Optimizing your printing press with UV curing systems unlocks a new level of efficiency and quality. This guide walks you through the setup process, focusing on narrow web, flexographic, offset, and label printing applications. We’ll cover the essentials of LED UV curing technology. Understanding these principles is key for seamless integration.

Understanding UV Curing Technology

UV curing uses ultraviolet light to instantly dry or “cure” inks and coatings. This process polymerizes liquid inks, transforming them into a solid, durable film. Traditional drying methods often involve heat, which can degrade substrates or slow down production. UV curing offers a faster, more energy-efficient alternative. LED UV lamps are the modern standard. They offer longer lifespan and lower energy consumption than older mercury vapor lamps. They also emit less heat, which is great for sensitive materials.

Benefits of UV Curing in Printing

Integrating UV curing systems brings significant advantages. You’ll see faster production speeds because inks dry instantly. This means less waiting time between processes. It also allows for immediate stacking of printed materials without smudging. Enhanced print durability is another major plus. UV-cured inks are highly resistant to abrasion, chemicals, and fading. This is crucial for labels and packaging that need to withstand harsh environments.

Furthermore, UV inks often offer superior color vibrancy and sharper details compared to conventional inks. The instant drying prevents ink spread. This results in crisper dot reproduction and cleaner print edges. For environmental considerations, UV inks are often formulated with low or zero VOCs (Volatile Organic Compounds). This makes them a more eco-friendly choice.

Choosing the Right UV Curing System

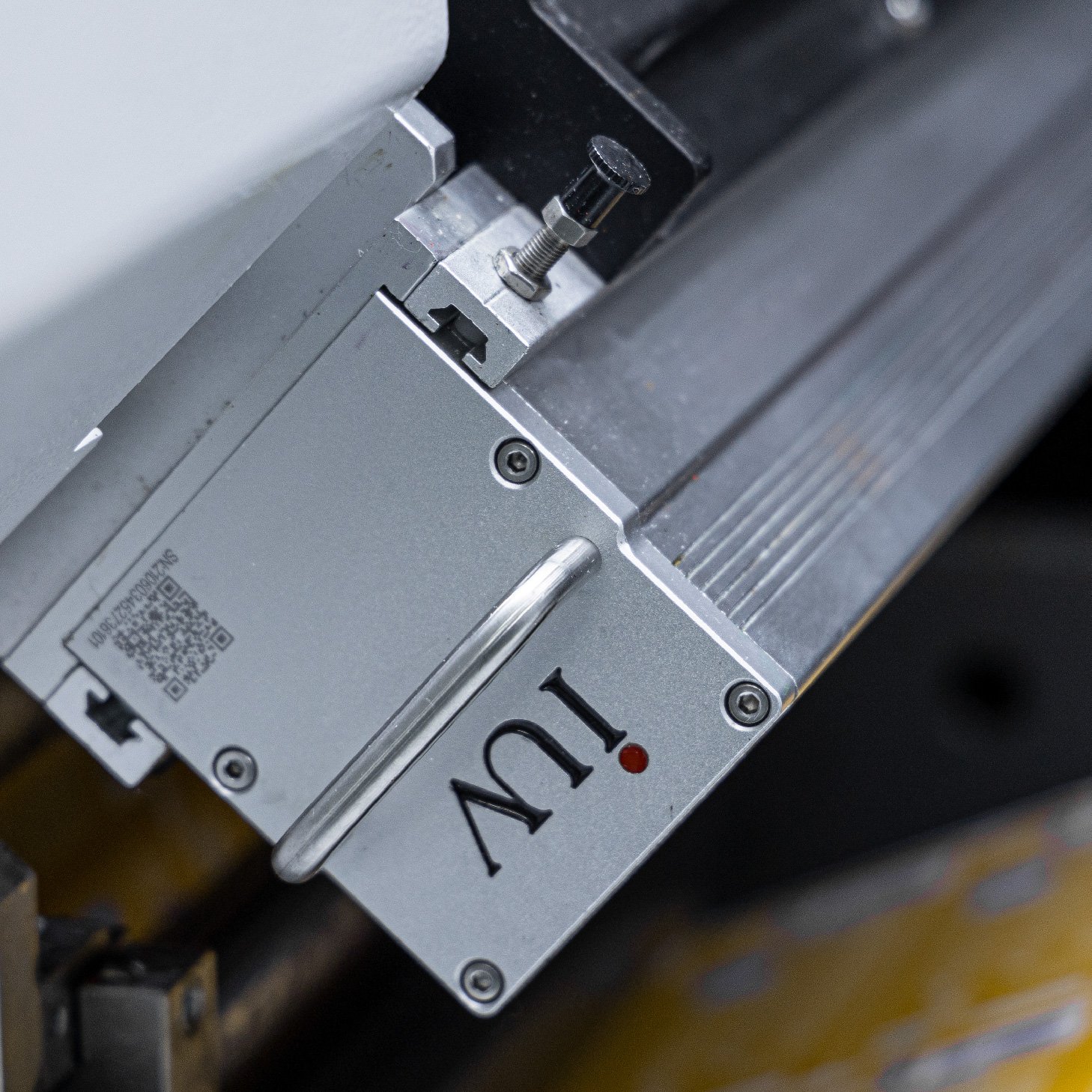

The selection of a UV curing system depends on your specific printing press and application. For narrow web presses, particularly in label and flexible packaging, compact LED UV systems are common. These systems are designed to fit within limited space. They offer targeted curing for high-speed operations.

Flexographic printing often benefits from UV curing due to its high speeds and the need for robust, scuff-resistant prints. The curing units are typically installed after each print station. This allows for a wide gamut of colors and special effects.

Offset printing, especially sheetfed, can also integrate UV curing. This is useful for high-quality, short-run jobs where immediate finishing is required. Offset UV curing requires careful consideration of ink transfer and substrate compatibility.

Key Components of a UV Curing System

A typical UV curing system includes the UV lamp(s), a power supply, and a cooling system. LED UV systems use solid-state diodes that emit UV light. These diodes are arranged in arrays to provide the necessary UV intensity. The power supply drives the LEDs, controlling their output.

Cooling is essential to maintain optimal operating temperatures. Overheating can reduce the lifespan of the LEDs and affect cure performance. Air cooling is common for smaller systems, while water cooling is used for higher-power applications. Reflectors are also a part of the system. They direct the UV light efficiently onto the substrate, maximizing cure depth and speed.

Installation Considerations

Proper installation is paramount for effective UV curing. The system must be mounted securely to the printing press. Alignment is critical. The UV lamps need to be positioned at the correct distance from the substrate. Too close, and you risk overheating or damaging the substrate. Too far, and the UV intensity will be insufficient for proper curing.

Ventilation is another important aspect. While LED UV systems produce less heat than older technologies, some heat is still generated. Adequate airflow around the curing unit helps dissipate this heat. Ensure the exhaust system, if present, is clear and functioning properly.

Curing Parameters and Optimization

Understanding cure parameters is vital for achieving consistent results. The two main parameters are UV dose and irradiance. UV dose is the total amount of UV energy delivered to the ink. It’s measured in millijoules per square centimeter (mJ/cm²). Irradiance is the power of the UV light source. It’s measured in milliwatts per square centimeter (mW/cm²).

The required UV dose depends on the ink formulation, the substrate type, and the printing speed. Different inks require different wavelengths and intensities for optimal curing. Always consult the ink manufacturer’s recommendations.

To optimize curing, start with the manufacturer’s recommended settings. Then, conduct test runs. Examine the cured ink for tackiness, scratch resistance, and color consistency. Adjust the UV lamp power, speed, or distance as needed. Small adjustments can often yield significant improvements.

Substrate and Ink Compatibility

Not all substrates and inks are created equal when it comes to UV curing. Most common printing substrates, including paper, board, and many plastics, work well with UV inks. However, some materials might have additives that can block UV light. Always test new substrates.

UV inks come in various formulations for different applications. Some are designed for high-gloss finishes, while others provide matte effects. There are also specialized UV inks for food packaging, which require specific certifications. Ensure you are using UV inks suitable for your intended application and compliant with relevant regulations.

Maintenance and Troubleshooting

Regular maintenance ensures your UV curing system operates at peak performance. Keep the UV lamps and reflectors clean. Dust and ink residue can block UV light, reducing curing efficiency. Follow the manufacturer’s guidelines for cleaning and replacement of components.

Common issues include incomplete curing, surface tackiness, or yellowing of the print. Incomplete curing might be due to insufficient UV dose, incorrect lamp alignment, or a contaminated lamp surface. Surface tackiness can sometimes be caused by oxygen inhibition, especially with certain free-radical curing inks. In such cases, using an inert gas or a different ink formulation might be necessary.

Yellowing can occur if the ink is overexposed to UV light or if the substrate itself is sensitive to UV radiation. Troubleshooting often involves systematically checking each parameter: lamp output, distance, speed, and ink properties.

The Future of UV Curing in Narrow Web Printing

The trend towards LED UV curing in narrow web printing is accelerating. LED technology offers significant advantages in terms of energy efficiency, lifespan, and environmental impact. As LED UV systems become more powerful and cost-effective, their adoption will continue to grow. This technology is pushing the boundaries of what’s possible in label and packaging printing. It enables faster turnaround times, higher quality, and more sustainable printing practices.