Thermal damage is the silent killer of print quality. Warped labels, discolored packaging, and brittle substrates cost printers time and money. Enter LED UV curing—a game-changer for label, flexo, offset, and narrow-web printing. Let’s unpack how this tech tackles heat-related flaws while boosting efficiency.

Why Heat Destroys Delicate Substrates

Traditional mercury-arc UV lamps blast materials with infrared (IR) radiation. Thin films, heat-sensitive plastics, and paper stocks buckle under temps exceeding 150°F. LED UV systems emit near-zero IR, curing inks at 95-110°F. Less heat means:

- Zero warping on PET labels

- No yellowing of white inks on BOPP films

- Consistent adhesion on shrink sleeves

A label printer switching to LED UV reported 37% fewer substrate rejects—heat distortion dropped from 12% to 0.8%.

LED UV vs. Conventional Curing: A Flexo Case Study

Flexo printers love LED for fast job changes and energy savings. But the real win? Preserving thin films in food packaging.

Problem: A snack bag printer using solvent-based inks battled curl on 40-micron polypropylene. Drying ovens at 185°F caused edge lift, jamming die-cutters.

Solution: Switching to LED-curable flexo inks eliminated ovens. Curing at 104°F kept films flat. Downtime fell by 22%, and ink costs dropped 18% (no solvent evaporation).

Offset Printers: Saving Paper from “Frying Pan” Syndrome

Sheetfed offset heats up. Literally. IR from UV lamps can toast paper at 140°F , causing:

- Fiber swelling → misregister

- Moisture loss → cockling

- Hickeys from dried spray powder

LED UV’s cool cure locks inks without cooking the sheet. A book printer using 80gsm paper slashed waste from 9% to 1.2% post-LED adoption.

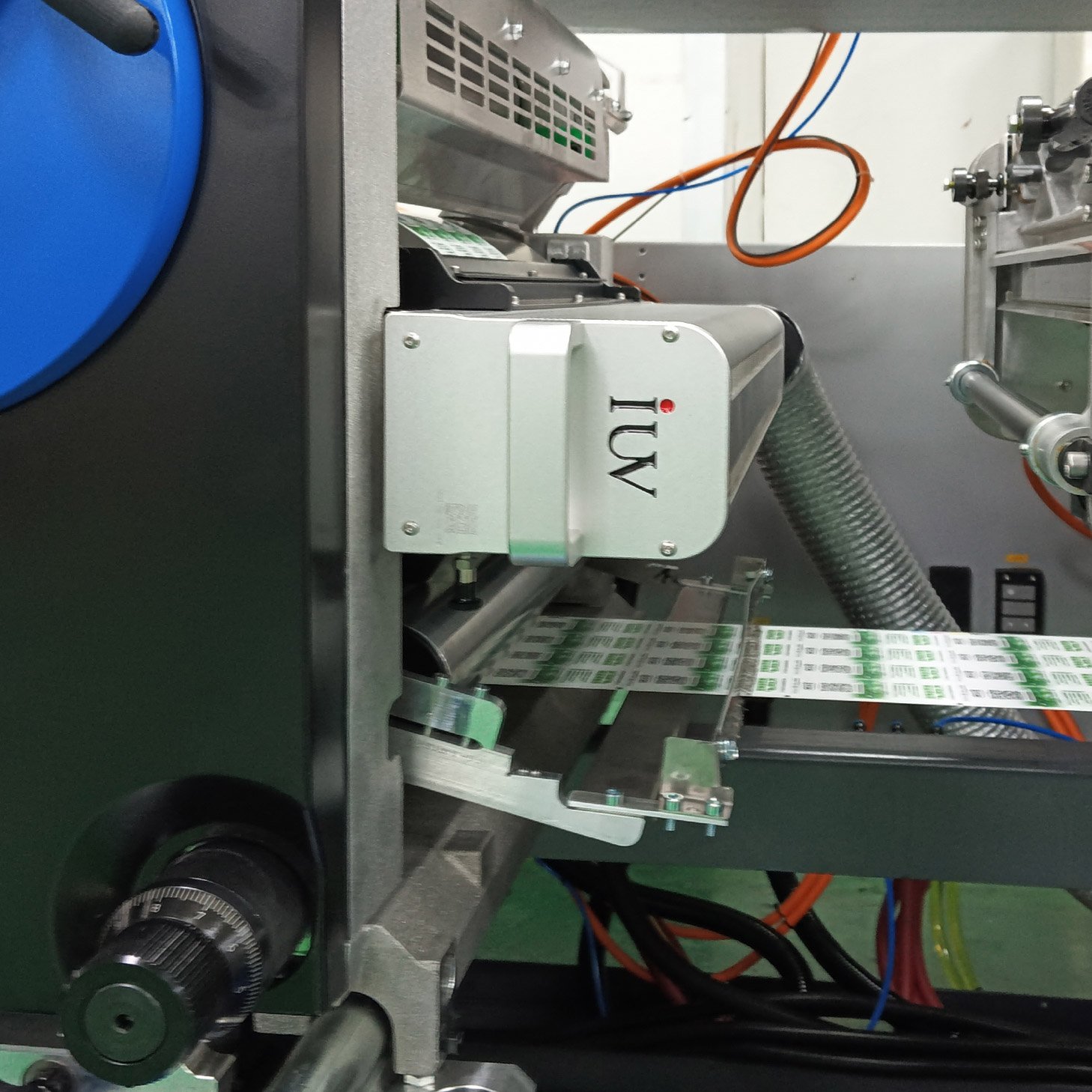

Narrow-Web’s Secret: LED UV on Pressure-Sensitive Labels

Narrow-web’s Achilles’ heel? Heat-sensitive adhesives. Hot curing weakens acrylics, causing:

- Edge ooze in summer

- Liner shrinkage → misregistration

LED UV’s targeted curing skips adhesive zones. A wine label producer cut liner waste by 31% by keeping adhesives below 100°F.

3 Rules for Choosing LED UV Systems

Not all LEDs are equal. Match specs to your substrates:

- Wavelength Matters: 365-395nm LEDs cure acrylates; 385-405nm for pigmented inks.

- Peak Irradiance: 8-12 W/cm² for opaque whites; 3-5 W/cm² for varnishes.

- Oxygen Inhibition: Nitrogen inerting or hybrid lamps? Depends on ink chemistry.

A test with 10mil PVC showed: 395nm LEDs cured 98% through, while 385nm stalled at 82%.

Future-Proofing with LED UV

As brands demand thinner, greener materials (compostable films, paper-based laminates), heat management isn’t optional. LED UV isn’t just a tool—it’s insurance against substrate obsolescence.

Printers adopting LED now report:

- 40% faster job turnover (no cooldown)

- 55% lower energy vs. mercury lamps

- 100% compatibility with heat-sensitive stocks

Bottom Line: Thermal damage isn’t a cost of doing business—it’s a solvable flaw. LED UV bridges the gap between harsh curing demands and fragile modern substrates. Whether you’re battling label curl or paper cockling, cold curing keeps your prints—and profits—intact.