Achieving superior adhesion with UV ink performance optimization in flexo printing is a constant pursuit for label printers. The demands of modern packaging require inks that not only deliver vibrant color and sharp detail but also form a robust bond with a diverse range of substrates. This is where a deep understanding of UV ink chemistry and the intricacies of flexographic printing processes becomes invaluable. Optimizing UV ink performance isn’t just about selecting the right ink; it’s a multi-faceted approach that considers curing technology, substrate interaction, and print application specifics.

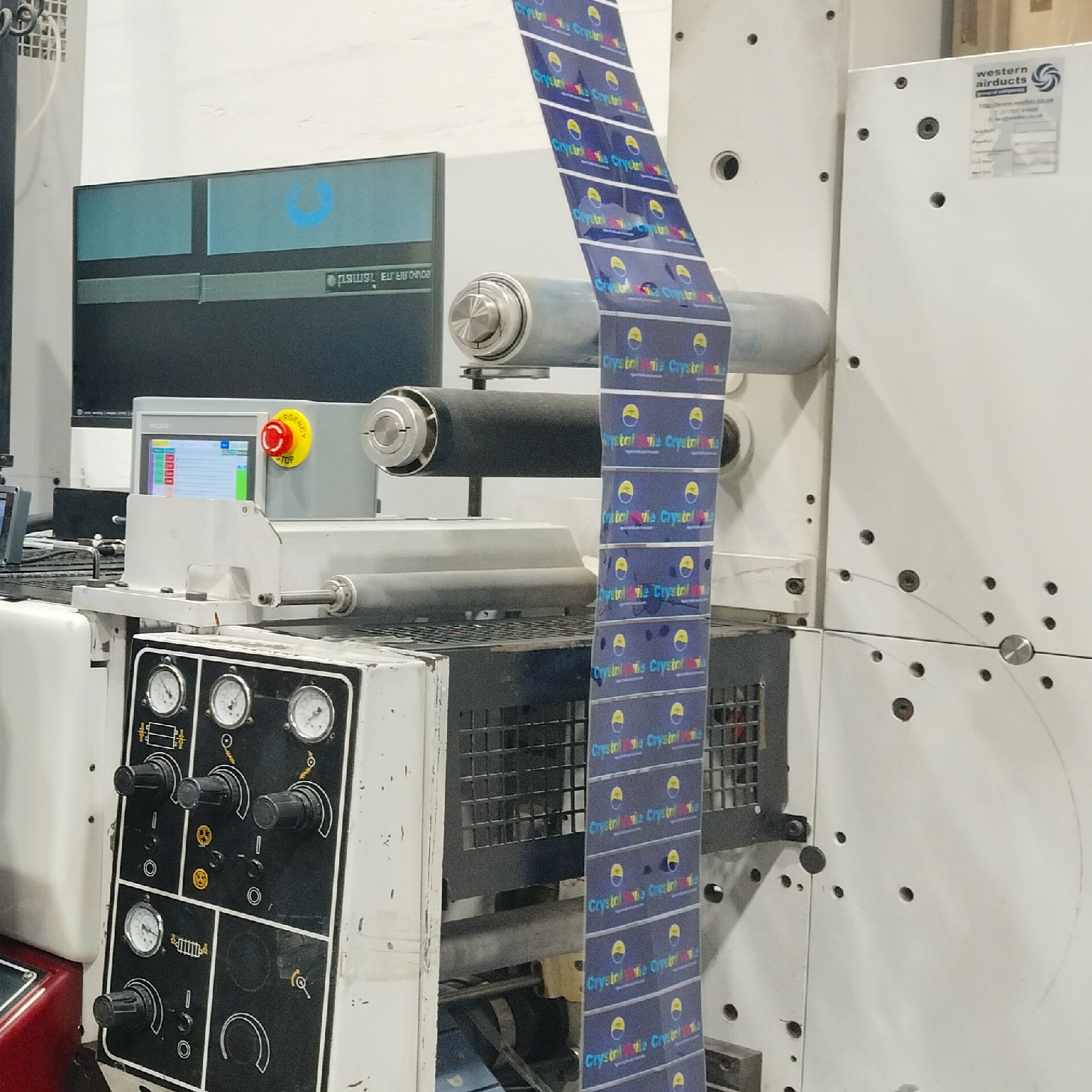

In the realm of narrow web printing, where flexography reigns supreme for label production, the stakes for adhesion are particularly high. Labels are often subjected to stresses during application, handling, and their intended use, whether that’s a food container enduring refrigeration or a chemical bottle exposed to varied environments. Failure to achieve optimal adhesion can lead to delamination, ink rub-off, and ultimately, brand integrity compromised. This makes the careful calibration of UV ink performance a critical factor for success.

Understanding UV Ink Chemistry for Flexography

UV-curable inks are formulated with monomers, oligomers, photoinitiators, and pigments. Upon exposure to UV light, the photoinitiators absorb energy and initiate a rapid polymerization process. This cross-linking reaction transforms the liquid ink into a solid, durable film. The specific choice of monomers and oligomers significantly influences the ink’s adhesion properties. For instance, inks with higher functional groups tend to form stronger bonds. Similarly, the interaction between the ink’s chemical structure and the substrate’s surface energy is paramount.

Substrates commonly used in narrow web flexo printing, such as various films (polypropylene, polyethylene, polyester) and papers, possess different surface characteristics. Some are inherently receptive to ink adhesion, while others, particularly low-surface-energy plastics, require surface treatment like corona or plasma to enhance wettability and adhesion. The UV ink formulation must be compatible with the substrate, or surface treatment, to achieve a lasting bond.

The Role of LED UV Curing Technology

The evolution of UV curing technology from mercury lamps to UV-LED systems has brought about significant advancements in ink performance and adhesion. UV-LED curing offers a more controlled and efficient way to initiate the polymerization process. Unlike mercury lamps that emit a broad spectrum of light, UV-LEDs emit specific wavelengths tailored to the absorption spectrum of the photoinitiators. This targeted energy delivery can lead to more complete and uniform curing.

Proper curing is directly linked to adhesion. If the ink is under-cured, the polymerization is incomplete, resulting in a weaker film with compromised mechanical properties, including adhesion. Over-curing, while less common with LED, can sometimes lead to brittleness, which might also affect adhesion under certain flexural stresses. UV-LEDs allow for precise control over the energy delivered (dose) and the intensity of the UV light (irradiance). Optimizing these parameters ensures that the photoinitiators are activated effectively, leading to thorough curing and superior adhesion.

Optimizing Ink-Substrate Interaction

The initial step in achieving superior adhesion is understanding the substrate. A thorough surface energy measurement of the substrate can inform ink selection and the necessity of surface treatment. For low-surface-energy plastics, a corona treatment is often employed to increase the surface energy, making it more receptive to ink. The effectiveness of this treatment must be maintained and verified.

When selecting UV inks for flexographic printing, it is crucial to communicate with ink manufacturers about the intended substrates. Reputable ink suppliers will offer formulations specifically designed for adhesion to challenging materials. They can advise on ink systems that incorporate adhesion promoters or are designed for specific surface chemistries.

Key Factors for Adhesion in Flexo Printing

Several critical factors influence adhesion in UV flexographic printing:

- Ink Rheology: The viscosity and flow properties of the UV ink are essential for proper ink transfer from the anilox roll to the printing plate and then to the substrate. Correct rheology ensures a consistent ink film thickness, which is vital for uniform curing and adhesion.

- Ink Film Thickness: Too thin a film may not provide sufficient material for cross-linking, while too thick a film can lead to incomplete through-cure, especially in areas with dense ink coverage. Consistent and appropriate film thickness is achieved through careful selection of the anilox roll’s cell volume and engraving pattern, along with press speed and ink viscosity.

- Substrate Surface Condition: As mentioned, the surface energy of the substrate is paramount. Dust, oils, or mold release agents on the substrate surface can act as barriers to adhesion. Maintaining a clean and properly treated substrate is non-negotiable.

- UV Curing Parameters: This is arguably the most critical element for UV ink adhesion. The wavelength of the UV light, the intensity (irradiance), and the total energy delivered (dose) must be precisely matched to the ink’s photoinitiator package.

- Wavelength: Ensuring the UV-LED emitters produce wavelengths that the photoinitiators can efficiently absorb is fundamental. Mismatched wavelengths will result in poor cure.

- Irradiance: This refers to the power density of the UV light. Higher irradiance means more photons are available to initiate polymerization per unit time, leading to faster curing. However, excessive irradiance can sometimes cause surface cure while leaving the lower layers under-cured.

- Dose: This is the total amount of UV energy delivered to the ink film (irradiance x exposure time). A sufficient dose is required to achieve complete cross-linking throughout the ink film. This is often expressed in Joules per square centimeter (J/cm²).

- Dwell Time (Exposure Time): The amount of time the ink film is exposed to the UV light source. This is directly related to press speed and the number of UV units. Longer dwell times at a given irradiance increase the total dose.

- Environmental Factors: Temperature and humidity can indirectly affect adhesion by influencing substrate properties or ink viscosity.

Troubleshooting Adhesion Issues in Flexo Printing

When adhesion problems arise, a systematic troubleshooting approach is necessary.

- Visual Inspection: Check for any signs of delamination, peeling, or poor ink laydown.

- Adhesion Testing: Employ standard adhesion tests such as the tape test (e.g., using 3M 610 or 600 tape) or cross-hatch adhesion tests. These tests provide a quantitative measure of adhesion.

- Review Curing Parameters: Verify that the UV-LED system is functioning correctly. Check power output and ensure the correct curing program is selected for the specific ink. Measure the UV irradiance at the substrate level to confirm the delivered energy.

- Substrate Check: Confirm the substrate’s surface energy and the effectiveness of any pre-treatment. Ensure the substrate is clean and free from contaminants.

- Ink Assessment: Evaluate the ink’s viscosity and its compatibility with the substrate. Consult the ink manufacturer for recommended application parameters and any potential batch variations.

- Press Settings: Examine anilox roll selection, impression settings, and doctor blade condition, as these impact ink transfer and film thickness.

The Future of UV Ink Adhesion in Flexography

The drive for sustainability and improved performance continues to shape UV ink technology for flexographic printing. Innovations in ink chemistry are leading to formulations that offer enhanced adhesion to a wider range of substrates, including recycled and compostable materials, often with reduced or no need for aggressive surface treatments. Furthermore, the development of more energy-efficient UV-LED curing systems and inks that cure at lower energy levels will reduce operational costs and environmental impact.

By meticulously controlling each element – from ink formulation and substrate preparation to the precise calibration of UV-LED curing parameters – printers can consistently achieve superior adhesion. This not only ensures the quality and durability of the printed product but also safeguards brand reputation and customer satisfaction in the competitive narrow web label market. Mastering UV ink performance optimization is a continuous journey of understanding, precise execution, and adaptation to new technologies.