The flexo printing industry is at the forefront of innovation, with new trends emerging each year that shape the future of printing.

- As we navigate through 2024, several key trends have solidified their positions, indicating their potential for long-term impact on the industry.

- Here’s an overview of the major flexo printing trends that are not just passing phases but are here to stay.

- 1. Sustainability and Eco-Friendly Practices

With growing environmental concerns, the push for sustainable printing practices continues to gain momentum.

Printers are adopting water-based inks, energy-efficient equipment, and recycling initiatives to reduce their carbon footprint.

- 2. UV LED Curing Technology

The shift from traditional mercury lamps to UV LED curing systems is well underway, offering significant energy savings, instant-on capabilities, and longer lifespans.

IUV’s advanced LED curing systems exemplify this trend, promoting both efficiency and environmental responsibility.

- 3. Digitalization and Automation

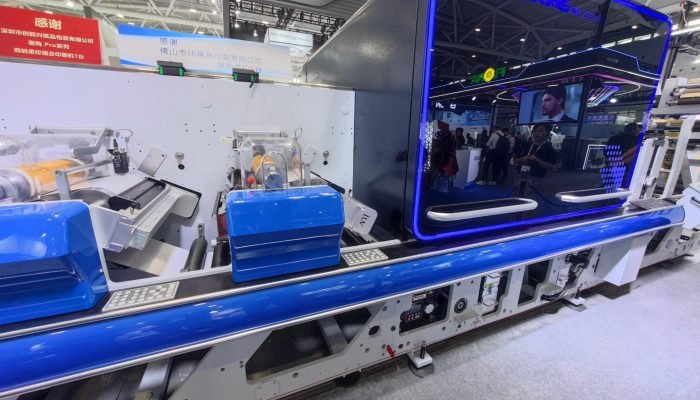

The integration of digital technologies and automation in flexo printing is transforming the industry.

From prepress automation to inline quality control, digital solutions are streamlining operations, reducing waste, and enhancing print consistency.

- 4. Intelligent Automation

Smart factories are becoming a reality with the implementation of intelligent automation.

This includes the use of AI for predictive maintenance, automated color management, and self-adjusting press settings for optimal performance.

- 5. Special Effects and Textured Printing

The demand for packaging with tactile and visual appeal is driving the adoption of special effects inks and textured printing techniques.

This trend is enhancing the sensory experience of consumers, adding value to brands.

- 6. Modular and Customizable Equipment

The need for flexibility in print production is leading to the development of modular and customizable printing equipment.

IUV’s modular power supply systems and curing lamps allow for tailored solutions that can adapt to changing market demands.

- 7. Data-Driven Decision Making

Printers are leveraging data analytics to optimize their operations, from monitoring press performance to predicting maintenance needs.

Real-time data is becoming a critical asset in driving efficiency and profitability.

- 8. Expanded Color Gamut

The pursuit of more vibrant and accurate color reproduction is leading to the adoption of extended color gamut printing.

This allows printers to capture a wider range of colors, meeting the high standards of brand owners.

- 9. Cloud-Based Solutions

Cloud technology is playing an increasingly important role in the printing industry, enabling remote monitoring, centralized management, and streamlined workflows.

IUV’s cloud-based remote control systems are a prime example of this trend.

- 10. Focus on Short Run and Personalized Printing

The market is demanding shorter run lengths and personalized prints.

Flexo printers are investing in technologies that allow for quick changeovers and customization, meeting the needs of an increasingly diverse customer base.

Conclusion

- These trends reflect the flexo printing industry’s ongoing commitment to innovation, sustainability, and efficiency.

- As the industry continues to evolve, embracing these trends will be crucial for printers aiming to stay competitive and meet the ever-changing demands of their customers.

- For more insights into the latest UV curing technologies and how they can enhance your printing operations, explore IUV’s UV Curing Technology.