The demand for labels is constantly growing, driven by everything from consumer goods to pharmaceuticals. For manufacturers, scaling production while maintaining quality and cost-effectiveness is a significant challenge. This is where automated UV printing operations emerge as a powerful solution, offering a pathway to efficient and profitable label manufacturing.

The Bottlenecks in Traditional Label Printing

Historically, label printing has relied on various methods, each with its own set of limitations when it comes to scalability. Flexographic (flexo) printing, while versatile for long runs and a wide range of substrates, can involve extensive setup times and ink changes. Offset printing offers high quality but is typically best suited for very large volumes and can be less adaptable to the shorter, more frequent runs that are common in today’s market.

Narrow web printing, the mainstay of the label industry, has seen continuous innovation. However, traditional drying methods, such as hot air or IR (infrared), often create bottlenecks. These methods require significant drying tunnels, which take up valuable floor space and can slow down the press speed. Furthermore, the energy consumption of these systems can be substantial, impacting operational costs. The slower drying times also mean that labels may need to sit longer before finishing processes like die-cutting or rewinding can occur, adding further delays to the production cycle.

Introducing LED UV Curing: A Game Changer

The advent of UV curable inks and, more specifically, LED UV curing technology has revolutionized printing processes. Unlike traditional UV lamps that generate heat and ozone, LED UV systems emit light within a narrow wavelength range, efficiently curing the ink. This focused energy transfer offers several advantages that directly address the scalability issues faced by label manufacturers.

The Power of Automation in UV Printing

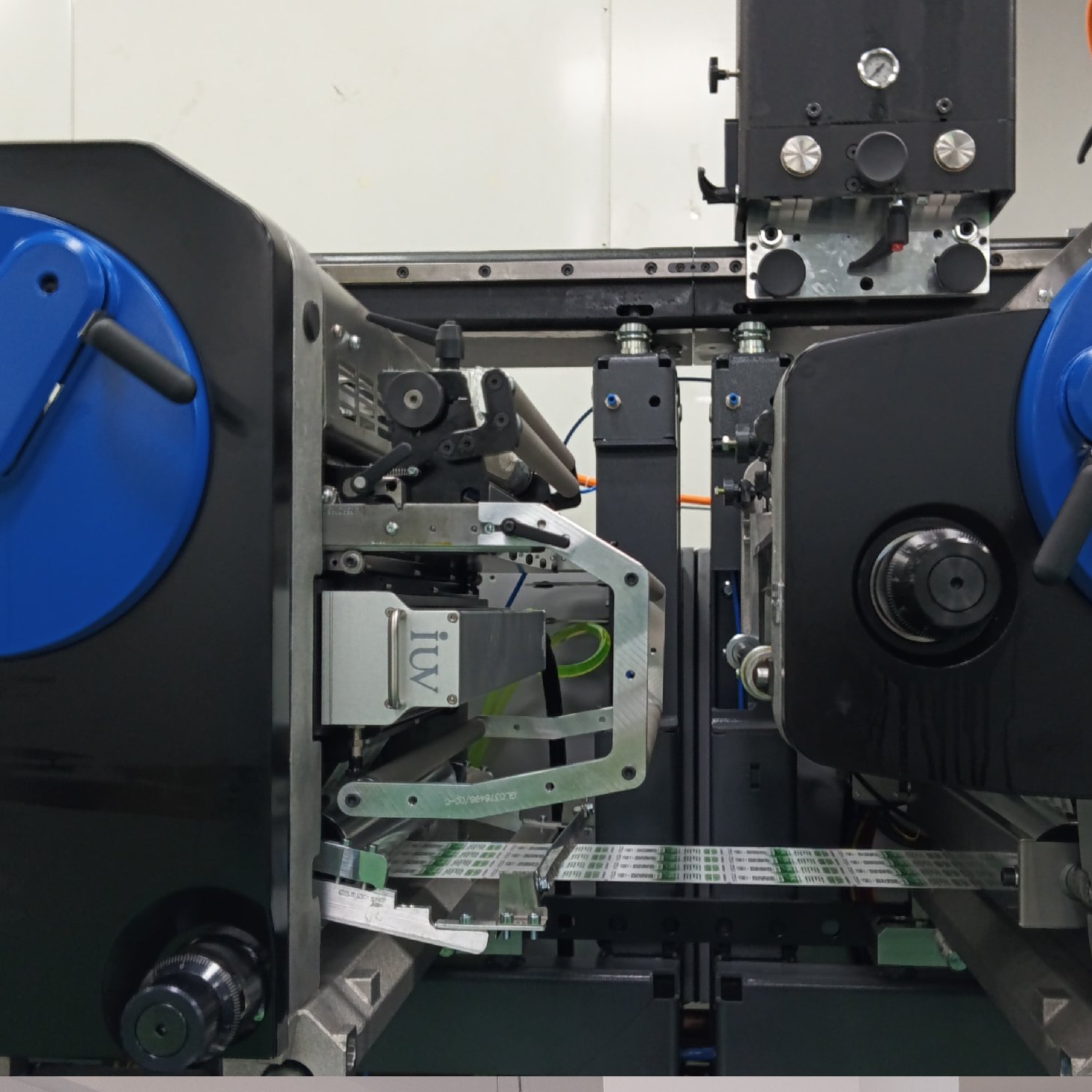

Combining LED UV curing with automated operations creates a synergy that unlocks true scalability. Automation in this context refers to the integration of various printing and finishing steps into a seamless workflow, often with minimal human intervention.

Faster Speeds, Higher Throughput

LED UV curing allows inks to dry almost instantaneously upon exposure to the UV light. This means presses can run at significantly higher speeds because there’s no need to wait for inks to evaporate or absorb into the substrate. Automated systems are designed to take advantage of these speeds, continuously feeding substrate, printing, curing, and delivering finished labels without significant pauses. This dramatically increases the number of labels that can be produced in a given timeframe.

Reduced Downtime and Setup

Automated UV printing systems often feature quick changeover capabilities for anilox rolls, plates, and ink systems. Coupled with the instant curing of UV inks, this drastically reduces setup and downtime between jobs. Operators can move from one job to the next much faster, maximizing press utilization. This is particularly beneficial for label printers handling a diverse range of orders with varying specifications and quantities.

Superior Print Quality and Consistency

LED UV inks, when properly cured, offer excellent adhesion, rub resistance, and vibrant color reproduction. Automated systems ensure precise control over ink laydown, registration, and UV energy exposure. This consistency is maintained throughout the entire print run, eliminating the variations that can occur with manual adjustments. The result is a higher quality product, batch after batch, which is crucial for brand owners and end-users.

Versatility Across Substrates

A significant advantage of UV curing, especially with LED technology, is its ability to print on a wide array of substrates, including non-porous materials like films and foils, as well as traditional paper stocks. This versatility allows manufacturers to cater to a broader market and offer a wider range of label solutions. Automated systems, integrated with LED UV curing, can handle these diverse materials efficiently without compromising drying quality.

Environmental and Operational Benefits

LED UV curing systems are more energy-efficient than traditional mercury vapor UV lamps. They also produce less heat and no ozone, contributing to a safer and more comfortable working environment. Furthermore, UV curable inks typically contain a higher percentage of solids and fewer volatile organic compounds (VOCs) compared to solvent-based inks, making them a more environmentally friendly choice. The reduced heat output from LEDs also means less strain on the substrate, preventing distortion, particularly with sensitive filmic materials.

Implementing Automated UV Printing for Scalability

To successfully leverage automated UV printing for scalable label manufacturing, consider the following aspects:

- Press Selection: Choose a narrow web press that is specifically designed for or can be retrofitted with LED UV curing units at each print station and for the finishing section. Look for automation features such as automated plate loading, automated registration control, and in-line inspection systems.

- Ink Management: Invest in a robust ink management system that supports automated ink dispensing and delivery to the print stations. This minimizes manual handling and ensures consistent ink viscosity and color.

- Curing Integration: Ensure the LED UV curing units are properly matched to the press speed and ink formulation. Proper placement of curing units between print stations and at the end of the line is critical for achieving optimal cure and performance.

- Finishing Integration: Integrate in-line finishing capabilities such as die-cutting, slitting, and slitting/rewinding. Automated systems that can handle these processes directly after printing and curing eliminate the need for offline handling, further streamlining production.

- Workflow and MIS: Implement a robust Management Information System (MIS) that can manage job scheduling, material tracking, production reporting, and cost analysis. This system should integrate seamlessly with the automated press controls to provide real-time data and facilitate efficient planning.

- Operator Training: While automation reduces manual intervention, skilled operators are still essential. Proper training on operating and maintaining automated UV printing equipment, as well as troubleshooting, is crucial for maximizing efficiency and ensuring consistent quality.

The Future is Automated and UV-Cured

As the label market continues to evolve, with demands for shorter lead times, greater customization, and cost efficiency, automated UV printing operations present a clear path forward for manufacturers seeking to scale their production. By embracing the speed, quality, and versatility offered by LED UV technology, coupled with intelligent automation, businesses can overcome traditional bottlenecks and position themselves for sustained growth and success in the competitive label manufacturing landscape. The investment in these technologies is not just about keeping up; it’s about leading the way in efficient, high-quality label production.