Efficiency in modern pressrooms often hinges on the ability to manage diverse technologies simultaneously. As the industry shifts from traditional mercury arc lamps to LED systems, many narrow-web and label converters find themselves running mixed ink sets. This hybrid environment presents unique challenges for curing consistency. Achieving a total cure across different ink chemistries requires a deep understanding of light energy, photoinitiator response, and mechanical precision.

The Physics of the Hybrid Pressroom

Traditional UV curing relies on mercury vapor lamps. These lamps emit a broad spectrum of light, ranging from UVC to visible light. This wide output allows them to trigger a variety of photoinitiators throughout the ink film. In contrast, LED curing systems are monochromatic. They typically peak at 385nm or 395nm.

When you run a mixed ink set, you are dealing with two different absorption profiles. LED-optimized inks contain photoinitiators specifically tuned to high-intensity, long-wavelength UV light. Standard UV inks may require the shorter wavelengths (UVC and UVB) provided by mercury lamps to achieve surface hardness. Optimization starts with acknowledging that a “one size fits all” approach to lamp power will lead to failure.

Matching Wavelengths to Ink Chemistry

The primary goal in any curing process is to ensure the spectral output of the lamp matches the absorption characteristics of the ink. In a mixed environment, this becomes a balancing act. If you use an LED-curable ink under a mercury lamp, the ink will likely cure, but you may waste significant energy.

However, the reverse is rarely true. Standard UV inks often fail to cure under LED lamps because they lack the specific photoinitiators needed for the 395nm range. When setting up your narrow-web press, verify the compatibility of every ink station. If you are running a four-color process set optimized for LED alongside a specialty metallic or fluorescent ink designed for mercury, your lamp configuration must reflect that.

Optimizing Ink Film Thickness in Flexo and Offset

Ink film thickness directly impacts curing speed and quality. In flexographic printing, the anilox roll volume determines the amount of ink delivered to the substrate. Thicker films require more energy to achieve a full through-cure. If the ink is too thick, the UV light may be absorbed by the top layer, leaving the bottom of the ink film liquid. This results in poor adhesion and potential ink migration.

For narrow-web offset printing, the ink keys and dampening system play a similar role. Offset inks are generally more pigmented and applied in thinner layers than flexo inks. While this makes them easier to cure in some respects, the high pigment density can block UV light. When working with mixed sets, adjust your anilox selection or ink key settings to find the lowest possible film weight that still meets your color targets.

The Role of Irradiance vs. Energy Density

Understanding the difference between irradiance and energy density is vital for process control. Irradiance (measured in W/cm²) is the peak intensity of the light hitting the surface. Think of this as how “bright” the light is. Energy density (measured in J/cm²) is the total amount of light energy delivered over time. This depends on the press speed.

LED systems provide very high irradiance but within a narrow band. Mercury lamps provide lower peak irradiance but cover a broader spectrum. To optimize a mixed set, use a radiometer to profile each station. Ensure your LED lamps are delivering enough peak intensity to penetrate thick white bases or dark blacks. Simultaneously, monitor the “dose” from your mercury lamps to ensure the surface of the ink is not becoming brittle from over-exposure.

Managing Heat in Label Printing

One of the biggest advantages of LED curing is the reduction of heat transferred to the substrate. Thin films and heat-sensitive label stocks can distort under the intense infrared radiation emitted by mercury lamps. In a mixed setup, the heat management strategy must be robust.

If your press uses mercury lamps for certain stations, ensure your chill rollers are functioning at peak efficiency. Excessive heat can change the viscosity of the inks in the remaining stations, leading to color drift. LED stations run much cooler, but the power supplies still generate heat. Proper ducting and cooling for the LED heads prevent thermal expansion of the press components, which maintains registration accuracy.

Focal Point and Lamp Geometry

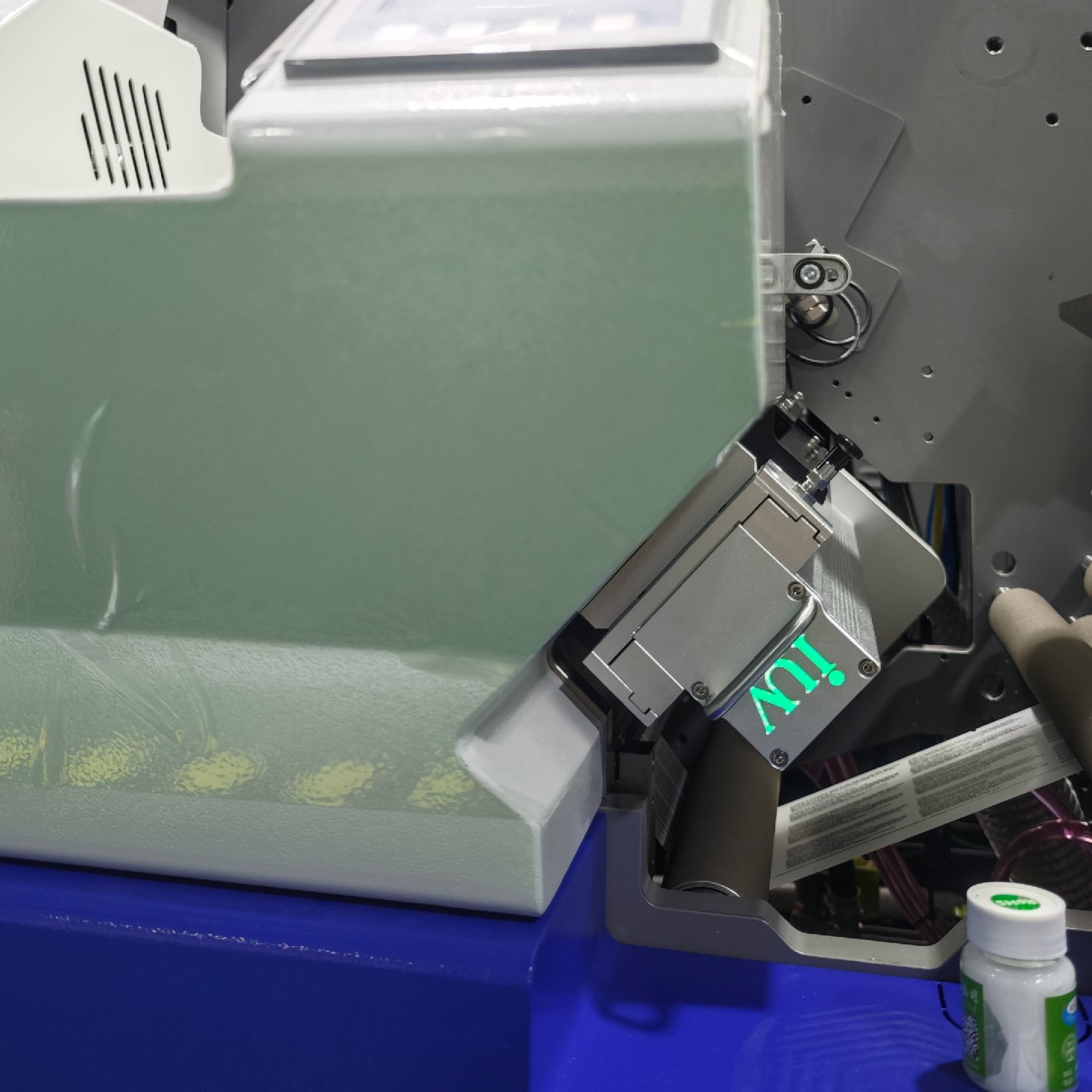

The physical position of your curing units determines how much light actually reaches the ink. Mercury lamps use reflectors to focus light into a narrow line. If the lamp is out of focus, the irradiance drops significantly. Check your reflectors for signs of oxidation or warping. Even a small layer of dust can reduce output by 20%.

LED arrays do not use traditional reflectors in the same way, but their distance from the web is even more critical. LED light diverges quickly. Moving an LED bar just a few millimeters away from the substrate can result in a massive loss of curing power. In narrow-web applications, keep the LED heads as close to the web as the press mechanics allow. This ensures maximum photon density reaches the ink film.

Testing and Validation Procedures

You cannot optimize what you do not measure. Relying on a “thumb twist” test is insufficient for professional label and packaging production. Implement a standardized testing protocol for every job involving mixed ink sets.

- Cross-Hatch Adhesion Test: Use standardized tape to check the bond between the ink and the substrate. This is the most basic indicator of through-cure.

- MEK Rub Test: This chemical resistance test determines the degree of polymerization. If the ink dissolves quickly, the cross-linking is incomplete.

- Granular Radiometry: Use a calibrated radiometer to record the W/cm² and J/cm² for every station. Log these values against the press speed.

- Extraction Testing: For food packaging, lab-based extraction tests ensure that no unreacted monomers remain in the ink film.

Adjusting Press Speed for Mixed Workflows

In a perfect world, your press runs at its mechanical limit. In a mixed ink environment, the “slowest” ink or lamp dictates the maximum speed. If your mercury lamps are reaching the end of their lifespan, they will require slower speeds to achieve the necessary energy density.

Modern LED systems often allow for much higher speeds than older mercury units. However, if you are running a hybrid setup, you must synchronize the curing window. If the LED-curable cyan cures at 500 fpm, but the mercury-curable spot color only reaches full polymerization at 300 fpm, you must run at 300 fpm. Regularly check lamp hours to prevent unexpected bottlenecks.

Maintenance of Mixed Curing Systems

Maintenance requirements differ between the two technologies. Mercury lamps require frequent bulb changes (typically every 1,000 to 1,500 hours) and constant cleaning of the reflectors. Failure to maintain reflectors leads to “soft” cures and surface tackiness.

LED systems are rated for 20,000 hours or more, but they are not maintenance-free. The protective glass or lenses must be kept spotless. Any ink mist or dust on the LED window will bake on, creating a permanent shadow that prevents curing in that zone. In flexo printing, ink mist is common. Establish a daily cleaning routine using approved solvents to protect your LED investment.

Strategic Transitioning

Optimizing mixed ink sets is often a bridge to a full LED conversion. During this transition, work closely with your ink supplier. Many ink manufacturers now offer “universal” inks that react well to both mercury and LED light. These formulations can simplify your inventory and reduce the risk of operator error.

By focusing on the physics of light, the chemistry of the photoinitiators, and the mechanical precision of the press, you can achieve high-quality results in a hybrid environment. Consistent measurement and proactive maintenance are the keys to avoiding downtime and ensuring customer satisfaction in the competitive label and narrow-web markets.