting or substrate distortion. Achieving optimal cure can be a balancing act, as overexposure to heat can damage the substrate, while underexposure leads to incomplete curing, resulting in poor rub resistance and other quality defects.

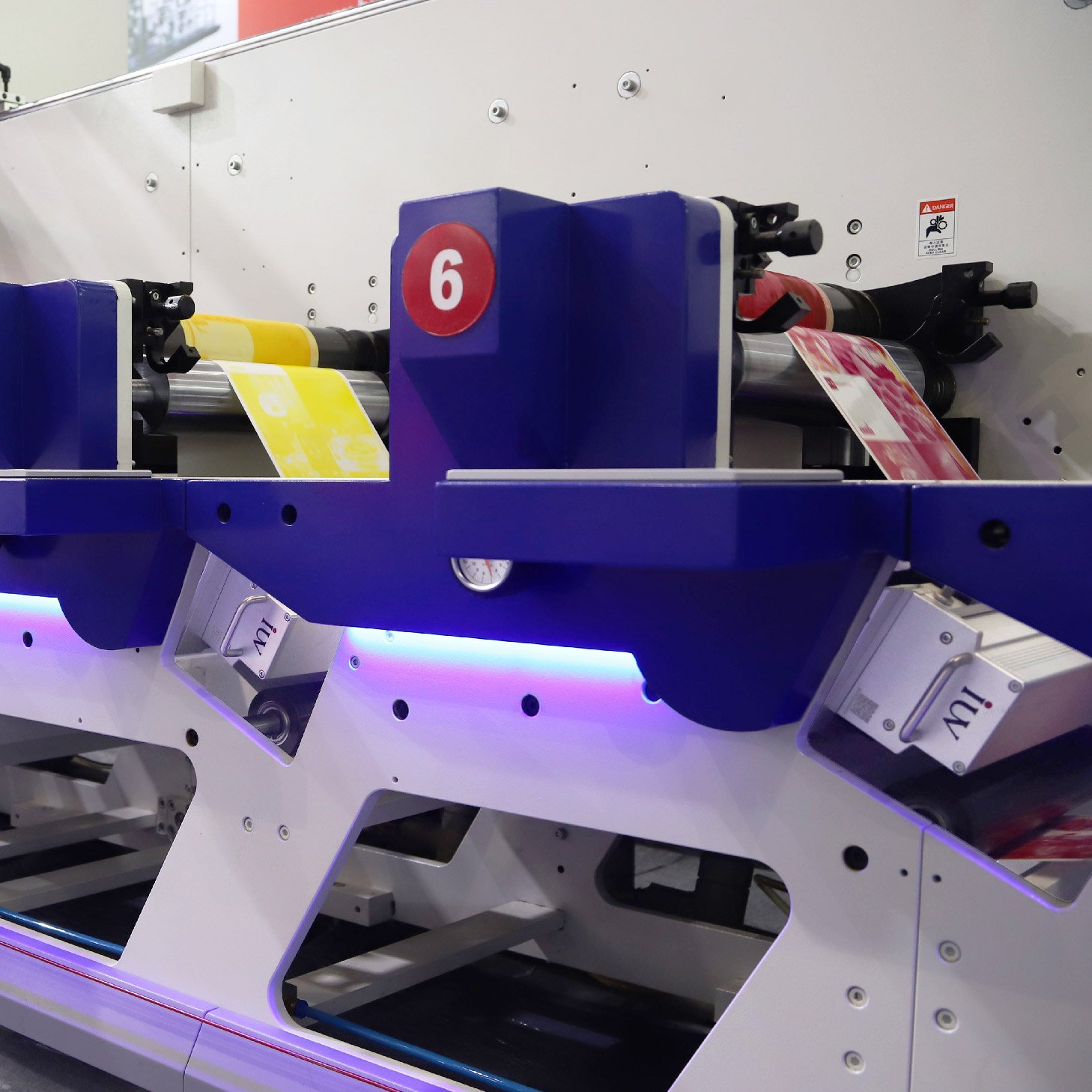

In contrast, LED curing systems offer a more modern and efficient approach. LEDs emit UV light within a very narrow wavelength band, typically 365 nm, 385 nm, 395 nm, or 405 nm. This targeted wavelength can be precisely matched to specific UV-curable inks and coatings designed for LED curing. This precision is a significant advantage.

One of the most compelling benefits of LED curing is its significantly lower heat output. This allows printers to run a wider range of substrates, including delicate and heat-sensitive materials, without concern for thermal damage. The reduced heat also contributes to a more stable printing environment, leading to better print registration and overall consistency.

Energy efficiency is another major win for LEDs. They consume far less power than traditional UV lamps. This translates directly into lower operating costs and a reduced carbon footprint for your printing operation. The energy savings can be substantial, especially for printers running multiple machines or operating at high speeds.

LED curing systems also boast a much longer lifespan, often tens of thousands of hours, compared to the few thousand hours typical for traditional UV lamps. This dramatically reduces downtime and the costs associated with lamp replacement and maintenance. The consistent UV output from LEDs ensures reliable curing performance throughout their operational life, eliminating the need for frequent recalibration due to lamp degradation.

The precise wavelength control of LED systems also allows for optimized curing of specialized inks and coatings. Many new ink formulations are specifically designed to cure efficiently under LED light. This can lead to improved ink adhesion, better scratch and chemical resistance, and enhanced print durability. For label printing, where vibrant colors and robust finishes are essential, this precision is invaluable.

However, LED curing systems do have their own set of considerations. The initial investment cost for LED curing equipment can be higher than for traditional UV systems. While the long-term savings are significant, this upfront cost can be a barrier for some businesses.

It’s also important to note that not all UV inks and coatings are compatible with LED curing. Printers looking to switch to LED technology may need to invest in new ink sets or coatings specifically formulated for LED wavelengths. This transition requires careful planning and potentially reformulating existing jobs.

The narrow wavelength output of LEDs means that if you have legacy inks or coatings that were designed for a broader UV spectrum, they might not cure as effectively. This is why selecting the correct LED wavelength to match your ink chemistry is critical. For flexo applications in narrow web printing, this careful selection ensures optimal performance.

Maintenance for LED systems is generally simpler due to their solid-state nature and longer lifespan. There are no bulbs to replace, and they typically require less cooling. This can lead to reduced maintenance overhead and less frequent technician intervention.

When comparing the two technologies for flexographic applications, especially in the narrow web sector for labels and packaging, several factors stand out. For printers handling a variety of substrates, including sensitive ones, the low heat of LEDs is a major advantage. For those concerned with energy costs and operational efficiency, the energy savings of LEDs are compelling.

The consistency of cure is another point of differentiation. LEDs provide a uniform light output that doesn’t degrade as quickly as traditional lamps, leading to more predictable and repeatable results job after job. This consistency is vital for maintaining high-quality standards in label production.

The decision between LED and traditional UV curing often comes down to a balance of initial investment versus long-term operational benefits. While traditional UV lamps offer a lower entry price and broad compatibility with older ink systems, LED curing systems provide superior energy efficiency, reduced heat, longer lifespan, and optimized performance with modern ink technologies.

For flexographic printing, particularly in the demanding narrow web market, the trend is clearly moving towards LED curing. The technology’s ability to handle diverse substrates, reduce energy consumption, and deliver consistent, high-quality results makes it an attractive choice for businesses looking to modernize their operations and stay competitive. Evaluating your current printing needs, substrate usage, and ink formulations will guide you to the best choice for your specific flexo applications.