The demand for sensory packaging has reached an all-time high. Brands no longer rely solely on visual appeal to capture consumer attention. They now demand tactile experiences—textures that mimic linen, wood grain, or high-build braille-like effects. Traditionally, achieving these results required secondary finishing processes or power-hungry mercury vapor lamps.

The industry has shifted. LED UV curing technology now allows printers to produce high-end inline embossing and tactile effects directly on the press. This guide explores the technical integration of LED UV within narrow-web, flexographic, and offset printing environments.

The Shift to LED UV in Specialty Finishing

Standard UV curing relied on mercury lamps for decades. While effective, these lamps generate immense heat and emit a broad spectrum of light. For tactile effects, where the varnish layer is significantly thicker than standard ink, heat is an enemy. Excessive heat distorts thin films and heat-sensitive substrates commonly used in label printing.

LED UV systems emit light at specific wavelengths, typically 385nm or 395nm. This monochromatic output is far more efficient for deep-layer polymerization. In tactile applications, the light must penetrate a thick “dome” of varnish to reach the substrate interface. LED UV provides the intensity required to ensure a full cure from the top surface down to the base.

Achieving High-Build Tactile Effects Inline

Tactile effects, often called “3D varnish” or “digital embossing,” involve applying a high-viscosity UV resin. In a narrow-web flexo environment, this is usually achieved through a rotary screen unit or a specialized heavy-volume anilox roll.

Integration with Flexography and Narrow Web

In flexo printing, the challenge is maintaining the structural integrity of the varnish before it hits the curing station. If the varnish flows too much, the sharp edges of the embossing are lost.

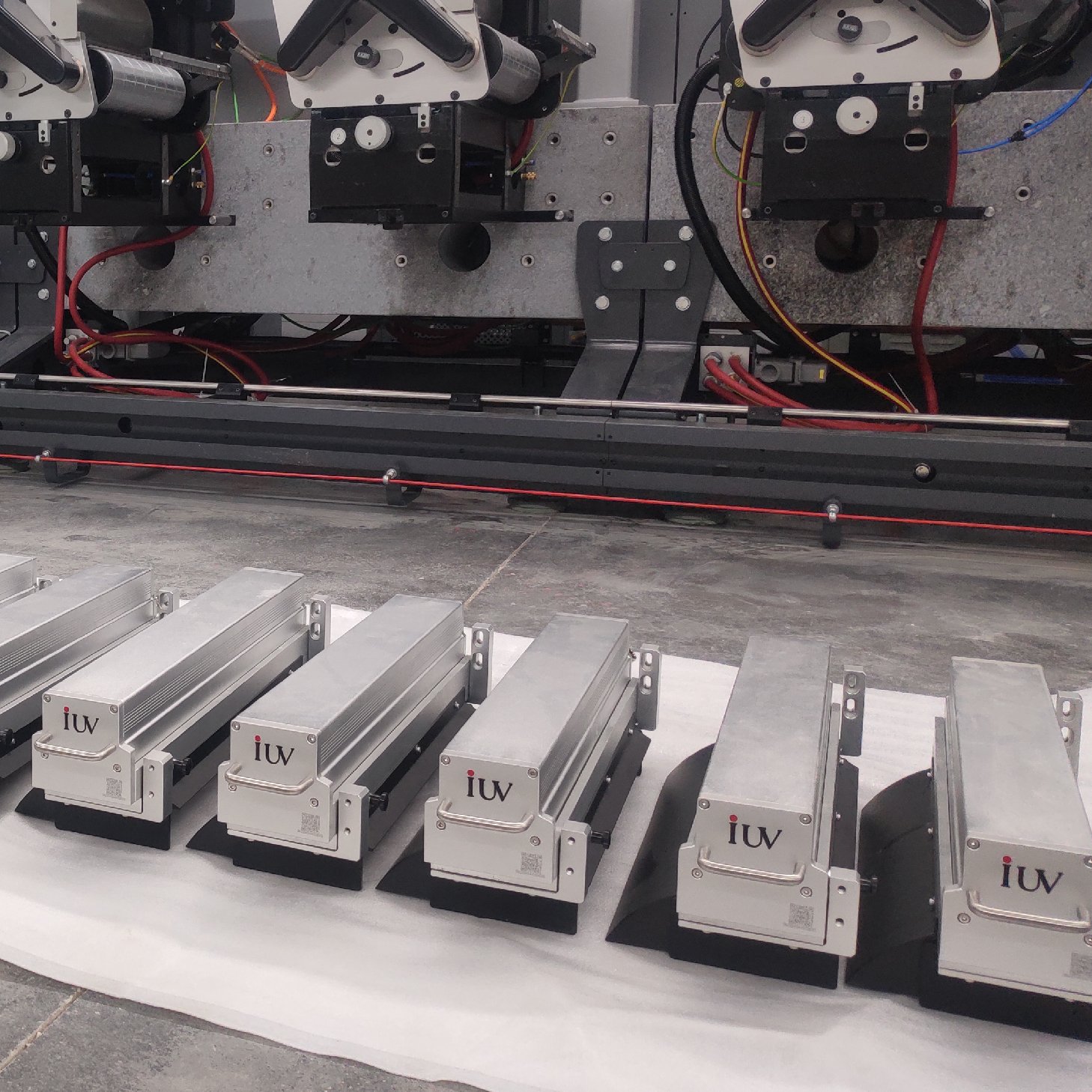

LED UV units are compact. They can be placed immediately after the application station. This “pinning” or full curing happens instantly. Because LED lamps reach full power immediately without warm-up times, the press can maintain high speeds without compromising the height of the tactile effect.

The Role of Offset Printing

Sheet-fed offset printers are also adopting LED UV for tactile finishes. In this setup, a coating unit applies the UV-curable varnish over the printed CMYK layers. LED curing prevents the “orange peel” effect often seen when traditional coatings are cured too slowly. The instant polymerization locks the varnish in place, ensuring the gloss remains high and the texture remains crisp.

Technical Advantages of LED UV for Embossing

Why choose LED over traditional UV for these specific processes? The answer lies in wavelength consistency and thermal management.

Deep Curing Performance

Tactile varnishes can be 50 to 250 microns thick. Traditional mercury lamps often cure the surface quickly but leave the bottom of the varnish “mushy.” This leads to poor adhesion and delamination.

LED UV light penetrates deeper into thick, clear layers. The 395nm wavelength is particularly effective at passing through high-build resins. This ensures that the bond between the varnish and the ink or substrate is secure.

Substrate Versatility

Narrow-web printers often work with unsupported films, shrink sleeves, and thermal papers. Heat from mercury lamps causes these materials to shrink, wrinkle, or discolor. LED UV lamps operate at much lower temperatures. By eliminating infrared radiation, LED allows for the production of tactile effects on delicate foils and thin PE films that were previously impossible to process inline.

Formulating Varnishes for LED Curing

You cannot simply use a standard mercury-bulb varnish with an LED system. The chemistry must match the light source.

Photoinitiator Selection

LED-compatible varnishes are formulated with photoinitiators that react specifically to the narrow UV-A band emitted by LEDs. When choosing a varnish for inline embossing, ensure it is optimized for 395nm output.

Viscosity and Flow Control

Tactile varnishes must have high thixotropic properties. They should flow easily through the screen or off the anilox but “set up” immediately once applied. LED curing’s rapid energy delivery is perfect for “freezing” these high-viscosity fluids before they can level out.

Overcoming Oxygen Inhibition

One of the hurdles in UV curing is oxygen inhibition. Oxygen in the air can interfere with the chemical reaction at the very surface of the varnish, leaving a tacky or “greasy” finish.

This is especially noticeable in tactile effects because of the large surface area of the varnish beads. To combat this, LED systems for high-end packaging often use high-intensity arrays. Increasing the “peak irradiance” (the brightness of the light) helps overwhelm the oxygen molecules at the surface, resulting in a hard, scratch-resistant finish.

Operational Efficiency and Cost Savings

Beyond the quality of the print, LED UV offers significant operational advantages for narrow-web and label converters.

- Reduced Energy Consumption: LED systems use up to 70% less electricity than mercury systems. Since tactile effects require high power for deep penetration, the savings are even more pronounced.

- Longer Lifespan: An LED cassette lasts over 20,000 hours, compared to 1,000 hours for a mercury bulb. This means fewer stops during a long run of embossed labels.

- No Ozone Production: LED UV does not generate ozone. This eliminates the need for complex extraction ducting, making the pressroom environment safer and easier to manage.

Precision Maintenance for Tactile Success

To maintain consistent tactile effects, the LED window must remain clean. In a flexo or offset environment, paper dust and ink mist can settle on the LED optics. Even a thin layer of dust can drop the UV output by 10%.

For tactile work, where curing the bottom of the varnish layer is critical, any drop in intensity can lead to failure. Implement a daily cleaning bridge for the LED heads using approved electronic cleaners. Monitor the UV output regularly with a radiometer designed for LED wavelengths.

The Future of Inline Textures

The integration of LED UV curing is transforming how we think about “specialty” printing. What used to be a complex, multi-stage process is now a standard inline capability.

As LED technology continues to evolve, we are seeing even higher power outputs. This will allow for even thicker tactile layers and faster press speeds. For the narrow-web and label industry, the ability to offer these premium features at a lower operational cost is a significant competitive advantage.

By focusing on the synergy between varnish chemistry, LED wavelength, and substrate stability, printers can produce stunning embossed effects that stand out on the shelf. The transition to LED is not just an environmental choice; it is a move toward higher precision and expanded creative possibilities in the printing industry.