The label manufacturing industry is in constant pursuit of greater efficiency and faster turnaround times. For decades, traditional printing methods like flexography and offset lithography have dominated the market, especially for longer runs. These methods, while producing high-quality labels, often involve extensive setup times, plate making, and ink drying processes that can slow down production.

In recent years, the rise of digital printing has revolutionized the landscape, particularly for short to medium runs and variable data printing. However, early digital technologies often struggled with substrate versatility and speed, especially when compared to their analog counterparts. The need for rapid curing of inks without compromising speed or print quality became a critical challenge.

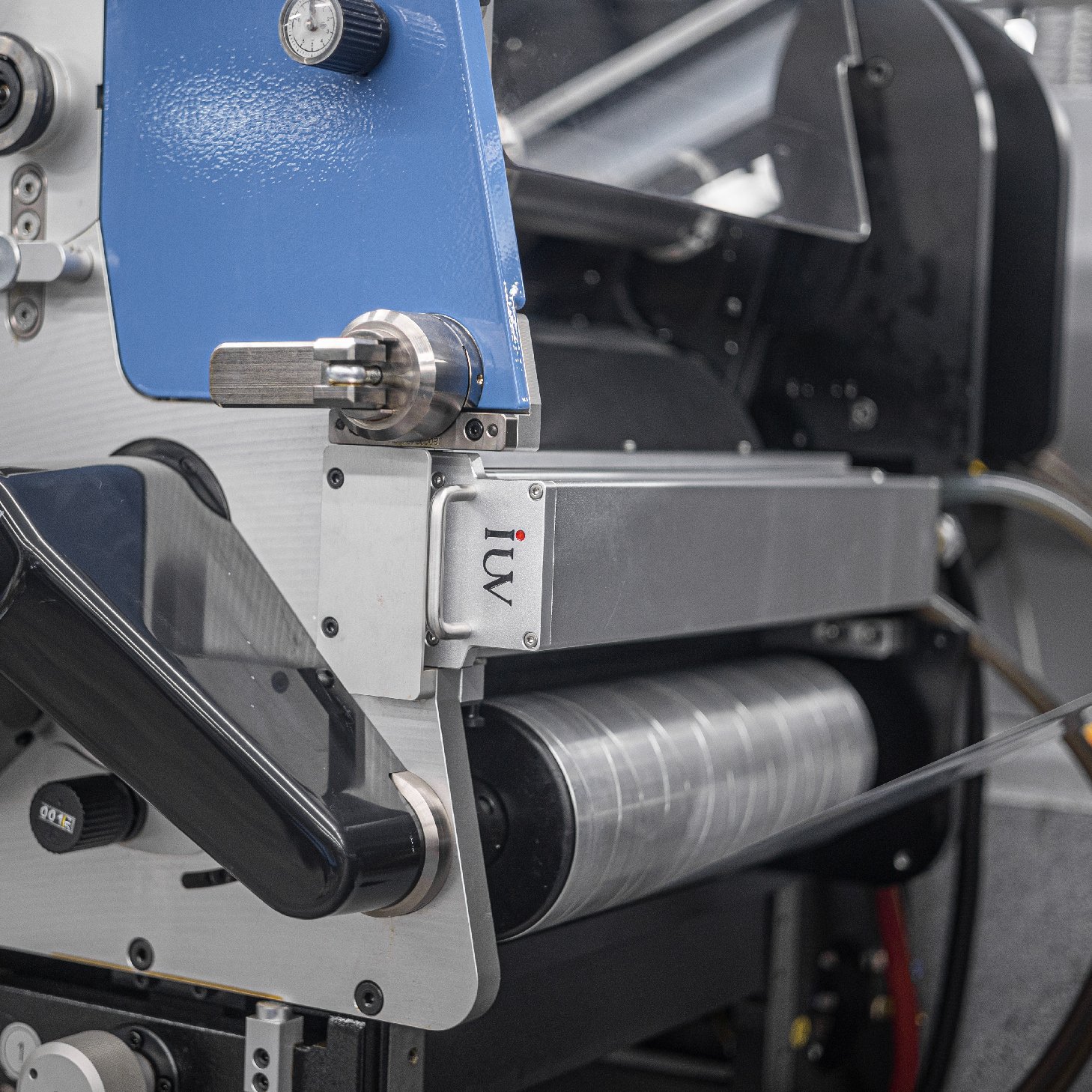

Enter LED UV Curing: A Game Changer

The advent of UV (ultraviolet) curing technology, and more specifically LED UV curing, has been a pivotal development. Traditional UV curing systems often used mercury vapor lamps, which generated significant heat and had a limited lifespan. LED UV curing, on the other hand, utilizes light-emitting diodes to produce UV light. This offers several distinct advantages:

- Lower Heat Emission: LEDs produce a much narrower spectrum of UV light and generate far less heat. This is crucial for printing on heat-sensitive substrates like thin films and certain plastics, expanding the range of materials that can be used for labels.

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs are instantly on or off. This reduces energy consumption and allows for more precise control, which is vital in high-speed operations.

- Longer Lifespan: LED UV lamps have a significantly longer operational life than mercury lamps, leading to reduced maintenance and replacement costs.

- Energy Efficiency: LEDs are considerably more energy-efficient, translating into lower operational expenses.

- Compact Footprint: LED UV systems are often more compact, allowing for easier integration into existing or new printing presses, especially in narrow-web applications.

Automated UV Printing for High-Speed Digital Labels

When we talk about “Automated UV Printing Operations for High-Speed Digital Label Manufacturing,” we are referring to a sophisticated system where digital printing technology is seamlessly integrated with advanced LED UV curing, all managed by automation.

In a high-speed digital label press equipped with automated UV printing, the process typically involves:

- Digital Data Input: Print jobs are received digitally, often including variable data such as serial numbers, barcodes, or different designs for each label. Automation ensures that this data is processed accurately and efficiently.

- Digital Printing Engine: The digital print heads apply ink directly to the substrate. Depending on the press, this could be inkjet technology (like DOD – Drop-on-Demand) or other digital imaging processes.

- Immediate UV Curing: As the ink is applied, it passes immediately under LED UV lamps. The UV light initiates a photochemical reaction, instantly curing (drying or solidifying) the ink. This rapid curing is what allows for very high printing speeds.

- Substrate Versatility: Because LED UV curing produces minimal heat, these systems can print on a wide array of substrates, including paper, various plastics (BOPP, PET, PE), and even some metallic foils. This flexibility is a significant advantage in the diverse label market.

- Automation Integration: The “automated” aspect is key. This means that the entire workflow, from job setup and ink management to print head maintenance and curing lamp operation, is controlled by a sophisticated software system. Automation minimizes manual intervention, reduces the potential for human error, and ensures consistent quality across long production runs. This includes automated registration control, color management, and waste reduction.

Impact on Different Printing Modalities

While the focus is on digital, the principles of UV curing are also integral to modern flexographic and offset printing, especially in narrow-web label production.

Narrow-Web Flexographic and Offset Presses: These traditional methods have also seen significant upgrades with UV and LED UV curing. In these scenarios, UV-curable inks are used. As the substrate moves through the press, it passes under UV lamps after each color station. This allows for:

- Faster Speeds: The ink dries instantly, so the press doesn’t need to accommodate slow drying times. This enables higher press speeds and therefore higher output.

- Vibrant Colors and High Contrast: UV inks often provide brighter, more opaque colors, which are excellent for label applications where visual appeal is paramount.

- Durability: Cured UV inks are typically more resistant to scuffing, chemicals, and fading than conventional inks.

- Substrate Compatibility: Similar to digital, UV curing allows these presses to handle a wider range of non-porous substrates.

- Reduced VOCs: UV inks are solvent-free, meaning they don’t release Volatile Organic Compounds (VOCs) into the environment during the curing process. This is a significant environmental benefit.

The automation in these presses focuses on makeready reduction, ink density control, and color consistency, all enhanced by the rapid curing enabled by UV technology.

Benefits of Automated UV Printing in Digital Label Manufacturing

The synergy between automated digital printing and LED UV curing delivers a powerful set of advantages:

- Unprecedented Speed: Digital presses can now achieve speeds that rival or even surpass traditional methods for certain job types, especially when coupled with efficient UV curing. This drastically reduces lead times for label orders.

- Enhanced Substrate Range: The low heat and precise curing of LED UV open doors to printing on an extensive variety of films and papers previously challenging for digital. This broadens design possibilities and material choices.

- Superior Print Quality: Modern UV inks, combined with high-resolution digital print heads and precise curing, produce exceptionally sharp, vibrant, and durable labels. This includes excellent color gamut and fine detail.

- Cost-Effectiveness for Varied Runs: Automation minimizes setup times inherent in digital printing. Coupled with the speed and substrate flexibility of UV curing, this makes even short and medium runs highly economical, while also handling larger runs efficiently.

- Reduced Waste: Precise automated controls for color, registration, and ink application, along with the instant curing, significantly reduce the amount of waste material generated during setup and production.

- Environmental Advantages: As mentioned, UV inks are typically VOC-free, and LED UV systems are more energy-efficient than older technologies. Automation further contributes by optimizing material usage.

- Consistency and Repeatability: Automation ensures that every label produced, whether it’s the first or the ten-thousandth, meets the same high standards for color, registration, and cure quality.

- Expanded Application Possibilities: The combination of speed, quality, and substrate flexibility allows for labels in more demanding applications, from food and beverage packaging that requires chemical resistance to outdoor durable labels.

The Future of Label Manufacturing

Automated UV printing operations are not just an incremental improvement; they represent a fundamental shift in how labels are manufactured. The ability to achieve high speeds, print on diverse materials, maintain exceptional quality, and operate with significant cost and environmental efficiencies makes this technology a cornerstone for the future of the label industry. As digital printing technology continues to advance, and LED UV curing becomes even more refined, we can expect even greater integration and performance from these automated systems. This evolution promises a more agile, responsive, and sustainable label manufacturing landscape.