Achieving Superior Print Quality with UV Curing Systems in Flexo Printing

In the dynamic world of label printing, achieving exceptional quality is paramount. Flexographic printing, often referred to as flexo, has long been a workhorse for producing high volumes of labels efficiently. When combined with advanced UV curing systems, flexo printing unlocks new levels of brilliance, durability, and versatility. This is especially true for narrow web printing applications where precision and speed are critical.

The magic of UV curing lies in its ability to instantly harden inks and coatings upon exposure to ultraviolet light. Unlike traditional heat-set or air-drying methods, UV curing offers significant advantages. For flexo printing, this means sharper dot definition, more vibrant colors, and the ability to print on a wider array of substrates, including non-porous materials like films and foils.

LED UV curing technology represents the latest evolution in this field. Traditional mercury lamp UV systems generate significant heat and consume more energy. LED UV lamps, on the other hand, are more energy-efficient, generate less heat, and have a much longer lifespan. This translates to lower operating costs and a more sustainable printing process. For narrow web printers, especially those focused on label production, this efficiency is a game-changer.

The impact on print quality is immediate. UV inks, when cured instantly, create a dense, robust ink film. This results in exceptional color saturation and contrast, making your labels pop off the shelf. In flexo printing, where anilox rolls and photopolymer plates are key to transferring ink, the precise curing of UV inks ensures that the fine details and gradients are reproduced faithfully. This level of detail is crucial for intricate designs and high-resolution graphics commonly found on labels.

Furthermore, UV inks offer superior scratch and chemical resistance. This is vital for labels that will be exposed to harsh environments, frequent handling, or demanding applications. Think of product labels on cleaning supplies, automotive parts, or outdoor equipment. The durability provided by UV curing ensures that the printed message remains clear and intact, maintaining brand integrity throughout the product’s lifecycle.

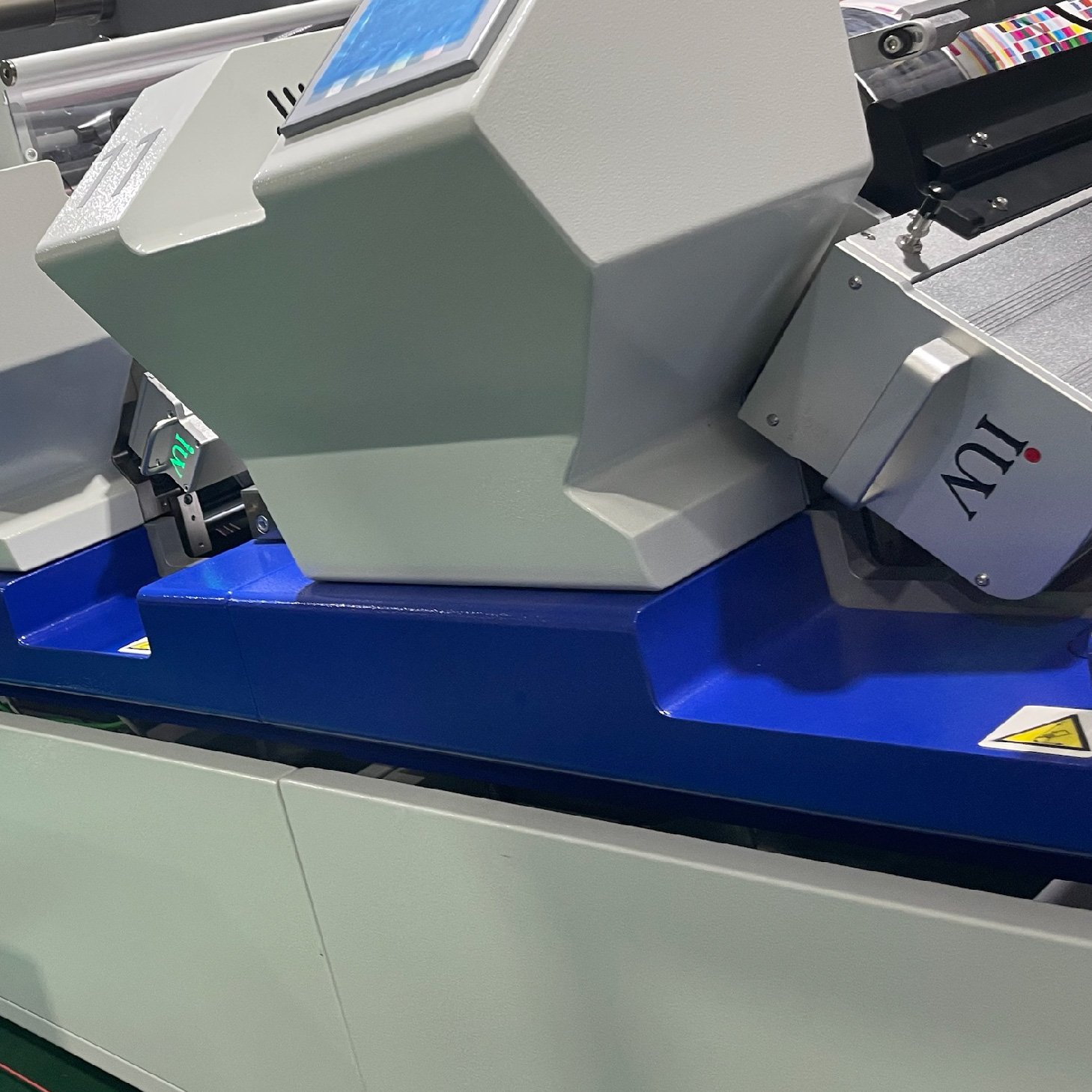

The integration of UV curing systems into flexo presses has revolutionized narrow web printing. Presses are now designed with dedicated UV curing stations positioned between printing units. This allows for multiple ink colors to be printed and cured sequentially, achieving complex multi-color designs with remarkable consistency. The speed at which UV inks cure means printers can run their presses at higher speeds without compromising on quality, a significant benefit for high-volume label production.

The versatility of UV inks extends to their application on various substrates. While offset printing often requires porous paper stock, flexo with UV curing excels on films, foils, and even some plastics. This opens up a world of packaging and labeling possibilities. For example, printing on clear films for window decals or on metallic foils for premium cosmetic labels becomes much more achievable with UV technology. The ability to achieve superior adhesion on these challenging surfaces is a direct result of the instantaneous curing process.

When discussing flexo printing, it’s important to consider the interplay between ink, plates, and the anilox roll. UV inks have specific rheological properties that are optimized for flexo transfer. The rapid curing ensures that the ink doesn’t spread or mottle during the drying process, preserving the integrity of the image laid down by the anilox roll and plate. This precise control over ink behavior is what leads to the sharp, clean print that defines high-quality labels.

For label printers, embracing UV curing is not just about improving current output; it’s about future-proofing their operations. The market demands faster turnaround times, higher quality, and more sustainable practices. LED UV curing systems directly address these demands. Their lower energy consumption contributes to a smaller carbon footprint, and their longer lifespan reduces waste associated with lamp replacement. This aligns with the growing trend towards environmentally conscious manufacturing.

The learning curve for adopting UV curing in flexo printing is manageable. Many press manufacturers offer integrated UV systems, simplifying the installation and operation process. Training for press operators typically involves understanding the specific parameters for different UV inks and lamps, such as exposure time and intensity, to achieve optimal cure. Once these parameters are understood, the benefits in terms of print quality and operational efficiency are substantial.

In conclusion, for narrow web flexo printers aiming for superior print quality in label production, the adoption of UV curing systems, particularly LED UV technology, is a strategic imperative. It delivers vibrant colors, exceptional durability, and the flexibility to print on a wide range of materials. The efficiency and sustainability offered by modern UV systems further enhance their value proposition, making them an indispensable tool for competitive label printers. The continuous innovation in UV ink formulations and curing hardware ensures that flexo printing will remain a dominant force in label production for years to come, powered by the brilliance of UV light.